Airsoft, also known as "MilSims" in Japan where it was first invented, is a team-based shooting game in which participants eliminate opposing players out of play by shooting them with spherical plastic projectiles shot from airsoft guns.

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

A hallmark is an official mark or series of marks struck on items made of metal, mostly to certify the content of noble metals—such as platinum, gold, silver and in some nations, palladium. In a more general sense, the term hallmark can also be used to refer to any distinguishing mark.

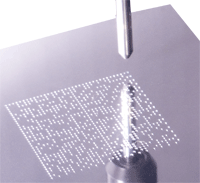

Laser engraving is the practice of using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which in some cases, also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.

Zebra Technologies Corporation is an American mobile computing company specializing in technology used to sense, analyze, and act in real time, sometimes known as smart data capture. The company manufactures and sells marking, tracking, and computer printing technologies. Its products include mobile computers and tablets, software, thermal barcode label and receipt printers, RFID smart label printers/encoders/fixed & handheld readers/antennas, autonomous mobile robots (AMR’s) & machine vision (MV), and fixed industrial scanning hardware & software.

Integrated Micro-electronics, Inc. provides electronics manufacturing services (EMS) and power semiconductor assembly and test services (SATS) with manufacturing facilities in Asia, Europe, and North America. Its headquarters is located in Biñan, Laguna.

Valeo is a French global automotive supplier headquarters in France, listed on the Paris Stock Exchange. It supplies a wide range of products to automakers and the aftermarket. The Group employs 113,600 people in 33 countries worldwide. It has 186 production plants, 59 R&D centers and 15 distribution platforms. Its strategy is focused on innovation and development in high-growth potential regions and emerging countries. In 2018, Valeo's sales rose 4% to €19.1 billion. It also ranked as France's leading patent filer from 2016 to 2018.

The British Standards Institution (BSI) is the national standards body of the United Kingdom. BSI produces technical standards on a wide range of products and services and also supplies certification and standards-related services to businesses.

Direct part marking (DPM) is a process to permanently mark parts with product information including serial numbers, part numbers, date codes, and barcodes. This is done to allow the tracking of parts through the full life cycle.

Laser bonding is a marking technique that uses lasers to bond an additive marking substance to a substrate.

Comau is an Italian multinational company in the automation field based in Turin, Italy. It is a part of the automaker Stellantis. The company is present in 13 countries and employs 4,000 people.

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together.

Amada Weld Tech, a subsidiary of Amada Weld Tech Co., Ltd., designs and manufactures equipment and systems for resistance welding, laser welding, laser marking, laser cutting, laser micro machining, hermetic sealing, micro tig welding, and hot bar reflow soldering and bonding. Established in 1948, AMADA WELD TECH is headquartered in Monrovia, California, US. The company's equipment is used in numerous industries, chief among which are medical, aerospace, automotive, batteries, and electronic components. Amada Weld Tech has approximately 200 employees, with 7 sales and manufacturing offices serving about 12,000 customers worldwide. More than 80,000 items are manufactured annually. The company is certified to ISO 9001:2015, China Compulsory Certificate (CCC), European Conformity (CE), and Canadian Standards Association (CSA) quality certifications.

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching include photo etching, chemical etching, photo chemical etching and photochemical machining. It is mostly used on metals, though other materials are increasingly important. It was developed from armor-decorating and printing etching processes developed during the Renaissance as alternatives to engraving on metal. The process essentially involves bathing the cutting areas in a corrosive chemical known as an etchant, which reacts with the material in the area to be cut and causes the solid material to be dissolved; inert substances known as maskants are used to protect specific areas of the material as resists.

The TRUMPF Group is a German industrial machine manufacturing company. It is a family-owned company with its head office in Ditzingen near Stuttgart. TRUMPF is one of the world's biggest providers of machine tools. With more than 70 operative subsidiaries, the TRUMPF Group is represented in all important markets worldwide. Its production facilities are based in China, Germany, France, the UK, Italy, Japan, Mexico, Austria, Poland, Switzerland, the Czech Republic and the US.

Mettler Toledo is a multinational manufacturer of scales and analytical instruments. It is the largest provider of weighing instruments for use in laboratory, industrial, and food retailing applications. The company also provides various analytical instruments, process analytics instruments, and end-of-line inspection systems. The company operates worldwide with 70% of net sales, derived in equal parts, from Europe and from the Americas. Asian business is included in the remaining 30%. Mettler Toledo is headquartered in Switzerland and incorporated in the United States.

Digital manufacturing is an integrated approach to manufacturing that is centered around a computer system. The transition to digital manufacturing has become more popular with the rise in the quantity and quality of computer systems in manufacturing plants. As more automated tools have become used in manufacturing plants it has become necessary to model, simulate, and analyze all of the machines, tooling, and input materials in order to optimize the manufacturing process. Overall, digital manufacturing can be seen sharing the same goals as computer-integrated manufacturing (CIM), flexible manufacturing, lean manufacturing, and design for manufacturability (DFM). The main difference is that digital manufacturing was evolved for use in the computerized world.