A lubricant is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity.

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings. Thus, it is possible for some fluid bearings to have near-zero wear if operated correctly.

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

A magnetic bearing is a type of bearing that supports a load using magnetic levitation. Magnetic bearings support moving parts without physical contact. For instance, they are able to levitate a rotating shaft and permit relative motion with very low friction and no mechanical wear. Magnetic bearings support the highest speeds of any kind of bearing and have no maximum relative speed.

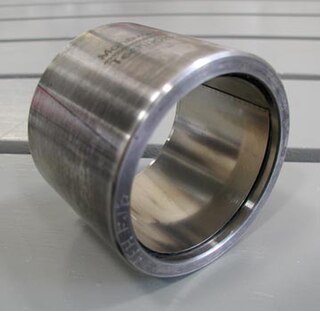

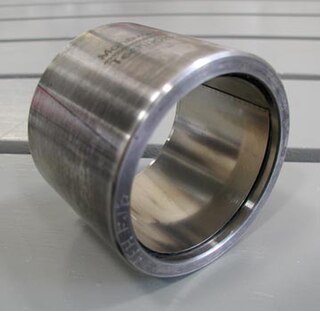

A plain bearing, or more commonly sliding contact bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

A foil bearing, also known as a foil-air bearing, is a type of air bearing. A shaft is supported by a compliant, spring-loaded foil journal lining. Once the shaft is spinning fast enough, the working fluid pushes the foil away from the shaft so that no contact occurs. The shaft and foil are separated by the air's high pressure, which is generated by the rotation that pulls gas into the bearing via viscosity effects. The high speed of the shaft with respect to the foil is required to initiate the air gap, and once this has been achieved, no wear occurs. Unlike aerostatic or hydrostatic bearings, foil bearings require no external pressurisation system for the working fluid, so the hydrodynamic bearing is self-starting.

Microturbines are 25 to 500 kilowatt gas turbines evolved from piston engine turbochargers, aircraft auxiliary power units (APU) or small jet engines, the size of a refrigerator. Early turbines of 30-70 kW grew to 200-250 kW.

Hooshang Heshmat is the CEO, 1994 till Present and co-founder of Mohawk Innovative Technology. The company researches and develops green technology for integration into turbomachinery. Heshmat is a fellow in both the American Society of Mechanical Engineers (ASME), and the Society of Tribologists and Lubrication Engineers. In 2007, Heshmat received the Mayo D. Hersey Award, in recognition of his "contributions over a substantial period of time to the advancement of the science and engineering of tribology". In 2008, Heshmat received the International Award from the Society of Tribologists and Lubrication Engineers.

Condition monitoring is the process of monitoring a parameter of condition in machinery, in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance. The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent consequential damages and avoid its consequences. Condition monitoring has a unique benefit in that conditions that would shorten normal lifespan can be addressed before they develop into a major failure. Condition monitoring techniques are normally used on rotating equipment, auxiliary systems and other machinery, while periodic inspection using non-destructive testing (NDT) techniques and fit for service (FFS) evaluation are used for static plant equipment such as steam boilers, piping and heat exchangers.

A rotary-screw compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. These compressors are common in industrial applications and replace more traditional piston compressors where larger volumes of compressed gas are needed, e.g. for large refrigeration cycles such as chillers, or for compressed air systems to operate air-driven tools such as jackhammers and impact wrenches. For smaller rotor sizes the inherent leakage in the rotors becomes much more significant, leading to this type of mechanism being less suitable for smaller compressors than piston compressors.

Vapour-compression refrigeration or vapor-compression refrigeration system (VCRS), in which the refrigerant undergoes phase changes, is one of the many refrigeration cycles and is the most widely used method for air-conditioning of buildings and automobiles. It is also used in domestic and commercial refrigerators, large-scale warehouses for chilled or frozen storage of foods and meats, refrigerated trucks and railroad cars, and a host of other commercial and industrial services. Oil refineries, petrochemical and chemical processing plants, and natural gas processing plants are among the many types of industrial plants that often utilize large vapor-compression refrigeration systems. Cascade refrigeration systems may also be implemented using two compressors.

Elliott Company designs, manufactures, installs, and services turbo-machinery for prime movers and rotating machinery. Headquartered in Jeannette, Pennsylvania, Elliott Company is a wholly owned subsidiary of the Japan-based company, Ebara Corporation, and is a unit of Elliott Group, Ebara Corporation's worldwide turbomachinery business. Elliott Group employs more than 2000 employees worldwide at 32 locations, with approximately 900 in Jeannette.

Albert Kingsbury was an American engineer, inventor and entrepreneur. He was responsible for over fifty patents obtained between the years 1902 to 1930. Kingsbury is most famous for his hydrodynamic thrust bearing which uses a thin film of oil to support weights of up to 220 tons. This bearing extended the service life of many types of machinery during the early 20th century. It was primarily outfitted on Navy ships during World War I and World War II.

The exoskeletal engine (ESE) is a concept in turbomachinery design. Current gas turbine engines have central rotating shafts and fan-discs and are constructed mostly from heavy metals. They require lubricated bearings and need extensive cooling for hot components. They are also subject to severe imbalance that could wipe out the whole rotor stage, are prone to high- and low-cycle fatigue, and subject to catastrophic failure due to disc bursts from high tensile loads, consequently requiring heavy containment devices. To address these limitations, the ESE concept turns the conventional configuration inside-out and utilizes a drum-type rotor design for the turbomachinery in which the rotor blades are attached to the inside of a rotating drum instead of radially outwards from a shaft and discs. Multiple drum rotors could be used in a multi-spool design.

Spiral groove bearings are self-acting, or hydrodynamic bearings used to reduce friction and wear without the use of pressurized lubricants. They have this ability due to special patterns of grooves. Spiral groove bearings are self-acting because their own rotation builds up the pressure needed to separate the bearing surfaces. For this reason, they are also contactless bearings.

GGB, formerly Glacier Garlock Bearings, then GGB Bearing Technology manufactures self-lubricating, prelubricated plain bearings and tribological polymer coating for various industries and applications. It has production facilities in the U.S., Germany, France, Slovakia, Brazil and China. The company is a subsidiary of EnPro Industries. The company manufactures metal-polymer bearings, engineered plastics bearings, fiber reinforced composite bushings, metal and bimetal bearings & thrust plates and bearing assemblies.

An inverter compressor is a gas compressor that is operated with an inverter.

Air bearings are fluid bearings that use a thin film of pressurized gas to provide a low friction load-bearing interface between surfaces. The two surfaces do not touch, thus avoiding the traditional bearing-related problems of friction, wear, particulates, and lubricant handling, and offer distinct advantages in precision positioning, such as lacking backlash and static friction, as well as in high-speed applications. Space craft simulators now most often use air bearings and 3-D printers are now used to make air-bearing-based attitude simulators for CubeSat satellites.