A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed by a connecting rod and crank into rotational force for work. The term "steam engine" is most commonly applied to reciprocating engines as just described, although some authorities have also referred to the steam turbine and devices such as Hero's aeolipile as "steam engines". The essential feature of steam engines is that they are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

A turbine is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor.

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant, which is a kind of gas-fired power plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

The Rankine cycle is an idealized thermodynamic cycle describing the process by which certain heat engines, such as steam turbines or reciprocating steam engines, allow mechanical work to be extracted from a fluid as it moves between a heat source and heat sink. The Rankine cycle is named after William John Macquorn Rankine, a Scottish polymath professor at Glasgow University.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

A magnetohydrodynamic generator is a magnetohydrodynamic converter that transforms thermal energy and kinetic energy directly into electricity. An MHD generator, like a conventional generator, relies on moving a conductor through a magnetic field to generate electric current. The MHD generator uses hot conductive ionized gas as the moving conductor. The mechanical dynamo, in contrast, uses the motion of mechanical devices to accomplish this.

A feedwater heater is a power plant component used to pre-heat water delivered to a steam generating boiler. Preheating the feedwater reduces the irreversibilities involved in steam generation and therefore improves the thermodynamic efficiency of the system. This reduces plant operating costs and also helps to avoid thermal shock to the boiler metal when the feedwater is introduced back into the steam cycle.

A thermal power station, also known as a thermal power plant, is a type of power station in which the heat energy generated from various fuel sources is converted to electrical energy. The heat from the source is converted into mechanical energy using a thermodynamic power cycle. The most common cycle involves a working fluid heated and boiled under high pressure in a pressure vessel to produce high-pressure steam. This high pressure-steam is then directed to a turbine, where it rotates the turbine's blades. The rotating turbine is mechanically connected to an electric generator which converts rotary motion into electricity. Fuels such as natural gas or oil can also be burnt directly in gas turbines, skipping the steam generation step. These plants can be of the open cycle or the more efficient combined cycle type.

A binary cycle is a method for generating electrical power from geothermal resources and employs two separate fluid cycles, hence binary cycle. The primary cycle extracts the geothermal energy from the reservoir, and secondary cycle converts the heat into work to drive the generator and generate electricity.

A steam–electric power station is a power station in which the electric generator is steam-driven: water is heated, evaporates, and spins a steam turbine which drives an electric generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam–electric power plants is due to the different fuel sources.

A gas-fired power plant, sometimes referred to as gas-fired power station, natural gas power plant, or methane gas power plant, is a thermal power station that burns natural gas to generate electricity. Gas-fired power plants generate almost a quarter of world electricity and are significant sources of greenhouse gas emissions. However, they can provide seasonal, dispatchable energy generation to compensate for variable renewable energy deficits, where hydropower or interconnectors are not available. In the early 2020s batteries became competitive with gas peaker plants.

The Littlebrook Power Station were a series of four oil and coal-fired power stations situated on the south bank of the River Thames, next to the Queen Elizabeth 2 Bridge and the Dartford Tunnel in Dartford, Kent. The final power station, Littlebrook D, ceased operating in March 2015, and has now been demolished.

Little Barford Power Station is a gas-fired power station just north of the village of Little Barford in Bedfordshire, England. It lies just south of the A428 St Neots bypass and east of the Wyboston Leisure Park. The River Great Ouse runs alongside. It was formerly the site of two coal-fired power stations, now demolished. The station is operated by RWE.

Great Yarmouth Power Station is combined cycle gas turbine power station on South Denes Road in Great Yarmouth in Norfolk, England, with a maximum output of 420 MW electricity, opened in 2001. It is built on the site of an oil-fired power station, built in 1958 and closed and demolished in the 1990s. A coal-fired power station was built in Great Yarmouth in 1894 and operated until 1961. The station is operated by RWE.

Carrington Power Station is a combined cycle gas turbine power station, which was completed in Autumn 2016 and began commercial operation on 18 September 2016. It is located on the site of a former coal-fired power station, close to the villages of Carrington and Partington in the Greater Manchester Area and 12 km (7.5 mi) southwest of Manchester City Centre. The Manchester Ship Canal and the River Mersey run alongside the site, in Trafford, Greater Manchester, in North West England.

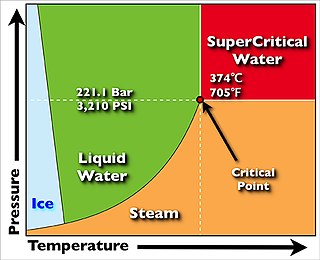

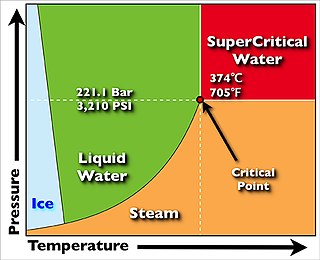

A supercritical steam generator is a type of boiler that operates at supercritical pressure and temperature, frequently used in the production of electric power.

Repowering is the process of replacing older power stations with newer ones that either have a greater nameplate capacity or more efficiency which results in a net increase of power generated. Repowering can happen in several different ways. It can be as small as switching out and replacing a boiler, to as large as replacing the entire system to create a more powerful system entirely. There are many upsides to repowering.

The Hygroscopic cycle is a thermodynamic cycle converting thermal energy into mechanical power by the means of a steam turbine. It is similar to the Rankine cycle using water as the motive fluid but with the novelty of introducing salts and their hygroscopic properties for the condensation. The salts are desorbed in the boiler or steam generator, where clean steam is released and superheated in order to be expanded and generate power through the steam turbine. Boiler blowdown with the concentrated hygroscopic compounds is used thermally to pre-heat the steam turbine condensate, and as reflux in the steam-absorber.

Butibori Power Project is a coal-based thermal power plant located at Butibori near Nagpur in the Indian state of Maharashtra. The power plant is operated by the Reliance Power.