In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

Logistics is the part of supply chain management that deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the point of consumption according to the needs of customers. Logistics management is a component that holds the supply chain together. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

Inventory or stock refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

A supply chain is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods in distribution channels within the supply chain in the most efficient manner.

Vendor-managed inventory (VMI) is an inventory management practice in which a supplier of goods, usually the manufacturer, is responsible for optimizing the inventory held by a distributor.

Service management in the manufacturing context, is integrated into supply chain management as the intersection between the actual sales and the customer point of view. The aim of high-performance service management is to optimize the service-intensive supply chains, which are usually more complex than the typical finished-goods supply chain. Most service-intensive supply chains require larger inventories and tighter integration with field service and third parties. They also must accommodate inconsistent and uncertain demand by establishing more advanced information and product flows. Moreover, all processes must be coordinated across numerous service locations with large numbers of parts and multiple levels in the supply chain.

The beer distribution game is an educational game that is used to experience typical coordination problems of a supply chain process. It reflects a role-play simulation where several participants play with each other. The game represents a supply chain with a non-coordinated process where problems arise due to lack of information sharing. This game outlines the importance of information sharing, supply chain management and collaboration throughout a supply chain process. Due to lack of information, suppliers, manufacturers, sales people and customers often have an incomplete understanding of what the real demand of an order is. The most interesting part of the game is that each group has no control over another part of the supply chain. Therefore, each group has only significant control over their own part of the supply chain. Each group can highly influence the entire supply chain by ordering too much or too little which can lead to a bullwhip effect. Therefore, the order taking of a group also highly depends on decisions of the other groups.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

Demand management is a planning methodology used to forecast, plan for and manage the demand for products and services. This can be at macro-levels as in economics and at micro-levels within individual organizations. For example, at macro-levels, a government may influence interest rates to regulate financial demand. At the micro-level, a cellular service provider may provide free night and weekend use to reduce demand during peak hours.

Inventory control or stock control can be broadly defined as "the activity of checking a shop's stock". It is the process of ensuring that the right amount of supply is available within a business. However, a more focused definition takes into account the more science-based, methodical practice of not only verifying a business's inventory but also maximising the amount of profit from the least amount of inventory investment without affecting customer satisfaction. Other facets of inventory control include forecasting future demand, supply chain management, production control, financial flexibility, purchasing data, loss prevention and turnover, and customer satisfaction.

The business terms push and pull originated in logistics and supply chain management, but are also widely used in marketing and in the hotel distribution business.

In business, a demand chain is the understanding and management of customer demand, in contrast to a supply chain. Madhani suggests that the demand chain "comprises all the demand processes necessary to understand, create, and stimulate customer demand". Cranfield School of Management academic Martin Christopher has suggested that "ideally the supply chain should become a demand chain", explaining that ideally all product logistics and processing should occur "in response to a known customer requirement".

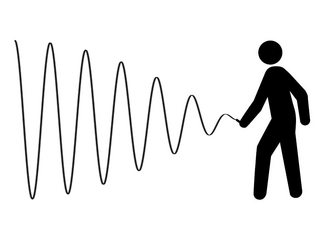

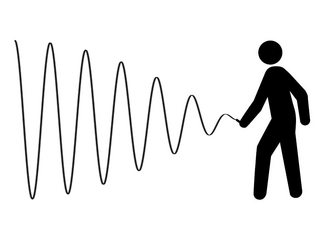

The bullwhip effect is a supply chain phenomenon where orders to suppliers tend to have a larger variability than sales to buyers, which results in an amplified demand variability upstream. In part, this results in increasing swings in inventory in response to shifts in consumer demand as one moves further up the supply chain. The concept first appeared in Jay Forrester's Industrial Dynamics (1961) and thus it is also known as the Forrester effect. It has been described as "the observed propensity for material orders to be more variable than demand signals and for this variability to increase the further upstream a company is in a supply chain". Research at Stanford University helped incorporate the concept into supply chain vernacular using a story about Volvo. Suffering a glut in green cars, sales and marketing developed a program to sell the excess inventory. While successful in generating the desired market pull, manufacturing did not know about the promotional plans. Instead, they read the increase in sales as an indication of growing demand for green cars and ramped up production.

Demand-chain management (DCM) is the management of relationships between suppliers and customers to deliver the best value to the customer at the least cost to the demand chain as a whole. Demand-chain management is similar to supply-chain management but with special regard to the customers.

Collaborative planning, forecasting, and replenishment (CPFR) is an approach to the supply chain process which focuses on joint practices. This is done through cooperative management of inventory through joint visibility and replenishment of products throughout the supply chain. Information shared between suppliers and retailers aids in satisfying customer demands through a system of shared information. This allows for continuous updating of inventory and upcoming requirements, making the end-to-end supply chain process more efficient. Efficiency is created through the decrease expenditures for merchandising, inventory, logistics, and transportation across all trading partners.

Build to Order is a production approach where products are not built until a confirmed order for products is received. Thus, the end consumer determines the time and number of produced products. The ordered product is customized, meeting the design requirements of an individual, organization or business. Such production orders can be generated manually, or through inventory/production management programs. BTO is the oldest style of order fulfillment and is the most appropriate approach used for highly customized or low volume products. Industries with expensive inventory use this production approach. Moreover, "Made to order" products are common in the food service industry, such as at restaurants.

The Supply Chain Operations Reference (SCOR) model is a process reference model originally developed and endorsed by the Supply Chain Council, now a part of ASCM, as the cross-industry, standard diagnostic tool for supply chain management. The SCOR model describes the business activities associated with satisfying a customer's demand, which include plan, source, make, deliver, return, and enable. Use of the model includes analyzing the current state of a company's processes and goals, quantifying operational performance, and comparing company performance to benchmark data. SCOR has developed a set of metrics for supply chain performance, and ASCM members have formed industry groups to collect best practices information that companies can use to elevate their supply chain models.

Production leveling, also known as production smoothing or – by its Japanese original term – heijunka (平準化), is a technique for reducing the mura (unevenness) which in turn reduces muda (waste). It was vital to the development of production efficiency in the Toyota Production System and lean manufacturing. The goal is to produce intermediate goods at a constant rate so that further processing may also be carried out at a constant and predictable rate.

Merge-in-transit (MIT) is a distribution method in which several shipments from suppliers originating at different locations are consolidated into one final customer delivery. This removes the need for distribution warehouses in the supply chain, allowing customers to receive complete deliveries for their orders. Under a merge-in-transit system, merge points replace distribution warehouse. In today's global market, merge-in-transit is progressively being used in telecommunications and electronic industries. These industries are usually dynamic and flexible, in which products have been developed and changed rapidly.

Operations management for services has the functional responsibility for producing the services of an organization and providing them directly to its customers. It specifically deals with decisions required by operations managers for simultaneous production and consumption of an intangible product. These decisions concern the process, people, information and the system that produces and delivers the service. It differs from operations management in general, since the processes of service organizations differ from those of manufacturing organizations.