Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

A heating element is a device used for conversion of electric energy into heat, consisting of a heating resistor and accessories. Heat is generated by the passage of electric current through a resistor through a process known as Joule heating. Heating elements are used in household appliances, industrial equipment, and scientific instruments enabling them to perform tasks such as cooking, warming, or maintaining specific temperatures higher than the ambient.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, furnace or A/C elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU, sometimes exhausting air to the atmosphere and bringing in fresh air. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

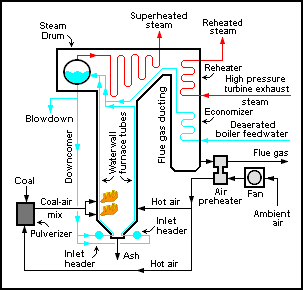

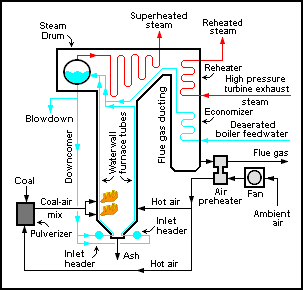

A thermal power station, also known as a thermal power plant, is a type of power station in which the heat energy generated from various fuel sources is converted to electrical energy. The heat from the source is converted into mechanical energy using a thermodynamic power cycle. The most common cycle involves a working fluid heated and boiled under high pressure in a pressure vessel to produce high-pressure steam. This high pressure-steam is then directed to a turbine, where it rotates the turbine's blades. The rotating turbine is mechanically connected to an electric generator which converts rotary motion into electricity. Fuels such as natural gas or oil can also be burnt directly in gas turbines, skipping the steam generation step. These plants can be of the open cycle or the more efficient combined cycle type.

An air preheater is any device designed to heat air before another process, with the primary objective of increasing the thermal efficiency of the process. They may be used alone or to replace a recuperative heat system or to replace a steam coil.

Electric heating is a process in which electrical energy is converted directly to heat energy. Common applications include space heating, cooking, water heating and industrial processes. An electric heater is an electrical device that converts an electric current into heat. The heating element inside every electric heater is an electrical resistor, and works on the principle of Joule heating: an electric current passing through a resistor will convert that electrical energy into heat energy. Most modern electric heating devices use nichrome wire as the active element; the heating element, depicted on the right, uses nichrome wire supported by ceramic insulators.

Economizers, or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) may all use economizers. In simple terms, an economizer is a heat exchanger.

A reaction calorimeter is a calorimeter that measures the amount of energy released or absorbed by a chemical reaction. It does this by measuring the total change in temperature of an exact amount of water in a vessel.

A convection heater, also known as a convector heater, is a type of heater that utilizes convection currents to heat and circulate air. These currents move through the appliance and across its heating element, using thermal conduction to warm the air and decrease its density relative to colder air, causing it to rise.

An oil burner is a heating device which burns #1, #2 and #6 heating oils, diesel fuel or other similar fuels. In the United States, ultra low sulfur #2 diesel is the common fuel used. It is dyed red to show that it is road-tax exempt. In most markets of the United States, heating oil is the same specification of fuel as on-road un-dyed diesel.

A heater core is a radiator-like device used in heating the cabin of a vehicle. Hot coolant from the vehicle's engine is passed through a winding tube of the core, a heat exchanger between coolant and cabin air. Fins attached to the core tubes serve to increase surface area for heat transfer to air that is forced past them by a fan, thereby heating the passenger compartment.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

An industrial furnace, also known as a direct heater or a direct fired heater, is a device used to provide heat for an industrial process, typically higher than 400 degrees Celsius. They are used to provide heat for a process or can serve as reactor which provides heats of reaction. Furnace designs vary as to its function, heating duty, type of fuel and method of introducing combustion air. Heat is generated by an industrial furnace by mixing fuel with air or oxygen, or from electrical energy. The residual heat will exit the furnace as flue gas. These are designed as per international codes and standards the most common of which are ISO 13705 / American Petroleum Institute (API) Standard 560. Types of industrial furnaces include batch ovens, metallurgical furnaces, vacuum furnaces, and solar furnaces. Industrial furnaces are used in applications such as chemical reactions, cremation, oil refining, and glasswork.

A thermic fluid heater (TFH), also known as a thermal oil heater, is a device used for indirect heat transfer through a thermic fluid. It heats the fluid to a desired temperature and then transfers that heat to various processes without any direct contact between the heating source and the product. This type of heater is commonly used in industries where precise temperature control is essential and where high temperatures are required, such as in chemical processing, textile, pharmaceuticals, oil, gas, and food processing.

A water jacket furnace is a type of blast furnace used to smelt non-ferrous metallic ores, most typically ores of copper or silver-lead. It takes its name from the water jacket arrangement used to cool the lower furnace casing and prolong the life of the furnace hearth. Nearly entirely replaced, by flash smelting of ore concentrates, the water jacket furnace is now virtually an obsolete technology.