In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure.

Failure rate is the frequency with which an engineered system or component fails, expressed in failures per unit of time. It is usually denoted by the Greek letter λ (lambda) and is often used in reliability engineering.

Prognostics is an engineering discipline focused on predicting the time at which a system or a component will no longer perform its intended function. This lack of performance is most often a failure beyond which the system can no longer be used to meet desired performance. The predicted time then becomes the remaining useful life (RUL), which is an important concept in decision making for contingency mitigation. Prognostics predicts the future performance of a component by assessing the extent of deviation or degradation of a system from its expected normal operating conditions. The science of prognostics is based on the analysis of failure modes, detection of early signs of wear and aging, and fault conditions. An effective prognostics solution is implemented when there is sound knowledge of the failure mechanisms that are likely to cause the degradations leading to eventual failures in the system. It is therefore necessary to have initial information on the possible failures in a product. Such knowledge is important to identify the system parameters that are to be monitored. Potential uses for prognostics is in condition-based maintenance. The discipline that links studies of failure mechanisms to system lifecycle management is often referred to as prognostics and health management (PHM), sometimes also system health management (SHM) or—in transportation applications—vehicle health management (VHM) or engine health management (EHM). Technical approaches to building models in prognostics can be categorized broadly into data-driven approaches, model-based approaches, and hybrid approaches.

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

Ansys, Inc. is an American multinational company with its headquarters based in Canonsburg, Pennsylvania. It develops and markets CAE/multiphysics engineering simulation software for product design, testing and operation and offers its products and services to customers worldwide.

Integrated logistics support (ILS) is a technology in the system engineering to lower a product life cycle cost and decrease demand for logistics by the maintenance system optimization to ease the product support. Although originally developed for military purposes, it is also widely used in commercial customer service organisations.

Flat no-leads packages such as quad-flat no-leads (QFN) and dual-flat no-leads (DFN) physically and electrically connect integrated circuits to printed circuit boards. Flat no-leads, also known as micro leadframe (MLF) and SON, is a surface-mount technology, one of several package technologies that connect ICs to the surfaces of PCBs without through-holes. Flat no-lead is a near chip scale plastic encapsulated package made with a planar copper lead frame substrate. Perimeter lands on the package bottom provide electrical connections to the PCB. Flat no-lead packages usually, but not always, include an exposed thermally conductive pad to improve heat transfer out of the IC. Heat transfer can be further facilitated by metal vias in the thermal pad. The QFN package is similar to the quad-flat package (QFP), and a ball grid array (BGA).

Engineering analysis involves the application of scientific/mathematical analytic principles and processes to reveal the properties and state of a system, device or mechanism under study.

CR-5000 is Zuken's EDA design suite for electronic systems and printed circuit boards aimed at the enterprise market. It was developed to address complex design needs that involve managing the complete development and manufacturing preparation process on an enterprise-wide scale. CR-5000 is made to facilitate the design of complex and high-speed boards, with features aimed at addressing challenges such as signal integrity and electromagnetic compatibility.

NESSUS is a general-purpose, probabilistic analysis program that simulates variations and uncertainties in loads, geometry, material behavior and other user-defined inputs to compute probability of failure and probabilistic sensitivity measures of engineered systems. Because NESSUS uses highly efficient and accurate probabilistic analysis methods, probabilistic solutions can be obtained even for extremely large and complex models. The system performance can be hierarchically decomposed into multiple smaller models and/or analytical equations. Once the probabilistic response is quantified, the results can be used to support risk-informed decisions regarding reliability for safety critical and one-of-a-kind systems, and to maintain a level of quality while reducing manufacturing costs for larger quantity products.

Zemax is a software program used for designing and simulating optical systems. It is widely used in the field of optics and photonics for designing and analyzing the performance of lenses, cameras, telescopes, microscopes, and other optical systems. The software allows engineers and scientists to model the behavior of light as it interacts with various optical components, helping them optimize the design for desired performance.

Reliability of a semiconductor device is the ability of the device to perform its intended function during the life of the device in the field.

OptiY is a design environment software that provides modern optimization strategies and state of the art probabilistic algorithms for uncertainty, reliability, robustness, sensitivity analysis, data-mining and meta-modeling.

Pad cratering is a mechanically induced fracture in the resin between copper foil and outermost layer of fiberglass of a printed circuit board (PCB). It may be within the resin or at the resin to fiberglass interface.

A prediction of reliability is an important element in the process of selecting equipment for use by telecommunications service providers and other buyers of electronic equipment, and it is essential during the design stage of engineering systems life cycle. Reliability is a measure of the frequency of equipment failures as a function of time. Reliability has a major impact on maintenance and repair costs and on the continuity of service.

Physics of failure is a technique under the practice of reliability design that leverages the knowledge and understanding of the processes and mechanisms that induce failure to predict reliability and improve product performance.

Vibration fatigue is a mechanical engineering term describing material fatigue, caused by forced vibration of random nature. An excited structure responds according to its natural-dynamics modes, which results in a dynamic stress load in the material points. The process of material fatigue is thus governed largely by the shape of the excitation profile and the response it produces. As the profiles of excitation and response are preferably analyzed in the frequency domain it is practical to use fatigue life evaluation methods, that can operate on the data in frequency-domain, s power spectral density (PSD).

optiSLang is a software platform for CAE-based sensitivity analysis, multi-disciplinary optimization (MDO) and robustness evaluation. It was originally developed by Dynardo GmbH and provides a framework for numerical Robust Design Optimization (RDO) and stochastic analysis by identifying variables which contribute most to a predefined optimization goal. This includes also the evaluation of robustness, i.e. the sensitivity towards scatter of design variables or random fluctuations of parameters. In 2019, Dynardo GmbH was acquired by Ansys.

Solder fatigue is the mechanical degradation of solder due to deformation under cyclic loading. This can often occur at stress levels below the yield stress of solder as a result of repeated temperature fluctuations, mechanical vibrations, or mechanical loads. Techniques to evaluate solder fatigue behavior include finite element analysis and semi-analytical closed-form equations.

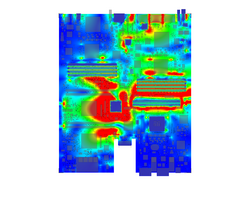

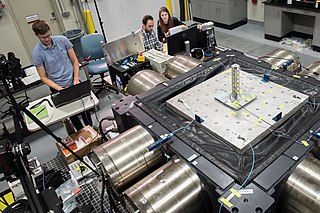

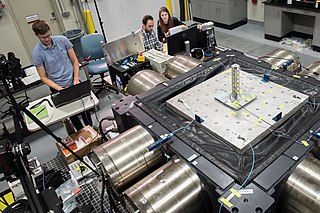

Digital image correlation analyses have applications in material property characterization, displacement measurement, and strain mapping. As such, DIC is becoming an increasingly popular tool when evaluating the thermo-mechanical behavior of electronic components and systems.