Structural geology is the study of the three-dimensional distribution of rock units with respect to their deformational histories. The primary goal of structural geology is to use measurements of present-day rock geometries to uncover information about the history of deformation (strain) in the rocks, and ultimately, to understand the stress field that resulted in the observed strain and geometries. This understanding of the dynamics of the stress field can be linked to important events in the geologic past; a common goal is to understand the structural evolution of a particular area with respect to regionally widespread patterns of rock deformation due to plate tectonics.

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, denoted by a single letter, that use different loads or indenters. The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale . When testing metals, indentation hardness correlates linearly with tensile strength.

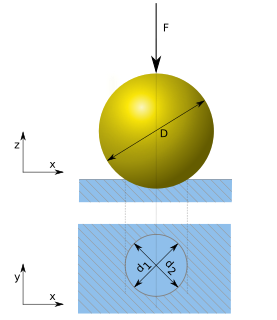

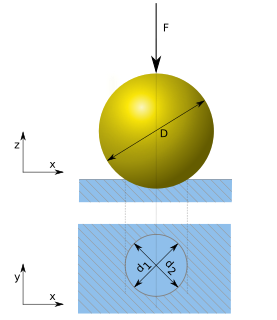

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.

A superhard material is a material with a hardness value exceeding 40 gigapascals (GPa) when measured by the Vickers hardness test. They are virtually incompressible solids with high electron density and high bond covalency. As a result of their unique properties, these materials are of great interest in many industrial areas including, but not limited to, abrasives, polishing and cutting tools, disc brakes, and wear-resistant and protective coatings.

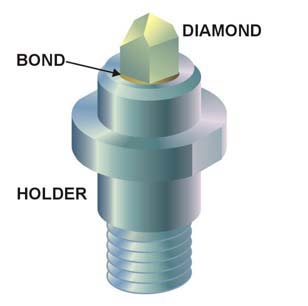

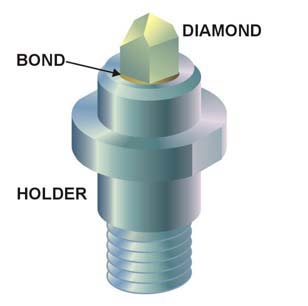

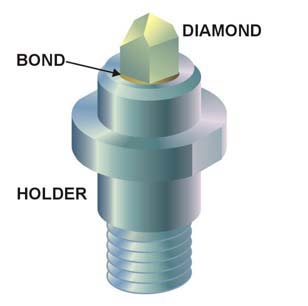

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe a material's ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). The hardness number can be converted into units of pascals, but should not be confused with pressure, which uses the same units. The hardness number is determined by the load over the surface area of the indentation and not the area normal to the force, and is therefore not pressure.

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale.

The Knoop hardness test is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known load, for a specified dwell time, and the resulting indentation is measured using a microscope. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1 and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge. The depth of the indentation can be approximated as 1/30 of the long dimension. The Knoop hardness HK or KHN is then given by the formula:

Nanotribology is the branch of tribology that studies friction, wear, adhesion and lubrication phenomena at the nanoscale, where atomic interactions and quantum effects are not negligible. The aim of this discipline is characterizing and modifying surfaces for both scientific and technological purposes.

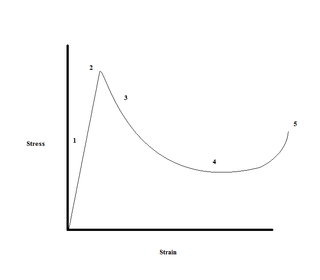

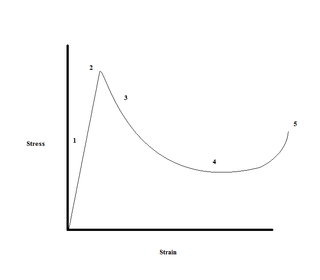

Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, there are different measurements of hardness: scratch hardness, indentation hardness, and rebound hardness.

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material.

The Shore durometer is a device for measuring the hardness of a material, typically of polymers, elastomers, and rubbers.

A Berkovich tip is a type of nanoindenter tip used for testing the indentation hardness of a material. It is a three-sided pyramid which is geometrically self-similar. The popular Berkovich now has a very flat profile, with a total included angle of 142.3 degrees and a half angle of 65.27 degrees, measured from the axis to one of the pyramid flats. This Berkovich tip has the same projected area-to-depth ratio as a Vickers indenter. The original tip shape was invented by Russian scientist E.S. Berkovich in the USSR c. 1950, which has a half angle of 65.03 degrees.

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 µm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentions. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, , is defined as the maximum load, divided by the projected area of the indent, .

Meyer's law is an empirical relation between the size of a hardness test indentation and the load required to leave the indentation. The formula was devised by Eugene Meyer of the Materials Testing Laboratory at the Imperial School of Technology, Charlottenburg, Germany, circa 1908.

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces.

The fiber pushout test is a mechanical test performed on composite materials where a fiber is mechanically pushed out of the material. This test is carried out with the purpose of measuring the matrix/fiber interface de-bonding energy and the effects of frictional sliding between the matrix and the fiber.

Materials that are used for biomedical or clinical applications are known as biomaterials. The following article deals with fifth generation biomaterials that are used for bone structure replacement. For any material to be classified for biomedical application three requirements must be met. The first requirement is that the material must be biocompatible; it means that the organism should not treat it as a foreign object. Secondly, the material should be biodegradable ; the material should harmlessly degrade or dissolve in the body of the organism to allow it to resume natural functioning. Thirdly, the material should be mechanically sound; for the replacement of load bearing structures, the material should possess equivalent or greater mechanical stability to ensure high reliability of the graft.

The Korsunsky work-of-indentation approach is a method of extracting a values of hardness and stiffness for a small volume of material from indentation test data.

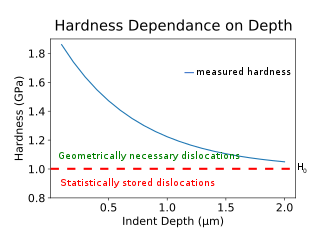

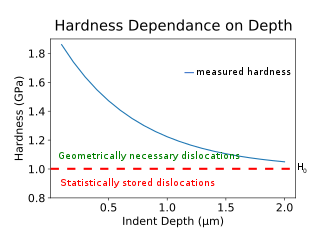

The indentation size effect (ISE) is the observation that hardness tends to increase as the indent size decreases at small scales. When an indent is created during material testing, the hardness of the material is not constant. At the small scale, materials will actually be harder than at the macro-scale. For the conventional indentation size effect, the smaller the indentation, the larger the difference in hardness. The effect has been seen through nanoindentation and microindentation measurements at varying depths. Dislocations increase material hardness by increasing flow stress through dislocation blocking mechanisms. Materials contain statistically stored dislocations (SSD) which are created by homogeneous strain and are dependent upon the material and processing conditions. Geometrically necessary dislocations (GND) on the other hand are formed, in addition to the dislocations statistically present, to maintain continuity within the material.