Related Research Articles

Smoke is a suspension of airborne particulates and gases emitted when a material undergoes combustion or pyrolysis, together with the quantity of air that is entrained or otherwise mixed into the mass. It is commonly an unwanted by-product of fires, but may also be used for pest control (fumigation), communication, defensive and offensive capabilities in the military, cooking, or smoking. It is used in rituals where incense, sage, or resin is burned to produce a smell for spiritual or magical purposes. It can also be a flavoring agent and preservative.

Cleaning is the process of removing unwanted substances, such as dirt, infectious agents, and other impurities, from an object or environment. Cleaning is often performed for aesthetic, hygienic, functional, environmental, or safety purposes. Cleaning occurs in many different contexts, and uses many different methods. Several occupations are devoted to cleaning.

The pyrolysis process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements pyro "fire", "heat", "fever" and lysis "separating".

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

Activated carbon, also called activated charcoal, is a form of carbon commonly used to filter contaminants from water and air, among many other uses. It is processed (activated) to have small, low-volume pores that increase the surface area available for adsorption or chemical reactions. Activation is analogous to making popcorn from dried corn kernels: popcorn is light, fluffy, and its kernels have a high surface-area-to-volume ratio. Activated is sometimes replaced by active.

In metallurgy, a flux is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining.

Polymer degradation is the reduction in the physical properties of a polymer, such as strength, caused by changes in its chemical composition. Polymers and particularly plastics are subject to degradation at all stages of their product life cycle, including during their initial processing, use, disposal into the environment and recycling. The rate of this degradation varies significantly; biodegradation can take decades, whereas some industrial processes can completely decompose a polymer in hours.

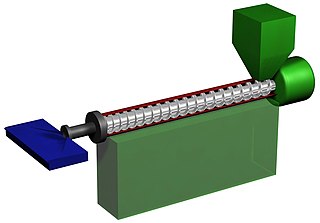

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

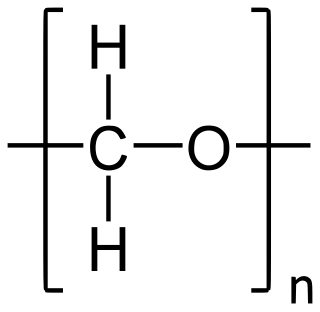

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Kocetal, Ultraform, Celcon, Ramtal, Duracon, Kepital, Polypenco, Tenac and Hostaform.

Thermogravimetric analysis or thermal gravimetric analysis (TGA) is a method of thermal analysis in which the mass of a sample is measured over time as the temperature changes. This measurement provides information about physical phenomena, such as phase transitions, absorption, adsorption and desorption; as well as chemical phenomena including chemisorptions, thermal decomposition, and solid-gas reactions.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobiles, and bicycle frames. Advancements in powder coating technology like UV curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF to be powder coated due to the minimum heat and oven dwell time required to process these components.

Fusion bonded epoxy coating, also known as fusion-bond epoxy powder coating and commonly referred to as FBE coating, is an epoxy-based powder coating that is widely used to protect steel pipe used in pipeline construction from corrosion. It is also commonly used to protect reinforcing bars and on a wide variety of piping connections, valves etc. FBE coatings are thermoset polymer coatings. They come under the category of protective coatings in paints and coating nomenclature. The name fusion-bond epoxy is due to resigning cross-link and the application method, which is different from a conventional paint. In 2020 the market size was quoted at 12 billion dollars.

Hydrogen production is the family of industrial methods for generating hydrogen gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming of natural gas and other light hydrocarbons, partial oxidation of heavier hydrocarbons, and coal gasification. Other methods of hydrogen production include biomass gasification, zero-CO2-emission methane pyrolysis, and electrolysis of water. The latter processes, methane pyrolysis as well as water electrolysis can be done directly with any source of electricity, such as solar power.

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Thermal spraying techniques are coating processes in which melted materials are sprayed onto a surface. The "feedstock" is heated by electrical or chemical means.

Ceramic foam is a tough foam made from ceramics. Manufacturing techniques include impregnating open-cell polymer foams internally with ceramic slurry and then firing in a kiln, leaving only ceramic material. The foams may consist of several ceramic materials such as aluminium oxide, a common high-temperature ceramic, and gets insulating properties from the many tiny air-filled voids within the material.

A thermal blanket is a device used in thermal desorption to clean soil contamination. The primary function of a thermal blanket is to heat the soil to the boiling point of the contaminants so that they break down. A vacuum pulls the resulting gas into a separate air cleaner that may use various methods, such as carbon filters and high-heat ovens, to completely destroy the contaminants. Aside from evaporation and volatilization, the contaminants may also be removed from the soil through other mechanisms such as steam distillation, pyrolysis, oxidation, and other chemical reactions.

Green nanotechnology refers to the use of nanotechnology to enhance the environmental sustainability of processes producing negative externalities. It also refers to the use of the products of nanotechnology to enhance sustainability. It includes making green nano-products and using nano-products in support of sustainability.

A spinneret is a device used to extrude a polymer solution or polymer melt to form fibers. Streams of viscous polymer exit via the spinneret into air or liquid leading to a phase inversion which allows the polymer to solidify. The individual polymer chains tend to align in the fiber because of viscous flow. This airstream liquid-to-fiber formation process is similar to the production process for cotton candy. The fiber production process is generally referred to as "spinning". Depending on the type of spinneret used, either solid or hollow fibers can be formed. Spinnerets are also used for electrospinning and electrospraying applications. They are sometimes called coaxial needles, or coaxial emitters.

The conservation and restoration of frescoes is the process of caring for and maintaining frescos, and includes documentation, examination, research, and treatment to insure their long-term viability, when desired.

References

- ↑ Udo Heffungs (June 2010). "Effective Spinneret Cleaning". Fiber Journal. Retrieved 23 December 2016.

- 1 2 3 4 5 6 7 Gary Davis & Keith Brown (April 1996). "Cleaning Metal Parts and Tooling" (PDF). Pollution Prevention Regional Information Center. Process Heating. Archived from the original (PDF) on 4 March 2016. Retrieved 23 December 2016.

- 1 2 "A Look at Thermal Cleaning Technology". ThermalProcessing.org. Process Examiner. 14 March 2014. Retrieved 23 December 2016.

- 1 2 3 4 5 6 7 8 9 10 11 Mainord, Kenneth (September 1994). "Cleaning with Heat: Old Technology with a Bright New Future" (PDF). Pollution Prevention Regional Information Center. The Magazine of Critical Cleaning Technology. Archived from the original (PDF) on 8 December 2015. Retrieved 23 December 2016.

- ↑ Ewald Schwing; Horst Uhrner (7 October 1999). "Method for removing polymer deposits which have formed on metal or ceramic machine parts, equipment and tools". Espacenet. European Patent Office. Retrieved 23 December 2016.

- ↑ Herbert Kenneth Staffin; Robert A. Koelzer (28 November 1974). "Cleaning objects in hot fluidised bed - with neutralization of resultant acidic gas esp. by alkaline metals cpds". Espacenet. European Patent Office. Retrieved 23 December 2016.

- 1 2 Thomas S. Dwan (2 September 1980). "Process for vacuum pyrolysis removal of polymers from various objects". Espacenet. European Patent Office. Retrieved 23 December 2016.

- ↑ "Vacuum pyrolysis systems". thermal-cleaning.com. Retrieved 24 December 2016.

- ↑ "Paint Stripping: Reducing Waste and Hazardous Material". Minnesota Technical Assistance Program. University of Minnesota. July 2008. Archived from the original on 8 December 2015. Retrieved 23 December 2016.