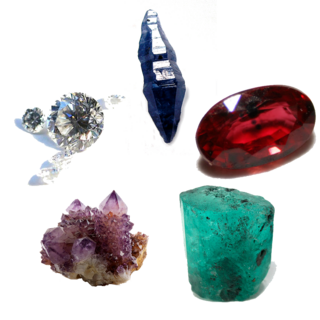

Emerald is a gemstone and a variety of the mineral beryl (Be3Al2(SiO3)6) colored green by trace amounts of chromium or sometimes vanadium. Beryl has a hardness of 7.5–8 on the Mohs scale. Most emeralds are highly included, so their toughness (resistance to breakage) is classified as generally poor. Emerald is a cyclosilicate.

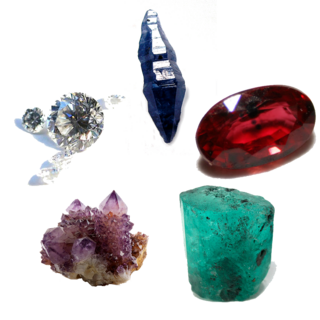

A gemstone is a piece of mineral crystal which, in cut and polished form, is used to make jewelry or other adornments. However, certain rocks and occasionally organic materials that are not minerals are also used for jewelry and are therefore often considered to be gemstones as well. Most gemstones are hard, but some soft minerals are used in jewelry because of their luster or other physical properties that have aesthetic value. Rarity and notoriety are other characteristics that lend value to gemstones.

Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminium oxide (α-Al2O3) with trace amounts of elements such as iron, titanium, chromium, vanadium, or magnesium. The name sapphire is derived via the Latin "sapphirus" from the Greek "sappheiros", which referred to lapis lazuli. It is typically blue, but natural "fancy" sapphires also occur in yellow, purple, orange, and green colors; "parti sapphires" show two or more colors. Red corundum stones also occur, but are called rubies rather than sapphires. Pink-colored corundum may be classified either as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules. Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs. Sapphire is the birthstone for September and the gem of the 45th anniversary. A sapphire jubilee occurs after 65 years.

A ruby is a pinkish red to blood-red colored gemstone, a variety of the mineral corundum. Ruby is one of the most popular traditional jewelry gems and is very durable. Other varieties of gem-quality corundum are called sapphires. Ruby is one of the traditional cardinal gems, alongside amethyst, sapphire, emerald, and diamond. The word ruby comes from ruber, Latin for red. The color of a ruby is due to the element chromium.

The mineral or gemstone chrysoberyl is an aluminate of beryllium with the formula BeAl2O4. The name chrysoberyl is derived from the Greek words χρυσός chrysos and βήρυλλος beryllos, meaning "a gold-white spar". Despite the similarity of their names, chrysoberyl and beryl are two completely different gemstones, although they both contain beryllium. Chrysoberyl is the third-hardest frequently encountered natural gemstone and lies at 8.5 on the Mohs scale of mineral hardness, between corundum (9) and topaz (8).

Lustre or luster is the way light interacts with the surface of a crystal, rock, or mineral. The word traces its origins back to the Latin lux, meaning "light", and generally implies radiance, gloss, or brilliance.

Cubic zirconia (CZ) is the cubic crystalline form of zirconium dioxide (ZrO2). The synthesized material is hard and usually colorless, but may be made in a variety of different colors. It should not be confused with zircon, which is a zirconium silicate (ZrSiO4). It is sometimes erroneously called cubic zirconium.

Gemology or gemmology is the science dealing with natural and artificial gemstone materials. It is a geoscience and a branch of mineralogy. Some jewelers are academically trained gemologists and are qualified to identify and evaluate gems.

Pleochroism is an optical phenomenon in which a substance has different colors when observed at different angles, especially with polarized light.

The Czochralski method, also Czochralski technique or Czochralski process, is a method of crystal growth used to obtain single crystals of semiconductors, metals, salts and synthetic gemstones. The method is named after Polish scientist Jan Czochralski, who invented the method in 1915 while investigating the crystallization rates of metals. He made this discovery by accident: instead of dipping his pen into his inkwell, he dipped it in molten tin, and drew a tin filament, which later proved to be a single crystal.

An asterism is a star-shaped concentration of reflected or refracted light from a gemstone. Asterisms can appear when a suitable stone is cut en cabochon i.e. shaped and polished.

The Bridgman–Stockbarger method, or Bridgman–Stockbarger technique, is named after Harvard physicist Percy Williams Bridgman (1882–1961) and MIT physicist Donald C. Stockbarger (1895–1952). The method includes two similar but distinct techniques primarily used for growing boules, but which can be used for solidifying polycrystalline ingots as well.

Diamond clarity is the quality of diamonds that relates to the existence and visual appearance of internal characteristics of a diamond called inclusions, and surface defects, called blemishes. Clarity is one of the four Cs of diamond grading, the others being carat, color, and cut.

A diamond simulant, diamond imitation or imitation diamond is an object or material with gemological characteristics similar to those of a diamond. Simulants are distinct from synthetic diamonds, which are actual diamonds exhibiting the same material properties as natural diamonds. Enhanced diamonds are also excluded from this definition. A diamond simulant may be artificial, natural, or in some cases a combination thereof. While their material properties depart markedly from those of diamond, simulants have certain desired characteristics—such as dispersion and hardness—which lend themselves to imitation. Trained gemologists with appropriate equipment are able to distinguish natural and synthetic diamonds from all diamond simulants, primarily by visual inspection.

Tairus is a synthetic gemstone manufacturer. It was formed in 1989 as part of Mikhail Gorbachev's perestroika initiative to establish a joint venture between the Russian Academy of Sciences and Tairus Created Gems Co Ltd. of Bangkok, Thailand. Today Tairus is a major supplier of hydrothermally grown gemstones to the jewellery industry. Later, Tairus became a privately held enterprise, operating out of its Bangkok distribution hub under the trade name Tairus, owned by Tairus Created Gems Co Ltd. of Bangkok, Thailand.

The Verneuil method, also called flame fusion, was the first commercially successful method of manufacturing synthetic gemstones, developed in the late 1883 by the French chemist Auguste Verneuil. It is primarily used to produce the ruby, sapphire and padparadscha varieties of corundum, as well as the diamond simulants rutile, strontium titanate and spinel. The principle of the process involves melting a finely powdered substance using an oxyhydrogen flame, and crystallising the melted droplets into a boule. The process is considered to be the founding step of modern industrial crystal growth technology, and remains in wide use to this day.

Hydrothermal synthesis includes the various techniques of crystallizing substances from high-temperature aqueous solutions at high vapor pressures; also termed "hydrothermal method". The term "hydrothermal" is of geologic origin. Geochemists and mineralogists have studied hydrothermal phase equilibria since the beginning of the twentieth century. George W. Morey at the Carnegie Institution and later, Percy W. Bridgman at Harvard University did much of the work to lay the foundations necessary to containment of reactive media in the temperature and pressure range where most of the hydrothermal work is conducted.

The flux method of crystal growth is a method where the components of the desired substance are dissolved in a solvent (flux). The method is particularly suitable for crystals needing to be free from thermal strain. It takes place in a crucible made of highly stable, non-reactive material. For production of oxide crystals, metals such as platinum, tantalum, and niobium are common. Production of metallic crystals generally uses crucibles made from ceramics such as alumina, zirconia, and boron nitride. The crucibles and their contents are often isolated from the air for reaction, either by sealing them in a quartz ampoule or by using a furnace with atmosphere control. A saturated solution is prepared by keeping the constituents of the desired crystal and the flux at a temperature slightly above the saturation temperature long enough to form a complete solution. Then the crucible is cooled in order to allow the desired material to precipitate. Crystal formation can begin by spontaneous nucleation or may be encouraged by the use of a seed. As material precipitates out of the solution, the amount of solute in the flux decreases and the temperature at which the solution is saturated lowers. This process repeats itself as the furnace continues to cool until the solution reaches its melting point or the reaction is stopped artificially. In flux method synthesis, divergent crystal growth kinetics may emerge, with a small number of crystallites growing at the expense of neighbouring ones, resulting in abnormal grain growth.

The micro-pulling-down (μ-PD) method is a crystal growth technique based on continuous transport of the melted substance through micro-channel(s) made in a crucible bottom. Continuous solidification of the melt is progressed on a liquid/solid interface positioned under the crucible. In a steady state, both the melt and the crystal are pulled-down with a constant velocity.

The Kyropoulos method, KY method, or Kyropoulos technique, is a method of bulk crystal growth used to obtain single crystals.