A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing and to transform many other materials.

Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitary ware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Flint, occasionally flintstone, is a sedimentary cryptocrystalline form of the mineral quartz, categorized as the variety of chert that occurs in chalk or marly limestone. Historically, flint was widely used to make stone tools and start fires.

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The nanoparticles in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece.

Tiles are usually thin, square or rectangular coverings manufactured from hard-wearing material such as ceramic, stone, metal, baked clay, or even glass. They are generally fixed in place in an array to cover roofs, floors, walls, edges, or other objects such as tabletops. Alternatively, tile can sometimes refer to similar units made from lightweight materials such as perlite, wood, and mineral wool, typically used for wall and ceiling applications. In another sense, a tile is a construction tile or similar object, such as rectangular counters used in playing games. The word is derived from the French word tuile, which is, in turn, from the Latin word tegula, meaning a roof tile composed of fired clay.

Pottery and porcelain is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Types have included earthenware, pottery, stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics hold within its artistic tradition, owing to the enduring popularity of the tea ceremony.

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes are sometimes used to reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product. This occurs especially often with small metal parts, like gears for small machines. Some porous products, allowing liquid or gas to permeate them, are produced in this way. They are also used when melting a material is impractical, due to it having a high melting point, or an alloy of two mutually insoluble materials, such as a mixture of copper and graphite.

A vase is an open container. It can be made from a number of materials, such as ceramics, glass, non-rusting metals, such as aluminium, brass, bronze, or stainless steel. Even wood has been used to make vases, either by using tree species that naturally resist rot, such as teak, or by applying a protective coating to conventional wood or plastic. Vases are often decorated, and they are often used to hold cut flowers. Vases come in different sizes to support whatever flower is being held or kept in place.

In pottery, a potter's wheel is a machine used in the shaping of clay into round ceramic ware. The wheel may also be used during the process of trimming excess clay from leather-hard dried ware that is stiff but malleable, and for applying incised decoration or rings of colour. Use of the potter's wheel became widespread throughout the Old World but was unknown in the Pre-Columbian New World, where pottery was handmade by methods that included coiling and beating.

Slip casting, or slipcasting, is a ceramic forming technique, and is widely used in industry and by craft potters to make ceramic forms. This technique typically used to form complicated shapes like figurative ceramics that would be difficult to be reproduced by hand or other forming techniques. The technique involves a clay body slip, usually prepared in a blunger, being poured into plaster moulds and allowed to form a layer, the cast, on the internal walls of the mould.

Ceramic forming techniques are ways of forming ceramics, which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts. Pottery techniques include the potter's wheel, slip casting and many others.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

In metallurgy, a ladle is a bucket-shaped container or vessel used to transport and pour out molten metals. Ladles are often used in foundries and range in size from small hand-carried vessels that resemble a kitchen ladle and hold 20 kilograms (44 lb) to large steelmill ladles that hold up to 300 tonnes. Many non-ferrous foundries also use ceramic crucibles for transporting and pouring molten metal and will also refer to these as ladles.

Ceramic water filters (CWF) are an inexpensive and effective type of water filter that rely on the small pore size of ceramic material to filter dirt, debris, and bacteria out of water. This makes them ideal for use in developing countries, and portable ceramic filters are commonly used in backpacking.

This is a list of pottery and ceramic terms.

A mechanical powder press is a machine press designed to compress powders, commonly used in the production of technical ceramics.

Mississippian culture pottery is the ceramic tradition of the Mississippian culture found as artifacts in archaeological sites in the American Midwest and Southeast. It is often characterized by the adoption and use of riverine shell-tempering agents in the clay paste. Shell tempering is one of the hallmarks of Mississippian cultural practices. Analysis of local differences in materials, techniques, forms, and designs is a primary means for archaeologists to learn about the lifeways, religious practices, trade, and interaction among Mississippian peoples. The value of this pottery on the illegal antiquities market has led to extensive looting of sites.

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.

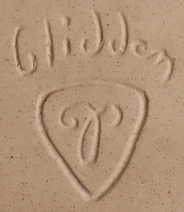

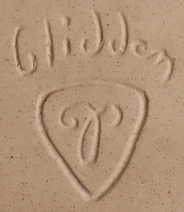

Glidden Pottery produced unique stoneware, dinnerware and artware in Alfred, New York from 1940 to 1957. The company was established by Glidden Parker, who had studied ceramics at the New York State College of Ceramics at Alfred University. Glidden Pottery's mid-century designs combined molded stoneware forms with hand-painted decoration. The New Yorker magazine described Glidden Pottery as "distinguished by a mat surface, soft color combinations, and, in general, well-thought-out forms that one won't see duplicated in other wares". Gliddenware was sold in leading department stores across the country. Examples of Glidden Pottery can occasionally be seen in television programs from the era, such as I Love Lucy.