Hancock is a city in the Upper Peninsula of the U.S. state of Michigan. The population of Hancock was 4,501 at the 2020 census. The city is located within Houghton County, and is situated upon the Keweenaw Waterway, a channel of Lake Superior that cuts across the Keweenaw Peninsula. Hancock is located across the Keweenaw Waterway from the city of Houghton, and is connected to that city by the Portage Lake Lift Bridge. The city is located within Michigan's Copper Country region.

Ahmeek is a village in Keweenaw County in the U.S. state of Michigan. The village is located within Allouez Township. The population was 127 at the 2020 census. At 0.07 square miles (0.18 km2), it is the smallest municipality in Michigan by land area, and is the only incorporated municipality in Keweenaw County.

The Minesota Mine is a former copper mine near Rockland, Ontonagon County in the Upper Peninsula of the U.S. state of Michigan. The Minesota was one of the most productive and famous early mines in the Michigan Copper Country.

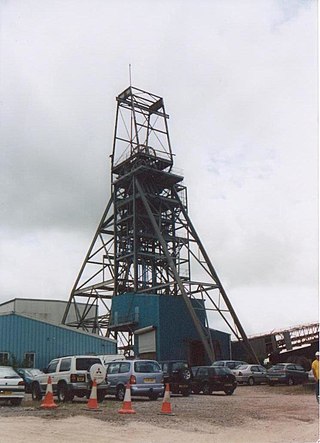

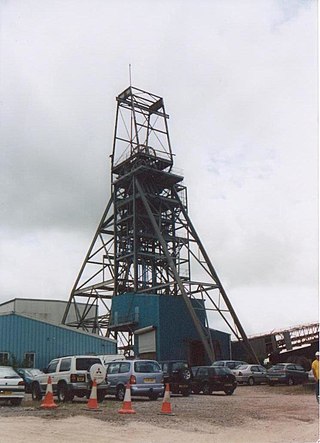

The Quincy Mine is an extensive set of copper mines located near Hancock, Michigan. The mine was owned by the Quincy Mining Company and operated between 1846 and 1945, although some activities continued through the 1970s. The Quincy Mine was known as "Old Reliable," as the Quincy Mine Company paid a dividend to investors every year from 1868 through 1920. The Quincy Mining Company Historic District is a United States National Historic Landmark District; other Quincy Mine properties nearby, including the Quincy Mining Company Stamp Mills, the Quincy Dredge Number Two, and the Quincy Smelter are also historically significant.

Keweenaw National Historical Park is a unit of the U.S. National Park Service. Established in 1992, the park celebrates the life and history of the Keweenaw Peninsula in the Upper Peninsula of the U.S. state of Michigan. It is a federal-local cooperative park made up of two primary units, the Calumet Unit and the Quincy Unit, and almost two dozen cooperating "Heritage Sites" located on federal, state, and privately owned land in and around the Keweenaw Peninsula. The National Park Service owns approximately 1,700 acres (690 ha) in the Calumet and Quincy Units. Units are located in Baraga, Houghton, Keweenaw, and Ontonagon counties.

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has pioneered several significant mining industry innovations, including the Isa Process copper refining technology, the Isasmelt smelting technology, and the IsaMill fine grinding technology, and it also commercialized the Jameson Cell column flotation technology.

The Calumet and Hecla Mining Company was a major copper-mining company based within Michigan's Copper Country. In the 19th century, the company paid out more than $72 million in shareholder dividends, more than any other mining company in the United States during that period.

In Michigan, copper mining became an important industry in the 19th and early 20th centuries. Its rise marked the start of copper mining as a major industry in the United States.

South Crofty is a metalliferous tin and copper mine located in the village of Pool, Cornwall, England. An ancient mine, it has seen production for over 400 years, and extends almost two and a half miles across and 3,000 feet (910 m) down and has mined over 40 lodes. Evidence of mining activity in South Crofty has been dated back to 1592, with full-scale mining beginning in the mid-17th century. The mine went into serious decline after 1985 and eventually closed in 1998. After several changes of ownership, South Crofty is owned by Cornish Metals Inc, which is working to re-open the mine, as of November 2022, having received a permit for dewatering the mine.

The Sunshine Mine is located between the cities of Kellogg and Wallace in northern Idaho. It has been one of the world's largest and most profitable silver mines, having produced over 360 million ounces of silver by 2001.

The Copper Country strike of 1913–1914 was a major strike affecting all copper mines in the Copper Country of Michigan. The strike, organized by the Western Federation of Miners, was the first unionized strike within the Copper Country. It was called to achieve goals of shorter work days, higher wages, union recognition, and to maintain family mining groups. The strike lasted just over nine months, including the Italian Hall disaster on Christmas Eve, and ended with the union being effectively driven out of the Keweenaw Peninsula. While unsuccessful, the strike is considered a turning point in the history of the Copper Country.

The Cliff mine was the first successful copper mine in the Copper Country of the state of Michigan in the United States. The mine is at the now-abandoned town of Clifton in Keweenaw County. Mining began in 1845, and the Cliff was the most productive copper mine in the United States from 1845 through 1854. Large-scale mining stopped in 1878.

The Smith–Dengler House is a private home located at 58555 US 41 in Wolverine, Calumet Charter Township, Michigan, United States. It was listed on the National Register of Historic Places in 2008.

The Quincy Dredge Number Two is a dredge currently sunk in shallow water in Torch Lake, across M-26 from the Quincy Mining Company Stamp Mills Historic District and just east of Mason in Osceola Township. It was constructed to reclaim stamping sand from the lake for further processing, and was designated a Michigan State Historic Site in 1978.

The Michigan Smelter was a copper smelter located at Cole's Creek on the Keweenaw Waterway north-west of Houghton, Michigan near the old Atlantic mill. The smelter was created in 1903-4 as a joint effort between the Copper Range Company and Stanton group of mines. An Atlantic dam on the site was reused by the smelter as a water source. In 1905, the smelter broke a world record by casting 292,000 pounds of fine copper in seven hours with a single furnace and only ten men. The smelter operated through World War II and stopped all operations in 1948.

Mohawkite is a rare rock consisting of mixtures of arsenic, silver, nickel, skutterudite and copper, with the formula Cu3As up to Cu6As, and the most desirable material was usually found in white quartz matrix. It has a hardness of 3–3.5 and a metallic luster. It is named after the Mohawk Mine, where it was originally found. Colors range from brassy-yellow to metallic gray, and sometimes will have a blue or greenish surface tarnish. These colors come from its two main ingredients, the arsenic-rich copper minerals algodonite and domeykite. Its color may resemble pyrrhotite, but unlike pyrrhotite, mohawkite is not magnetic.

OK Mine & Smelter is a heritage-listed mine at Kitoba Holding, Bellevue, Shire of Mareeba, Queensland, Australia. It was built from 1902 to 1942. It was added to the Queensland Heritage Register on 2 October 1996.

Champion-Providence Mine was a consolidation of two adjoining gold mines in Nevada City, California subsequent to the California Gold Rush. After it became the Champion Group following annexation of additional adjacent mining concerns, it became one of the two most productive mining groups in the Nevada City Mining District, alongside the North Star Mine, which purchased it in 1911. The Champion-Providence Mine closed in 1920.

Gordon Lake Mine was an underground copper mine near Werner Lake in the Kenora District of Ontario Canada.

The Silver Hill Mine was the first silver mine in the United States, later used primarily as a source of lead and zinc. Discovered during the Carolina gold rush at a Davidson County, North Carolina location later named Silver Hill, operations began at the site in 1839 under the Washington Mining Company. Increasing difficulties extracting the silver from ore heavy in lead and zinc led to the introduction of various new metallurgical processes and equipment. These were unable to fully stem losses of silver in refinement, and an increasingly convoluted production chain led to closure of the mine in 1852.