A silicone or polysiloxane is any of a number of polymers that include any synthetic compound made up of repeating units of siloxane, which is a chain of alternating silicon atoms and oxygen atoms, combined with carbon, hydrogen, and sometimes other elements.

A heat sink is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature at optimal levels. In computers, heat sinks are used to cool CPUs, GPUs, and some chipsets and RAM modules. Heat sinks are used with high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature.

Computer cooling is required to remove the waste heat produced by computer components, to keep components within permissible operating temperature limits. Components that are susceptible to temporary malfunction or permanent failure if overheated include integrated circuits such as central processing units (CPUs), chipset, graphics cards, and hard disk drives.

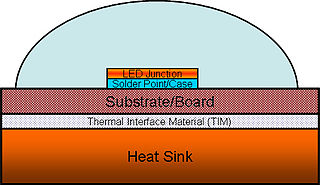

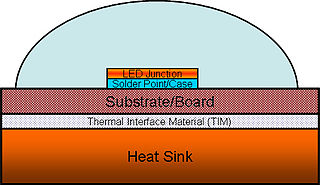

A thermal interface material is any material that is inserted between two components in order to enhance the thermal coupling between them. A common use is heat dissipation, in which the TIM is inserted between a heat-producing device and a heat-dissipating device.

A hermetic seal is any type of sealing that makes a given object airtight. The term originally applied to airtight glass containers, but as technology advanced it applied to a larger category of materials, including rubber and plastics. Hermetic seals are essential to the correct and safe functionality of many electronic and healthcare products. Used technically, it is stated in conjunction with a specific test method and conditions of use.

Beryllium oxide (BeO), also known as beryllia, is an inorganic compound with the formula BeO. This colourless solid is a notable electrical insulator with a higher thermal conductivity than any other non-metal except diamond, and exceeds that of most metals. As an amorphous solid, beryllium oxide is white. Its high melting point leads to its use as a refractory material. It occurs in nature as the mineral bromellite. Historically and in materials science, beryllium oxide was called glucina or glucinium oxide.

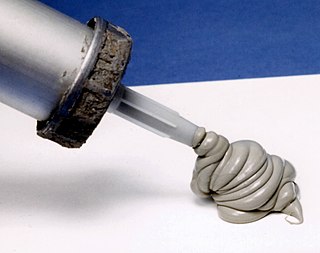

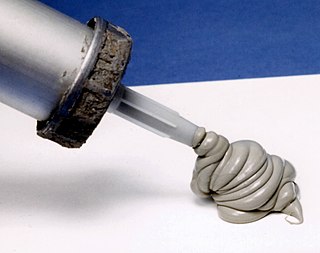

Silicone grease, sometimes called dielectric grease, is a waterproof grease made by combining a silicone oil with a thickener. Most commonly, the silicone oil is polydimethylsiloxane (PDMS) and the thickener is amorphous fumed silica. Using this formulation, silicone grease is a translucent white viscous paste, with exact properties dependent on the type and proportion of the components. More specialized silicone greases are made from fluorinated silicones or, for low-temperature applications, PDMS containing some phenyl substituents in place of methyl groups. Other thickeners may be used, including stearates and powdered polytetrafluorethylene (PTFE).

Thermal adhesive is a type of thermally conductive glue used for electronic components and heat sinks. It can be available as a paste or as a double-sided tape.

A diffusion barrier is a thin layer of metal usually placed between two other metals. It is done to act as a barrier to protect either one of the metals from corrupting the other.

Arctic Silver Inc. is a privately owned engineering corporation which develops and manufactures thermally conductive compounds and thermal adhesives for the application of heat sinks to high-powered electronic components such as processors, LEDs, chipsets and other electronic devices. Founded in 1999, the company's facilities are located in Visalia, California, US.

Silicone rubber is an elastomer composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost. Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C while still maintaining its useful properties. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; apparel such as undergarments, sportswear, and footwear; electronics; medical devices and implants; and in home repair and hardware with products such as silicone sealants.

All electronic devices and circuitry generate excess heat and thus require thermal management to improve reliability and prevent premature failure. The amount of heat output is equal to the power input, if there are no other energy interactions. There are several techniques for cooling including various styles of heat sinks, thermoelectric coolers, forced air systems and fans, heat pipes, and others. In cases of extreme low environmental temperatures, it may actually be necessary to heat the electronic components to achieve satisfactory operation.

The role of the substrate in power electronics is to provide the interconnections to form an electric circuit, and to cool the components. Compared to materials and techniques used in lower power microelectronics, these substrates must carry higher currents and provide a higher voltage isolation. They also must operate over a wide temperature range.

In computing and electronics, thermal pads are a pre-formed square or rectangle of solid material commonly found on the underside of heatsinks to aid the conduction of heat away from the component being cooled and into the heatsink. Thermal pads and thermal compound are used to fill air gaps caused by imperfectly flat or smooth surfaces which should be in thermal contact; they would not be needed between perfectly flat and smooth surfaces. Thermal pads are relatively firm at room temperature, but become soft and well able to fill gaps at higher temperatures.

In electronics, TO-3 is a designation for a standardized metal semiconductor package used for power semiconductors, including transistors, silicon controlled rectifiers, and, integrated circuits. TO stands for "Transistor Outline" and relates to a series of technical drawings produced by JEDEC.

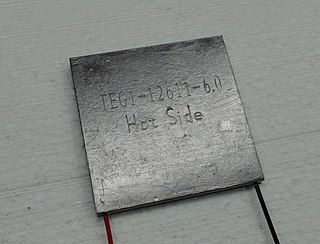

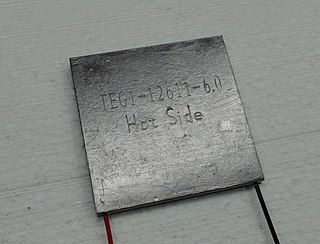

A thermoelectric generator (TEG), also called a Seebeck generator, is a solid state device that converts heat flux directly into electrical energy through a phenomenon called the Seebeck effect. Thermoelectric generators function like heat engines, but are less bulky and have no moving parts. However, TEGs are typically more expensive and less efficient.

High power light-emitting diodes (LEDs) can use 350 milliwatts or more in a single LED. Most of the electricity in an LED becomes heat rather than light. If this heat is not removed, the LEDs run at high temperatures, which not only lowers their efficiency, but also makes the LED less reliable. Thus, thermal management of high power LEDs is a crucial area of research and development. It is necessary to limit both the junction and the phosphor particles temperatures to a value that will guarantee the desired LED lifetime.

A heat spreader transfers energy as heat from a hotter source to a colder heat sink or heat exchanger. There are two thermodynamic types, passive and active. The commonest sort of passive heat spreader is a plate or block of material having high thermal conductivity, such as copper, aluminum, or diamond. An active heat spreader speeds up heat transfer with expenditure of energy as work supplied by an external source.

Solid is one of the four fundamental states of matter. The atoms in a solid are closely packed together and contain the least amount of kinetic energy. A solid is characterized by structural rigidity and resistance to a force applied to the surface. Unlike a liquid, a solid object does not flow to take on the shape of its container, nor does it expand to fill the entire available volume like a gas. The atoms in a solid are bound to each other, either in a regular geometric lattice, or irregularly. Solids cannot be compressed with little pressure whereas gases can be compressed with little pressure because the molecules in a gas are loosely packed.

An electrically conductive adhesive is a glue that is primarily used for electronics.