Microfluidics refers to a system that manipulates a small amount of fluids using small channels with sizes ten to hundreds micrometres. It is a multidisciplinary field that involves molecular analysis, molecular biology, and microelectronics. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies.

Electrophysiology is the branch of physiology that studies the electrical properties of biological cells and tissues. It involves measurements of voltage changes or electric current or manipulations on a wide variety of scales from single ion channel proteins to whole organs like the heart. In neuroscience, it includes measurements of the electrical activity of neurons, and, in particular, action potential activity. Recordings of large-scale electric signals from the nervous system, such as electroencephalography, may also be referred to as electrophysiological recordings. They are useful for electrodiagnosis and monitoring.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

Digital microfluidics (DMF) is a platform for lab-on-a-chip systems that is based upon the manipulation of microdroplets. Droplets are dispensed, moved, stored, mixed, reacted, or analyzed on a platform with a set of insulated electrodes. Digital microfluidics can be used together with analytical analysis procedures such as mass spectrometry, colorimetry, electrochemical, and electrochemiluminescense.

Particle image velocimetry (PIV) is an optical method of flow visualization used in education and research. It is used to obtain instantaneous velocity measurements and related properties in fluids. The fluid is seeded with tracer particles which, for sufficiently small particles, are assumed to faithfully follow the flow dynamics. The fluid with entrained particles is illuminated so that particles are visible. The motion of the seeding particles is used to calculate speed and direction of the flow being studied.

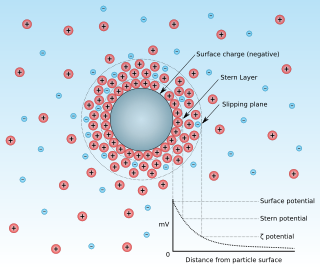

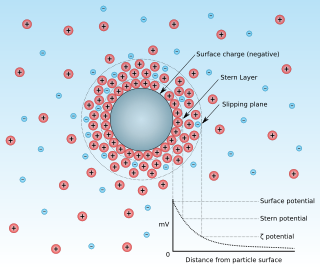

Zeta potential is the electrical potential at the slipping plane. This plane is the interface which separates mobile fluid from fluid that remains attached to the surface.

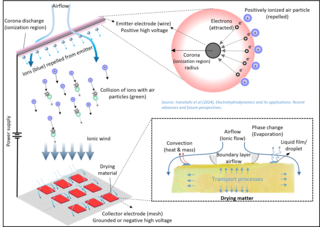

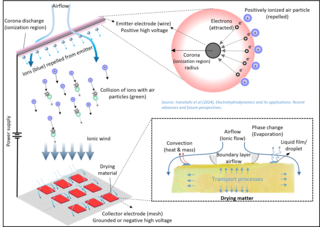

Electrohydrodynamics (EHD), also known as electro-fluid-dynamics (EFD) or electrokinetics, is the study of the dynamics of electrically charged fluids. Electrohydrodynamics (EHD) is a joint domain of electrodynamics and fluid dynamics mainly focused on the fluid motion induced by electric fields. EHD, in its simplest form, involves the application of an electric field to a fluid medium, resulting in fluid flow, form, or properties manipulation. These mechanisms arise from the interaction between the electric fields and charged particles or polarization effects within the fluid. The generation and movement of charge carriers (ions) in a fluid subjected to an electric field are the underlying physics of all EHD-based technologies.

An electrostatic precipitator (ESP) is a filterless device that removes fine particles, such as dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

A Coulter counter is an apparatus for counting and sizing particles suspended in electrolytes. The Coulter counter is the commercial term for the technique known as resistive pulse sensing or electrical zone sensing. The apparatus is based on the Coulter principle named after its inventor, Wallace H. Coulter.

A particle counter is used for monitoring and diagnosing particle contamination within specific clean media, including air, water and chemicals. Particle counters are used in a variety of applications in support of clean manufacturing practices, industries include: electronic components and assemblies, pharmaceutical drug products and medical devices, and industrial technologies such as oil and gas.

Nanofluidics is the study of the behavior, manipulation, and control of fluids that are confined to structures of nanometer characteristic dimensions. Fluids confined in these structures exhibit physical behaviors not observed in larger structures, such as those of micrometer dimensions and above, because the characteristic physical scaling lengths of the fluid, very closely coincide with the dimensions of the nanostructure itself.

Sedimentation potential occurs when dispersed particles move under the influence of either gravity or centrifugation or electricity in a medium. This motion disrupts the equilibrium symmetry of the particle's double layer. While the particle moves, the ions in the electric double layer lag behind due to the liquid flow. This causes a slight displacement between the surface charge and the electric charge of the diffuse layer. As a result, the moving particle creates a dipole moment. The sum of all of the dipoles generates an electric field which is called sedimentation potential. It can be measured with an open electrical circuit, which is also called sedimentation current.

Nanofluidic circuitry is a nanotechnology aiming for control of fluids in nanometer scale. Due to the effect of an electrical double layer within the fluid channel, the behavior of nanofluid is observed to be significantly different compared with its microfluidic counterparts. Its typical characteristic dimensions fall within the range of 1–100 nm. At least one dimension of the structure is in nanoscopic scale. Phenomena of fluids in nano-scale structure are discovered to be of different properties in electrochemistry and fluid dynamics.

A device generating linear or rotational motion using carbon nanotube(s) as the primary component, is termed a nanotube nanomotor. Nature already has some of the most efficient and powerful kinds of nanomotors. Some of these natural biological nanomotors have been re-engineered to serve desired purposes. However, such biological nanomotors are designed to work in specific environmental conditions. Laboratory-made nanotube nanomotors on the other hand are significantly more robust and can operate in diverse environments including varied frequency, temperature, mediums and chemical environments. The vast differences in the dominant forces and criteria between macroscale and micro/nanoscale offer new avenues to construct tailor-made nanomotors. The various beneficial properties of carbon nanotubes makes them the most attractive material to base such nanomotors on.

Izon Science Limited is a nanotechnology company that develops and sells nano-scale particle analysis and isolation tools. Their main instruments are based on principles of size exclusion chromatography and tunable resistive pulse sensing. Izon’s size-exclusion chromatography columns and related solutions are also used by diagnostics companies focused on developing extracellular vesicle biomarkers.

Microvasculature comprises the microvessels – venules and capillaries of the microcirculation, with a maximum average diameter of 0.3 millimeters. As the vessels decrease in size, they increase their surface-area-to-volume ratio. This allows surface properties to play a significant role in the function of the vessel.

In chemical analysis, capillary electrochromatography (CEC) is a chromatographic technique in which the mobile phase is driven through the chromatographic bed by electro-osmosis. Capillary electrochromatography is a combination of two analytical techniques, high-performance liquid chromatography and capillary electrophoresis. Capillary electrophoresis aims to separate analytes on the basis of their mass-to-charge ratio by passing a high voltage across ends of a capillary tube, which is filled with the analyte. High-performance liquid chromatography separates analytes by passing them, under high pressure, through a column filled with stationary phase. The interactions between the analytes and the stationary phase and mobile phase lead to the separation of the analytes. In capillary electrochromatography capillaries, packed with HPLC stationary phase, are subjected to a high voltage. Separation is achieved by electrophoretic migration of solutes and differential partitioning.

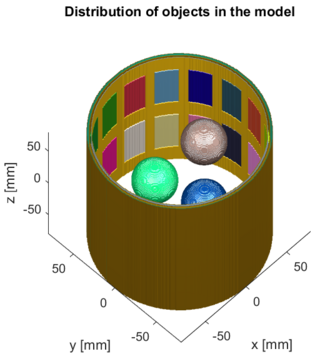

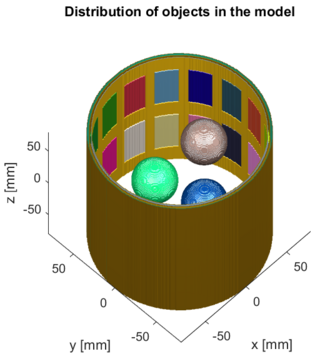

Three-dimensional electrical capacitance tomography also known as electrical capacitance volume tomography (ECVT) is a non-invasive 3D imaging technology applied primarily to multiphase flows. It was introduced in the early 2000s as an extension of the conventional two-dimensional ECT. In conventional electrical capacitance tomography, sensor plates are distributed around a surface of interest. Measured capacitance between plate combinations is used to reconstruct 2D images (tomograms) of material distribution. Because the ECT sensor plates are required to have lengths on the order of the domain cross-section, 2D ECT does not provide the required resolution in the axial dimension. In ECT, the fringing field from the edges of the plates is viewed as a source of distortion to the final reconstructed image and is thus mitigated by guard electrodes. 3D ECT exploits this fringing field and expands it through 3D sensor designs that deliberately establish an electric field variation in all three dimensions. In 3D tomography, the data are acquired in 3D geometry, and the reconstruction algorithm produces the three-dimensional image directly, in contrast to 2D tomography, where 3D information might be obtained by stacking 2D slices reconstructed individually.

Paper-based microfluidics are microfluidic devices that consist of a series of hydrophilic cellulose or nitrocellulose fibers that transport fluid from an inlet through the porous medium to a desired outlet or region of the device, by means of capillary action. This technology builds on the conventional lateral flow test which is capable of detecting many infectious agents and chemical contaminants. The main advantage of this is that it is largely a passively controlled device unlike more complex microfluidic devices. Development of paper-based microfluidic devices began in the early 21st century to meet a need for inexpensive and portable medical diagnostic systems.

Microfluidic diffusional sizing (MDS) is a method to measure the size of particles based on the degree to which they diffuse within a microfluidic laminar flow. It allows size measurements to be taken from extremely small quantities of material (nano-grams) and is particularly useful when sizing molecules which may vary in size depending on their environment - e.g. protein molecules which may unfold or become denatured in unfavourable conditions.