The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is called a compression-ignition engine. This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine or a gas engine.

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines.

Wilhelm Maybach was an early German engine designer and industrialist. During the 1890s he was hailed in France, then the world centre for car production, as the "King of Designers".

A four-strokeengine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

- Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing a partial vacuum in the cylinder through its downward motion.

- Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are closed during this stage.

- Combustion: Also known as power or ignition. This is the start of the second revolution of the four stroke cycle. At this point the crankshaft has completed a full 360 degree revolution. While the piston is at T.D.C. the compressed air-fuel mixture is ignited by a spark plug or by heat generated by high compression, forcefully returning the piston to B.D.C. This stroke produces mechanical work from the engine to turn the crankshaft.

- Exhaust: Also known as outlet. During the exhaust stroke, the piston, once again, returns from B.D.C. to T.D.C. while the exhaust valve is open. This action expels the spent air-fuel mixture through the exhaust port.

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

MTU Friedrichshafen GmbH is a German manufacturer of commercial internal combustion engines founded by Wilhelm Maybach and his son Karl Maybach in 1909. Wilhelm Maybach was the technical director of Daimler-Motoren-Gesellschaft (DMG), a predecessor company of the German multinational automotive corporation Daimler AG, until he left in 1907. On 23 March 1909, he founded the new company, Luftfahrzeug-Motorenbau GmbH, with his son Karl Maybach as director. A few years later the company was renamed to Maybach-Motorenbau GmbH, which originally developed and manufactured diesel and petrol engines for Zeppelins, and then railcars. The Maybach Mb.IVa was used in aircraft and airships of World War I.

The Daimler-Benz DB 601 was a German aircraft engine that was built during World War II. It was a liquid-cooled inverted V12, and powered the Messerschmitt Bf 109, Messerschmitt Bf 110, and many others. Approximately 19,000 601's were produced before it was replaced by the improved Daimler-Benz DB 605 in 1942.

Indirect injection in an internal combustion engine is fuel injection where fuel is not directly injected into the combustion chamber.

Deutz AG is a German internal combustion engine manufacturer, based in Porz, Cologne, Germany.

Common rail direct fuel injection is a direct fuel injection system built around a high-pressure fuel rail feeding solenoid valves, as opposed to a low-pressure fuel pump feeding unit injectors. High-pressure injection delivers power and fuel consumption benefits over earlier lower pressure fuel injection, by injecting fuel as a larger number of smaller droplets, giving a much higher ratio of surface area to volume. This provides improved vaporization from the surface of the fuel droplets, and so more efficient combining of atmospheric oxygen with vaporized fuel delivering more complete combustion.

Gasoline direct injection (GDI), also known as petrol direct injection (PDI), is a mixture formation system for internal combustion engines that run on gasoline (petrol), where fuel is injected into the combustion chamber. This is distinct from manifold injection systems, which inject fuel into the intake manifold.

The hot-bulb engine, also known as a semi-diesel, is a type of internal combustion engine in which fuel ignites by coming in contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine.

Rolls-Royce Power Systems AG is a German company owned by Rolls-Royce Holdings with holdings in engine manufacturing brands and facilities. The company previously traded, from 2006 to 2014, as Tognum AG. Prior to 2006, the core company – MTU Friedrichshafen GmbH – was a constituent of DaimlerChrysler Powersystems Off-Highway.

A unit injector (UI) is a high-pressure integrated direct fuel injection system for diesel engines, combining the injector nozzle and the injection pump in a single component. The plunger pump used is usually driven by a shared camshaft. In a unit injector, the device is typically lubricated and cooled by the fuel itself.

Woodward L'Orange GmbH is a German engineering manufacturing company headquartered in Stuttgart. It is one of the leading manufacturers of injection systems for large diesel engines worldwide. It developed and produced the first common-rail system for large diesel engines. Woodward L'Orange is a supplier to engine builders and has been part of Woodward since 2018. Previously the L'Orange GmbH belonged to the Rolls-Royce Power Systems AG.

Air-blast injection is a historical direct injection system for Diesel engines. Unlike modern designs, air-blast injected Diesel engines do not have an injection pump. A simple low-pressure fuel-feed-pump is used instead to supply the injection nozzle with fuel. At injection, a blast of compressed air presses the fuel into the combustion chamber, hence the name air-blast injection. The compressed air comes from compressed-air tanks which feed the injection nozzle. A large crankshaft-driven compressor is used to re-fill these tanks; the size of the compressor and the low rotational frequency of the engine's crankshaft means that air-blast injected Diesel engines are huge in size and mass, this, combined with the problem that air-blast injection does not allow for quick load alteration makes it only suitable for stationary applications and watercraft. Before the invention of precombustion chamber injection, air-blast injection was the only way a properly working internal air fuel mixture system could be built, required for a Diesel engine. During the 1920s, air-blast injection was rendered obsolete by superior injection system designs that allowed much smaller but more powerful engines. Rudolf Diesel was granted a patent on air-blast injection in November 1893.

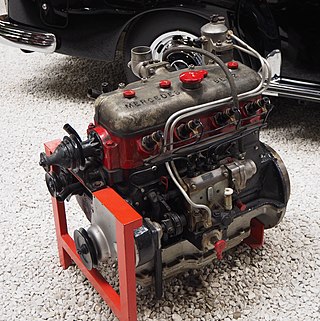

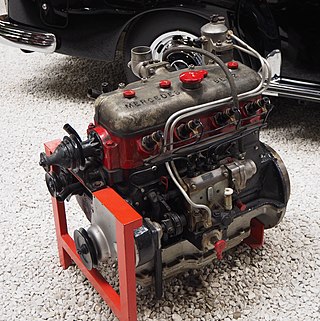

The Mercedes-Benz OM636 is a diesel engine that was produced by Daimler-Benz from 1948 until 1990. Being the successor to the OM138, the OM636 has been used both as a passenger car engine and as an industrial engine. It saw its first use in the Boehringer Unimog in 1948, prior to its official introduction in the 1949 Mercedes-Benz W136. Throughout the 1950s, the OM636 was widely used in the Mercedes-Benz W120. In 1958, it was succeeded by the OM621 passenger car engine. However, after the introduction of the OM621, the OM636 was kept in production for industrial vehicles such as small lorries, boats, and combine harvesters, until 1990.

The MWM AKD 112 Z is an air-cooled two-cylinder inline diesel engine produced by MWM from 1955 – 1960. One, three and four cylinder variants of the same engine family were also produced by MWM.

The Mercedes-Benz OM 138 is a diesel engine manufactured by Daimler-Benz. In total, 5,719 units were produced between 1935 and 1940. It was the first diesel engine especially developed and made for a passenger car. The first vehicle powered by the OM 138 was the Mercedes-Benz W 138. The light Mercedes-Benz trucks L 1100 and L 1500 as well as the bus O 1500 were also offered with the OM 138 as an alternative to the standard Otto engine.

Hans Nibel was a German mechanical engineer.