Related Research Articles

In physics, attenuation or, in some contexts, extinction is the gradual loss of flux intensity through a medium. For instance, dark glasses attenuate sunlight, lead attenuates X-rays, and water and air attenuate both light and sound at variable attenuation rates.

Mode-locking is a technique in optics by which a laser can be made to produce pulses of light of extremely short duration, on the order of picoseconds (10−12 s) or femtoseconds (10−15 s). A laser operated in this way is sometimes referred to as a femtosecond laser, for example in modern refractive surgery. The basis of the technique is to induce a fixed-phase relationship between the longitudinal modes of the laser's resonant cavity. Constructive interference between these modes can cause the laser light to be produced as a train of pulses. The laser is then said to be 'phase-locked' or 'mode-locked'.

A perforation is a small hole in a thin material or web. There is usually more than one perforation in an organized fashion, where all of the holes collectively are called a perforation. The process of creating perforations is called perforating, which involves puncturing the workpiece with a tool.

Soundproofing is any means of reducing the sound pressure with respect to a specified sound source and receptor. There are several basic approaches to reducing sound: increasing the distance between source and receiver, using noise barriers to reflect or absorb the energy of the sound waves, using damping structures such as sound baffles, or using active antinoise sound generators.

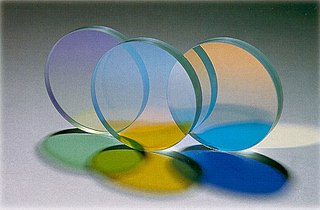

In the field of optics, transparency is the physical property of allowing light to pass through the material without appreciable scattering of light. On a macroscopic scale, the photons can be said to follow Snell's Law. Translucency allows light to pass through, but does not necessarily follow Snell's law; the photons can be scattered at either of the two interfaces, or internally, where there is a change in index of refraction. In other words, a translucent material is made up of components with different indices of refraction. A transparent material is made up of components with a uniform index of refraction. Transparent materials appear clear, with the overall appearance of one color, or any combination leading up to a brilliant spectrum of every color. The opposite property of translucency is opacity.

Reflection is the change in direction of a wavefront at an interface between two different media so that the wavefront returns into the medium from which it originated. Common examples include the reflection of light, sound and water waves. The law of reflection says that for specular reflection the angle at which the wave is incident on the surface equals the angle at which it is reflected. Mirrors exhibit specular reflection.

The Noise Reduction Coefficient is a single number value ranging from 0.0-1.0 that describes the average sound absorption performance of a material. An NRC of 0.0 indicates the object does not attenuate mid-frequency sounds, but rather reflects sound energy. This is more conceptual than physically achievable: even very thick concrete walls will attenuate sound and may have an NRC of 0.05. Conversely, an NRC of 1.0 indicates that the material provides an acoustic surface area that is equivalent to its physical, two-dimensional surface area. This rating is common of thicker, porous sound absorptive materials such as 2"-thick fabric-wrapped fiberglass panel. Materials can achieve NRC values greater than 1.00. This is a shortcoming of the test procedure and a limitation of how acousticians define a square unit of absorption, and not a characteristic of the material itself.

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat. Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1.

Architectural acoustics is the science and engineering of achieving a good sound within a building and is a branch of acoustical engineering. The first application of modern scientific methods to architectural acoustics was carried out by the American physicist Wallace Sabine in the Fogg Museum lecture room. He applied his new found knowledge to the design of Symphony Hall, Boston.

In the field of acoustics, a diaphragm is a transducer intended to inter-convert mechanical vibrations to sounds, or vice versa. It is commonly constructed of a thin membrane or sheet of various materials, suspended at its edges. The varying air pressure of sound waves imparts mechanical vibrations to the diaphragm which can then be converted to some other type of signal; examples of this type of diaphragm are found in microphones and the human eardrum. Conversely a diaphragm vibrated by a source of energy beats against the air, creating sound waves. Examples of this type of diaphragm are loudspeaker cones and earphone diaphragms and are found in air horns.

Acoustic absorption refers to the process by which a material, structure, or object takes in sound energy when sound waves are encountered, as opposed to reflecting the energy. Part of the absorbed energy is transformed into heat and part is transmitted through the absorbing body. The energy transformed into heat is said to have been 'lost'.

Noise control or noise mitigation is a set of strategies to reduce noise pollution or to reduce the impact of that noise, whether outdoors or indoors.

Room modes are the collection of resonances that exist in a room when the room is excited by an acoustic source such as a loudspeaker. Most rooms have their fundamental resonances in the 20 Hz to 200 Hz region, each frequency being related to one or more of the room's dimensions or a divisor thereof. These resonances affect the low-frequency low-mid-frequency response of a sound system in the room and are one of the biggest obstacles to accurate sound reproduction.

Acoustic waves are a type of energy propagation through a medium by means of adiabatic compression and decompression. Important quantities for describing acoustic waves are acoustic pressure, particle velocity, particle displacement and acoustic intensity. Acoustic waves travel with a characteristic acoustic velocity that depends on the medium they're passing through. Some examples of acoustic waves are audible sound from a speaker, ground movement from an earthquake, or ultrasound used for medical imaging.

Building insulation materials are the building materials which form the thermal envelope of a building or otherwise reduce heat transfer.

Bass traps are acoustic energy absorbers which are designed to damp low frequency sound energy with the goal of attaining a flatter low frequency (LF) room response by reducing LF resonances in rooms. They are commonly used in recording studios, mastering rooms, home theatres and other rooms built to provide a critical listening environment. Like all acoustically absorptive devices, they function by turning sound energy into heat through friction.

Acoustic quieting is the process of making machinery quieter by damping vibrations to prevent them from reaching the observer. Machinery vibrates, causing sound waves in air, hydroacoustic waves in water, and mechanical stresses in solid matter. Quieting is achieved by absorbing the vibrational energy or minimizing the source of the vibration. It may also be redirected away from the observer.

Perforated metal, also known as perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched using CNC technology or in some cases laser cutting to create different holes sizes, shapes and patterns. Materials used to manufacture perforated metal sheets include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, Inconel, titanium, plastic, and more.

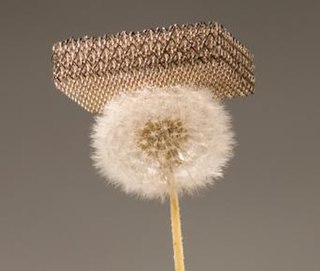

A metallic microlattice is a synthetic porous metallic material consisting of an ultra-light metal foam. With a density as low as 0.99 mg/cm3 (0.00561 lb/ft3), it is one of the lightest structural materials known to science. It was developed by a team of scientists from California-based HRL Laboratories, in collaboration with researchers at University of California, Irvine and Caltech, and was first announced in November 2011. The prototype samples were made from a nickel-phosphorus alloy. In 2012, the microlattice prototype was declared one of 10 World-Changing Innovations by Popular Mechanics. Metallic microlattice technology has numerous potential applications in automotive and aeronautical engineering. A detailed comparative review study among other types of metallic lattice structures showed them to be beneficial for light-weighting purposes but expensive to manufacture.

Foam glass is a porous glass foam material. Its advantages as a building material include its light weight, high strength, and thermal and acoustic insulating properties. It is made by heating a mixture of crushed or granulated glass and a blowing agent such as carbon or limestone. Near the melting point of the glass, the blowing agent releases a gas, producing a foaming effect in the glass. After cooling the mixture hardens into a rigid material with gas-filled closed-cell pores comprising a large portion of its volume.

References

- ↑ Daa-You Maa (1998). "Potentials of micro perforated absorbers". Journal of the Acoustical Society of America . 104 (5): 2861–2866. Bibcode:1998ASAJ..104.2861M. doi:10.1121/1.423870.

- ↑ Helmut V. Fuchs, Xueqin Zha (2006). "Micro Perforated Structures as Sound Absorbers - A Review and Outlook". Acta Acustica United with Acustica. 92: 139–146.

- ↑ Hans Bodén, Ying Guo, Hüseyin Bora Tözün (8–10 May 2006). "Experimental Investigation of Nonlinear Acoustic Properties for Perforates". 12th AIAA Aero Acoustic Conference. Cambridge, Massachusetts.CS1 maint: multiple names: authors list (link)