Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminium combined.

In passive solar building design, windows, walls, and floors are made to collect, store, reflect, and distribute solar energy, in the form of heat in the winter and reject solar heat in the summer. This is called passive solar design because, unlike active solar heating systems, it does not involve the use of mechanical and electrical devices.

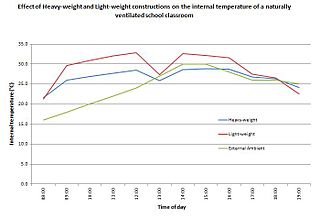

In building design, thermal mass is a property of the mass of a building that enables it to store heat and provide inertia against temperature fluctuations. It is sometimes known as the thermal flywheel effect. The thermal mass of heavy structural elements can be designed to work alongside a construction's lighter thermal resistance components to create energy efficient buildings.

A modular building is a prefabricated building that consists of repeated sections called modules. Modularity involves constructing sections away from the building site, then delivering them to the intended site. Installation of the prefabricated sections is completed on site. Prefabricated sections are sometimes placed using a crane. The modules can be placed side-by-side, end-to-end, or stacked, allowing for a variety of configurations and styles. After placement, the modules are joined together using inter-module connections, also known as inter-connections. The inter-connections tie the individual modules together to form the overall building structure.

A structural insulated panel, or structural insulating panel, (SIP), is a form of sandwich panel used in the construction industry.

An Earthship is a style of architecture developed in the late 20th century to early 21st century by architect Michael Reynolds. Earthships are designed to behave as passive solar earth shelters made of both natural and upcycled materials such as earth-packed tires. Earthships may feature a variety of amenities and aesthetics, and are designed to withstand the extreme temperatures of a desert, managing to stay close to 70 °F (21 °C) regardless of outside weather conditions. Earthship communities were originally built in the desert of northern New Mexico, near the Rio Grande, and the style has spread to small pockets of communities around the globe, in some cases in spite of legal opposition to its construction and adoption.

Tilt-up,tilt-slab or tilt-wall is a type of building and a construction technique using concrete. Though it is a cost-effective technique with a shorter completion time, poor performance in earthquakes has mandated significant seismic retrofit requirements in older buildings.

This page is a list of construction topics.

Green building refers to both a structure and the application of processes that are environmentally responsible and resource-efficient throughout a building's life-cycle: from planning to design, construction, operation, maintenance, renovation, and demolition. This requires close cooperation of the contractor, the architects, the engineers, and the client at all project stages. The Green Building practice expands and complements the classical building design concerns of economy, utility, durability, and comfort. Green building also refers to saving resources to the maximum extent, including energy saving, land saving, water saving, material saving, etc., during the whole life cycle of the building, protecting the environment and reducing pollution, providing people with healthy, comfortable and efficient use of space, and being in harmony with nature Buildings that live in harmony. Green building technology focuses on low consumption, high efficiency, economy, environmental protection, integration and optimization.’

Insulating concrete form or insulated concrete form (ICF) is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs. The forms are interlocking modular units that are dry-stacked and filled with concrete. The units lock together somewhat like Lego bricks and create a form for the structural walls or floors of a building. ICF construction has become commonplace for both low rise commercial and high performance residential construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

A low-energy house is characterized by an energy-efficient design and technical features which enable it to provide high living standards and comfort with low energy consumption and carbon emissions. Traditional heating and active cooling systems are absent, or their use is secondary. Low-energy buildings may be viewed as examples of sustainable architecture. Low-energy houses often have active and passive solar building design and components, which reduce the house's energy consumption and minimally impact the resident's lifestyle. Throughout the world, companies and non-profit organizations provide guidelines and issue certifications to guarantee the energy performance of buildings and their processes and materials. Certifications include passive house, BBC - Bâtiment Basse Consommation - Effinergie (France), zero-carbon house (UK), and Minergie (Switzerland).

A Zero-Energy Building (ZEB), also known as a Net Zero-Energy (NZE) building, is a building with net zero energy consumption, meaning the total amount of energy used by the building on an annual basis is equal to the amount of renewable energy created on the site or in other definitions by renewable energy sources offsite, using technology such as heat pumps, high efficiency windows and insulation, and solar panels.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels for tilt up construction. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

Building insulation is material used in a building to reduce the flow of thermal energy. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation. Often an insulation material will be chosen for its ability to perform several of these functions at once.

Building insulation materials are the building materials that form the thermal envelope of a building or otherwise reduce heat transfer.

GigaCrete refers to a family of green building products based on proprietary non-silica, non-toxic, non-combustible, cementitious, mineral-based binders combined with filler material. GigaCrete building materials do not contain silica-based sands or Portland cement. GigaCrete products are manufactured by a privately held company, GigaCrete, Inc., whose factory headquarters are located in Las Vegas, Nevada.

The Ardea, formerly 3720, is a 30-story 99.06 m (325.0 ft) apartment skyscraper in the South Waterfront district of Portland, Oregon. The building was completed in March 2009, however was turned over in phases allowing occupancy beginning in August 2008. The Ardea was developed by Gerding Edlen, designed by GBD Architects, and constructed by Hoffman Construction. The building was initially designed to be a condominium building but was converted to apartments after the Portland housing and condominium supply outstripped demand. The Ardea joins John Ross Tower as the seventh tallest building in Portland.

Earthquake-resistant or aseismic structures are designed to protect buildings to some or greater extent from earthquakes. While no structure can be entirely impervious to earthquake damage, the goal of earthquake engineering is to erect structures that fare better during seismic activity than their conventional counterparts. According to building codes, earthquake-resistant structures are intended to withstand the largest earthquake of a certain probability that is likely to occur at their location. This means the loss of life should be minimized by preventing collapse of the buildings for rare earthquakes while the loss of the functionality should be limited for more frequent ones.

Studcast concrete, also called "pre-framed concrete", combines relatively thin concrete layers with cold formed steel framing to create hybrid panels; the result is a panelized system usable for cladding, curtain walls, shaft walls, and load-bearing exterior and interior walls. Studcast panels install in the same manner as prefabricated steel stud panels. The technology is applicable for both factory prefabrication and site-cast (tilt-up) wall construction on almost all types of buildings, including multifamily housing, schools, industrial, commercial and institutional structures.

Prefabs were a major part of the delivery plan to address the United Kingdom's post–Second World War housing shortage. They were envisaged by war-time prime minister Winston Churchill in March 1944, and legally outlined in the Housing Act 1944.