A lubricant is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity.

A tablet is a pharmaceutical oral dosage form or solid unit dosage form. Tablets may be defined as the solid unit dosage form of medication with suitable excipients. It comprises a mixture of active substances and excipients, usually in powder form, that are pressed or compacted into a solid dose. The main advantages of tablets are that they ensure a consistent dose of medicine that is easy to consume.

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves the sealing of piston rings, and cools the engine by carrying heat away from moving parts.

A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts.

In mechanics, compressive strength is the capacity of a material or structure to withstand loads tending to reduce size (compression). It is opposed to tensile strength which withstands loads tending to elongate, resisting tension. In the study of strength of materials, compressive strength, tensile strength, and shear strength can be analyzed independently.

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical or chemical. The study of wear and related processes is referred to as tribology.

Tribology is the science and engineering of understanding friction, lubrication and wear phenomena for interacting surfaces in relative motion. It is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. Subfields of tribology include biotribology, nanotribology and space tribology. It is also related to other areas such as the coupling of corrosion and tribology in tribocorrosion and the contact mechanics of how surfaces in contact deform. Approximately 20% of the total energy expenditure of the world is due to the impact of friction and wear in the transportation, manufacturing, power generation, and residential sectors.

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

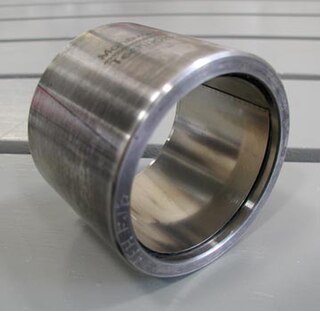

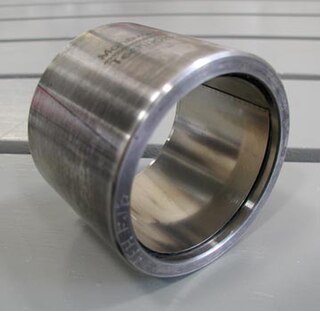

A plain bearing, or more commonly sliding contact bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the part of the shaft in contact with the bearing slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

Timken OK Load is a standardized measurement that indicates the possible performance of extreme pressure (EP) additives in a lubricating grease or oil. The units of measurement are pounds-force or kilograms-force. This measurement is performed using a special test machine and standard block and ring test specimens.

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

An excipient is a substance formulated alongside the active ingredient of a medication. They may be used to enhance the active ingredient’s therapeutic properties; to facilitate drug absorption; to reduce viscosity; to enhance solubility; to improve long-term stabilization ; or to add bulk to solid formulations that have small amounts of potent active ingredients. During the manufacturing process, excipients can improve the handling of active substances and facilitate powder flow. The choice of excipients depends on factors such as the intended route of administration, the dosage form, and compatibility with the active ingredient.

Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil.

A tribometer is an instrument that measures tribological quantities, such as coefficient of friction, friction force, and wear volume, between two surfaces in contact. It was invented by the 18th century Dutch scientist Musschenbroek

Mohawk Innovative Technology, Inc. is an American product and research and development technology company that develops oil-free foil bearings, magnetic bearings and non-contacting foil seals for high-speed rotating machinery, such as gas turbine engines, turbochargers, compressors, cryogenic pumps, variable high-speed motors/generators and machines.

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

The plane strain compression test is a specialized test used on some materials ranging from metals to soils.

Oxygen compatibility is the issue of compatibility of materials for service in high concentrations of oxygen. It is a critical issue in space, aircraft, medical, underwater diving and industrial applications. Aspects include effects of increased oxygen concentration on the ignition and burning of materials and components exposed to these concentrations in service.

Rolling Contact Fatigue (RCF) is a phenomenon that occurs in mechanical components relating to rolling/sliding contact, such as railways, gears, and bearings. It is the result of the process of fatigue due to rolling/sliding contact. The RCF process begins with cyclic loading of the material, which results in fatigue damage that can be observed in crack-like flaws, like white etching cracks. These flaws can grow into larger cracks under further loading, potentially leading to fractures.