Types of plasmas used for surface activation

Many types of plasmas can be used for surface activation. However, due to economic reasons, atmospheric pressure plasmas found most applications. They include arc discharge, corona discharge, dielectric barrier discharge and its variation piezoelectric direct discharge.

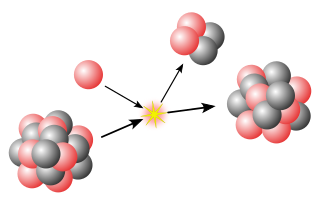

Arc discharge

Arc discharges at atmospheric pressure are self-sustained DC electric discharges with large electric currents, typically higher than 1 A, in some cases reaching up to 100.000 A, and relatively low voltages, typically of the order of 10 – 100 V. Due to high collision frequencies of plasma species, atmospheric pressure arcs are in thermal equilibrium having temperatures of the order of 6.000 – 12.000 °C. Most of the arc volume is electrically neutral except for thin anode and cathode layers where strong electric fields are present. These typically collision-less layers have voltage drops of about 10 – 20 V. Ions, which are produced within the cathode layer, accelerate in this voltage and impact the cathode surface with high energies. This process heats the cathode stimulating thermal electron emission, which sustains the high discharge currents. On the cathode surface the electric currents concentrate at fast moving spots with sizes of 1 – 100 μm. Within these spots, the cathode material reaches local temperatures of 3000 °C, leading to its evaporation and a slow cathode erosion. [2]

Pulsed atmospheric arc technology improves the arc stability at low electric currents, maximizes the discharge volume, and together with it the production of reactive species for plasma activation, while at the same time reducing the size of the driving high voltage electronics. These factors make it economically very attractive for industrial applications.

There are two ways of using electric arcs for surface activation: non-transferred and transferred electric arcs. In the non-transferred technique, both electrodes are part of the plasma source. One of them also acts as a gas nozzle producing a stream of plasma. After the plasma stream leaves the arc region, the ions recombine quickly, leaving the hot gas having high concentrations of chemically active hydrogen, nitrogen and oxygen atoms and compounds, which is also called remote plasma. The temperature of this gas stream is of the order of 200 – 500 °C. The gas is very reactive allowing high surface treatment speeds when only a short-time contact with the substrate is sufficient to achieve the activation effect. This gas can activate all materials, including temperature-sensitive plastics. Moreover, it is electrically neutral and free from electric potentials, which is important for activation of sensitive electronics.

In the transferred technique of using the electric arcs, the substrate itself plays the role of the cathode. In this case, the substrate is subject not only to the reactive chemical species, but also to their ions with energies of up to 10 – 20 eV, to high temperatures reaching within the cathode spots 3000 °C, and to UV light. These additional factors lead to even greater activation speeds. This treatment method is suitable for conductive substrates such as metals. It reduces metal oxides by their reactions with hydrogen species and leaves the surface free from organic contaminants. Moreover, the fast moving multiple cathode spots create a microstructure on the substrate improving mechanical binding of the adhesive.

Corona discharge

Corona discharges appear at atmospheric pressures in strongly non-uniform electric fields. Sharp edges of high voltage electrodes produce such fields in their vicinity. When the field in the rest space is negligible – this happens at large distances to the electric grounds – the corona discharge can be ignited. Otherwise, the high voltage electrodes may spark to the ground.

Depending on the polarity of the high voltage electrode one distinguishes negative corona, formed around the cathode, and positive corona, formed around the anode. Negative corona is similar to the Townsend discharge, where the electrons, emitted by the cathode, accelerate in the electric field, ionize the gas in collisions with its atoms and molecules releasing more electrons, and thus creating an avalanche. Secondary processes include electron emission from the cathode and photoionization within the gas volume. Negative corona creates a uniform plasma glowing around the sharp edges of the electrodes. On the other hand, electrons initiating the avalanches in the positive corona are produced by the photoionization of the gas, surrounding the high voltage anode. The photons are emitted in the more active region of the anode vicinity. Then the electron avalanches propagate towards the anode. The plasma of the positive corona consists out of many constantly moving filaments.

Corona discharges produce electric currents of the order of 1 – 100 μA at high voltages of the order of several kV. These currents and the corresponding discharge power are low comparing to the currents and the power of the arc and the dielectric barrier discharges. However, the advantage of the corona discharge is simplicity of the DC high voltage electronics. While electric sparks limit the high voltage, and thus the corona power, the latter can be further increased with a help of pulse-periodic high voltages. However, this complicates the high voltage system. [3]

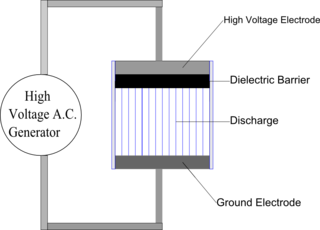

Dielectric barrier discharge

Dielectric barrier discharge occurs between two electrodes separated by a dielectric. Due to the presence of the dielectric barrier, such plasma sources operate only with sine-wave or pulsed high voltages. The physical principles of the discharge do not limit the operating frequency range. The typical frequencies of commonly used solid-state high voltage supplies are 0.05 – 500 kHz. The voltage amplitudes of the order of 5 – 20 kV produce electric currents in the range of 10 – 100 mA. The power of the dielectric barrier discharge is significantly higher than that of the corona discharge, but smaller comparing to the arc discharge. The discharge generally consists of multiple micro-discharges, although in some cases uniform discharges are created too. [3] To increase the uniformity and the discharge gap in the case of VBDB, a pre-ionization system can be used. [4]

Other types of DBD used for functionalization are plasma jets. [5] The processed area is smaller compared with the surface or volume DBD discharges. Micro plasma jets produced in capillary tubes with less than 1μm diameter tip are ultrafine atmospheric pressure plasma jets and proved to be great tools in micro-size processing and functionalization of materials such as carbon nanotubes [6] or polymers. [7]

Piezoelectric direct discharge

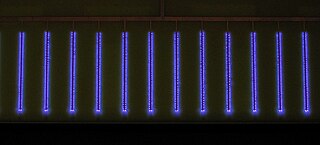

Piezoelectric direct discharge can be considered as a special technical realization of the dielectric barrier discharge, which combines the alternating current high voltage generator, high voltage electrode and the dielectric barrier into a single element. Namely, the high voltage is generated with a piezo-transformer, the secondary circuit of which acts also as the high voltage electrode. [8] [9] Since the piezoelectric material of the transformer, such as lead zirconate titanate, is often a dielectric, the produced electric discharge resembles properties of the dielectric barrier discharge. In addition, when operated in far from the electric ground, it also produces corona discharges on the sharp edges of the piezo-transformer.

Due to the unique construction principles, the piezoelectric barrier discharge is the economic and compact source of the dielectric barrier and corona plasmas. Although its power is limited to about 10 W per unit, the low costs and small sizes of the units allow construction of large arrays optimized for particular applications.

Further types of plasmas

Plasmas suitable for surface activation were also created using inductive heating with RF and microwave frequencies, spark discharges, resistive barrier discharges [10] and various types of micro-discharges.