It has been suggested that this article be merged into Environmental stress cracking . (Discuss) Proposed since February 2025. |

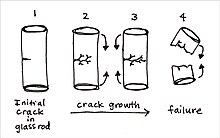

Static fatigue, sometimes referred to as delayed fracture, describes the progressive cracking and eventual failure of materials under a constant, sustained stress. [1] (It is different from fatigue, which refers to the deformation and eventual failure of materials subjected to cyclical stresses.) With static fatigue materials experience damage or failure under stress levels that are lower than their normal ultimate tensile strengths. [2] The exact details vary with the material type and environmental factors, such as moisture presence [3] and temperature. [4] [5] This phenomenon is closely related to stress corrosion cracking. [1]