Related Research Articles

Agecroft Colliery was a coal mine on the Manchester Coalfield that opened in 1844 in the Agecroft district of Pendlebury, Lancashire, England. It exploited the coal seams of the Middle Coal Measures of the Lancashire Coalfield. The colliery had two spells of use; the first between 1844 and 1932, when the most accessible coal seams were exploited, and a second lease of life after extensive development in the late 1950s to access the deepest seams.

Wet Earth Colliery was a coal mine located on the Manchester Coalfield, in Clifton, Greater Manchester. The colliery site is now the location of Clifton Country Park. The colliery has a unique place in British coal mining history; apart from being one of the earliest pits in the country, it is the place where engineer James Brindley made water run uphill.

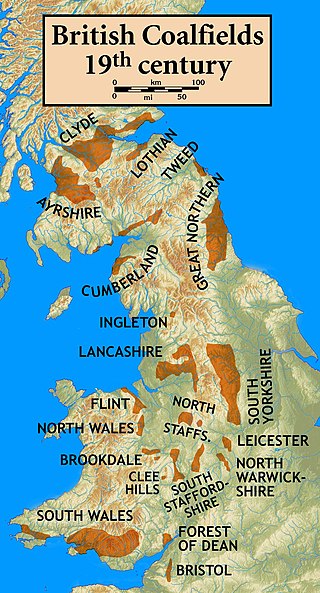

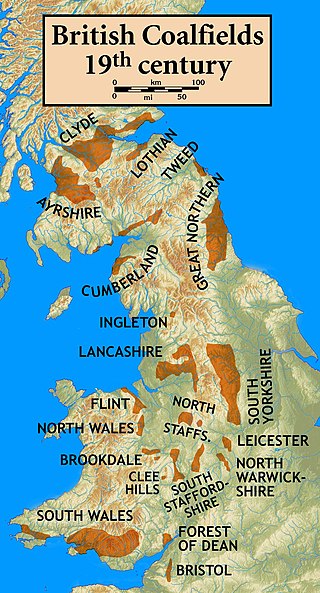

The South Yorkshire Coalfield is so named from its position within Yorkshire. It covers most of South Yorkshire, West Yorkshire and a small part of North Yorkshire. The exposed coalfield outcrops in the Pennine foothills and dips under Permian rocks in the east. Its most famous coal seam is the Barnsley Bed. Coal has been mined from shallow seams and outcrops since medieval times and possibly earlier.

The Lancashire Coalfield in North West England was an important British coalfield. Its coal seams were formed from the vegetation of tropical swampy forests in the Carboniferous period over 300 million years ago.

The Ingleton Coalfield is in North Yorkshire, close to its border with Lancashire in north-west England. Isolated from other coal-producing areas, it is one of the smallest coalfields in Great Britain.

The Astley and Tyldesley Collieries Company formed in 1900 owned coal mines on the Lancashire Coalfield south of the railway in Astley and Tyldesley, then in the historic county of Lancashire, England. The company became part of Manchester Collieries in 1929 and some of its collieries were nationalised in 1947.

Bedford Colliery, also known as Wood End Pit, was a coal mine on the Manchester Coalfield in Bedford, Leigh, Lancashire, England. The colliery was owned by John Speakman, who started sinking two shafts on land at Wood End Farm in the northeast part of Bedford, south of the London and North Western Railway's Tyldesley Loopline in about 1874. Speakman's father owned Priestners, Bankfield, and Broadoak collieries in Westleigh. Bedford Colliery remained in the possession of the Speakman family until it was amalgamated with Manchester Collieries in 1929.

The Manchester Coalfield is part of the South Lancashire Coalfield, the coal seams of which were laid down in the Carboniferous Period. Some easily accessible seams were worked on a small scale from the Middle Ages, and extensively from the beginning of the Industrial Revolution in the early 19th century until the last quarter of the 20th century. The Coal Measures lie above a bed of Millstone Grit and are interspersed with sandstones, mudstones, shales, and fireclays. The Lower Coal Measures occupy the high ground of the West Pennine Moors above Bolton and are not worked in the Manchester Coalfield. The most productive of the coal measures are the lower two thirds of the Middle Coal Measures where coal is mined from seams between the Worsley Four Foot and Arley mines. The deepest and most productive collieries were to the south of the coalfield. The coalfield is affected by the northwest to southeast aligned Pendleton Fault along the Irwell Valley and the Rossendale Valley anticline. The Coal Measures generally dip towards the south and west. Numerous other smaller faults affect the coalfield. The Upper Coal Measures are not worked in the Manchester Coalfield.

Fletcher, Burrows and Company was a coal mining company that owned collieries and cotton mills in Atherton, Greater Manchester, England. Gibfield, Howe Bridge and Chanters collieries exploited the coal mines (seams) of the middle coal measures in the Manchester Coalfield. The Fletchers built company housing at Hindsford and a model village at Howe Bridge which included pithead baths and a social club for its workers. The company became part of Manchester Collieries in 1929. The collieries were nationalised in 1947 becoming part of the National Coal Board.

Bridgewater Collieries originated from the coal mines on the Manchester Coalfield in Worsley in the historic county of Lancashire owned by Francis Egerton, 3rd Duke of Bridgewater in the second half of the 18th century. After the Duke's death in 1803 his estate was managed by the Bridgewater Trustees until the 3rd Earl of Ellesmere inherited the estates in 1903. Bridgewater Collieries was formed in 1921 by the 4th Earl. The company merged with other prominent mining companies to form Manchester Collieries in 1929.

The Clifton and Kersley Coal Company or Clifton and Kearsley Coal Company was a coal mining company that operated in Clifton and Kearsley on the south side of the Irwell Valley, then in the historic county of Lancashire, England. Its collieries exploited the coal mines (seams) of the middle coal measures in the Manchester Coalfield. Pits had been sunk in the 1730s and in the 1740s John Heathcote who owned the pits employed Matthew Fletcher. The Fletchers had extensive interests in coal mining in the area and, by the 1750s, Fletcher owned the collieries.

Astley Green Colliery was a coal mine in Astley, Greater Manchester, then in the historic county of Lancashire, England. It was the last colliery to be sunk in Astley. Sinking commenced in 1908 by the Pilkington Colliery Company, a subsidiary of the Clifton and Kersley Coal Company, at the southern edge of the Manchester Coalfield, working the Middle Coal Measures where they dipped under the Permian age rocks under Chat Moss. The colliery was north of the Bridgewater Canal. In 1929 it became part of Manchester Collieries, and in 1947 was nationalised and integrated into the National Coal Board. It closed in 1970, and is now Astley Green Colliery Museum.

Chanters Colliery was a coal mine which was part of the Fletcher, Burrows and Company's collieries at Hindsford in Atherton, Greater Manchester, then in the historic county of Lancashire, England.

Nook Colliery was a coal mine operating on the Manchester Coalfield after 1866 in Tyldesley, Greater Manchester, then in the historic county of Lancashire, England.

Cleworth Hall Colliery was a coal mine operating on the Manchester Coalfield after 1874 in Tyldesley, Greater Manchester, then in the historic county of Lancashire, England.

Bradford Colliery was a coal mine in Bradford, Manchester, England. Although part of the Manchester Coalfield, the seams of the Bradford Coalfield correspond more closely to those of the Oldham Coalfield. The Bradford Coalfield is crossed by a number of fault lines, principally the Bradford Fault, which was reactivated by mining activity in the mid-1960s.

The Burnley Coalfield is the most northerly portion of the Lancashire Coalfield. Surrounding Burnley, Nelson, Blackburn and Accrington, it is separated from the larger southern part by an area of Millstone Grit that forms the Rossendale anticline. Occupying a syncline, it stretches from Blackburn past Colne to the Yorkshire border where its eastern flank is the Pennine anticline.

Bank Hall Colliery was a coal mine on the Burnley Coalfield in Burnley, Lancashire near the Leeds and Liverpool Canal. Sunk in the late 1860s, it was the town's largest and deepest pit and had a life of more than 100 years.

References

Notes

Footnotes

- ↑ Fanning 2001, p. 21.

- ↑ Fanning 2001, p. 8.

- ↑ Fanning 2001, p. 11.

- ↑ Fanning 2001, p. 9.

- ↑ Fanning 2001, p. 22.

- ↑ Greater Manchester (including: Wigan, Bolton, Salford, Trafford, Bury, Rochdale, Stockport, Manchester, Tameside and Oldham), Natural England, archived from the original on 27 March 2012, retrieved 2 October 2012

- ↑ Ashmore 1982, p. 118

- ↑ Fanning 2001, p. 12.

- ↑ Chamber Colliery Co, Grace's Guide, retrieved 17 September 2011

- ↑ Fanning 2001, p. 7.

- ↑ Ashmore 1969, p. 88

- ↑ Davies 2010, p. 169

- ↑ Ashmore 1969, p. 294

- ↑ Ashmore 1969, p. 295

- ↑ Ashmore 1982, p. 120

Bibliography

- Ashmore, Owen (1969), Industrial Archaeology of Lancashire , David & Charles, ISBN 07153-4339-4

- Ashmore, Owen (1982), The Industrial archaeology of North-west England, Manchester University Press, ISBN 0-7190-0820-4

- Davies, Alan (2010), Coal Mining in Lancashire & Cheshire, Amberley, ISBN 978-1-84868-488-1

- Fanning, Gerry (2001), Oldham Coal, Northern Mine Research Society, ISBN 0-901450-54-5