A barometer is a scientific instrument that is used to measure air pressure in a certain environment. Pressure tendency can forecast short term changes in the weather. Many measurements of air pressure are used within surface weather analysis to help find surface troughs, pressure systems and frontal boundaries.

In science and engineering the study of high pressure examines its effects on materials and the design and construction of devices, such as a diamond anvil cell, which can create high pressure. High pressure usually means pressures of thousands (kilobars) or millions (megabars) of times atmospheric pressure.

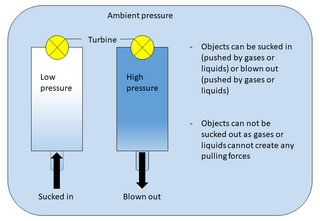

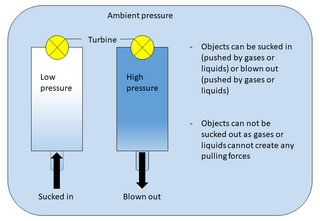

Suction is the day-to-day term for forces experienced by objects that are exposed to the movement of gases or liquids moving along a pressure gradient. Contrary to popular belief, however, the forces acting in this case do not originate from the lower pressure side, but from the side of the higher pressure.

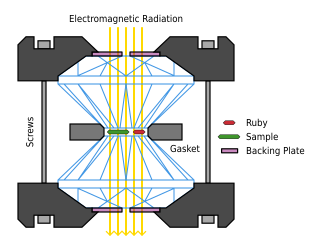

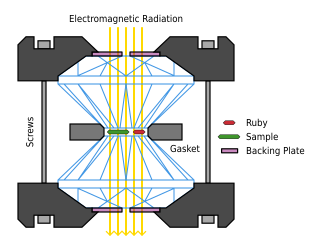

A diamond anvil cell (DAC) is a high-pressure device used in geology, engineering, and materials science experiments. It enables the compression of a small (sub-millimeter-sized) piece of material to extreme pressures, typically up to around 100–200 gigapascals, although it is possible to achieve pressures up to 770 gigapascals.

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word manifold comes from the Old English word manigfeald and refers to the folding together of multiple inputs and outputs.

Manifold vacuum, or engine vacuum in an internal combustion engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere.

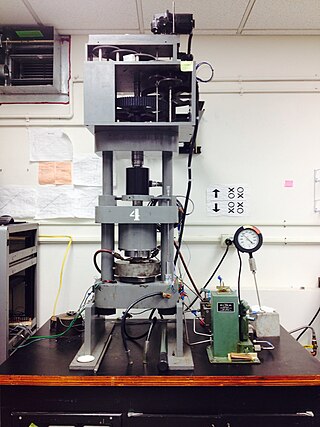

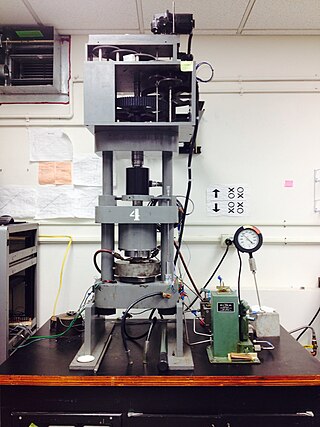

A multi-anvil press, or anvil press is a type of device related to a machine press that is used to create extraordinarily high pressures within a small volume.

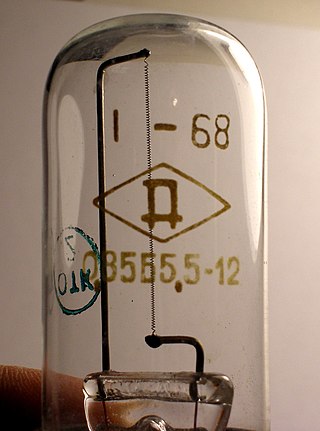

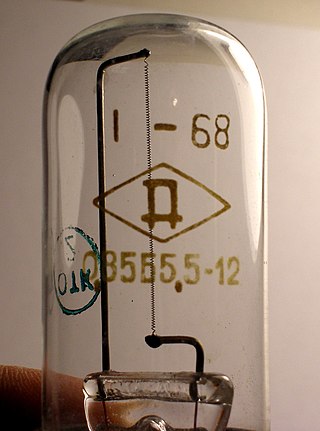

Vacuum engineering is the field of engineering that deals with the practical use of vacuum in industrial and scientific applications. Vacuum may improve the productivity and performance of processes otherwise carried out at normal air pressure, or may make possible processes that could not be done in the presence of air. Vacuum engineering techniques are widely applied in materials processing such as drying or filtering, chemical processing, application of metal coatings to objects, manufacture of electron devices and incandescent lamps, and in scientific research.

A Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier engines designed by James Watt. The engines were also used for powering man engines to assist the underground miners' journeys to and from their working levels, for winching materials into and out of the mine, and for powering on-site ore stamping machinery.

In a spark ignition internal combustion engine, ignition timing is the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke.

Engine efficiency of thermal engines is the relationship between the total energy contained in the fuel, and the amount of energy used to perform useful work. There are two classifications of thermal engines-

- Internal combustion and

- External combustion engines.

The first recorded rudimentary steam engine was the aeolipile mentioned by Vitruvius between 30 and 15 BC and, described by Heron of Alexandria in 1st-century Roman Egypt. Several steam-powered devices were later experimented with or proposed, such as Taqi al-Din's steam jack, a steam turbine in 16th-century Ottoman Egypt, and Thomas Savery's steam pump in 17th-century England. In 1712, Thomas Newcomen's atmospheric engine became the first commercially successful engine using the principle of the piston and cylinder, which was the fundamental type of steam engine used until the early 20th century. The steam engine was used to pump water out of coal mines.

Mineral physics is the science of materials that compose the interior of planets, particularly the Earth. It overlaps with petrophysics, which focuses on whole-rock properties. It provides information that allows interpretation of surface measurements of seismic waves, gravity anomalies, geomagnetic fields and electromagnetic fields in terms of properties in the deep interior of the Earth. This information can be used to provide insights into plate tectonics, mantle convection, the geodynamo and related phenomena.

A booster pump is a machine which increases the pressure of a fluid. It may be used with liquids or gases, and the construction details vary depending on the fluid. A gas booster is similar to a gas compressor, but generally a simpler mechanism which often has only a single stage of compression, and is used to increase pressure of a gas already above ambient pressure. Two-stage boosters are also made. Boosters may be used for increasing gas pressure, transferring high pressure gas, charging gas cylinders and scavenging.

Iron–hydrogen alloy, also known as iron hydride, is an alloy of iron and hydrogen and other elements. Because of its lability when removed from a hydrogen atmosphere, it has no uses as a structural material.

Griggs apparatus, also referred to as a Griggs rig, is a modified piston cylinder high pressure apparatus used to create an environment of high pressure, high temperature and to impart a deviatoric stress on a sample of material. It was conceived in the 1960s.

The D-DIA or deformation-DIA is an apparatus used for high pressure and high temperature deformation experiments. The advantage of this apparatus is the ability to apply pressures up to approximately 15 GPa while independently creating uniaxial strains up to 50%.

The piston-cylinder apparatus is a solid media device, used in Geosciences and Material Sciences, for generating simultaneously high pressure and temperature. Modifications of the normal set-up can push these limits to even higher pressures and temperatures. A particular type of piston-cylinder, called Griggs apparatus, is also able to add a deviatoric stress on the sample.

Disodium helide (Na2He) is a compound of helium and sodium that is stable at high pressures above 113 gigapascals (1,130,000 bar). It was first predicted using the USPEX crystal structure prediction algorithm and then synthesised in 2016.

Charles E. Weir was a chemist and physicist known for being one of the four co-inventors of the diamond anvil cell at the National Bureau of Standards in the late 1950s, with Alvin Van Valkenburg, Ellis Lippincott and Elmer Bunting. Weir had the principal role in designing the first diamond anvil cell, and built it by hand using the machining tools available in his lab. The original device was first described in a paper on high-pressure infrared absorption measurements of calcium carbonate. Later, Weir collaborated in the development of diamond anvil cells for powder and single-crystal X-ray diffraction.