A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being "forced" or supplied above atmospheric pressure.

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also describe plants where steel semi-finished casting products are made, from molten pig iron or from scrap.

A bloomery is a type of furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. A bloomery's product is a porous mass of iron and slag called a bloom. This mix of slag and iron in the bloom, termed sponge iron, is usually consolidated and further forged into wrought iron. The bloomery has now largely been superseded by the blast furnace, which produces pig iron.

Onota was a village in the Upper Peninsula of the U.S. state of Michigan. It was located on the Grand Island Bay of Lake Superior near the present-day community of Christmas about five miles (8 km) west of Munising in Alger County. The site of Onota is within the Bay Furnace Campground and Picnic Area of the Hiawatha National Forest. The remains of Bay Furnace, a blast furnace used for smelting iron, is the only extant remnant of the town. Bay Furnace was listed on the National Register of Historic Places and designated a Michigan State Historic Site in 1971.

The Katahdin Iron Works is a Maine state historic site located in the unorganized township of the same name. It is the site of an ironworks which operated from 1845 to 1890. In addition to the kilns of the ironworks, the community was served by a railroad and had a 100-room hotel. The site was listed on the National Register of Historic Places in 1969.

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania iron producer from 1742 until it was shut down in 1883. The furnaces, support buildings and surrounding community have been preserved as a historical site and museum, providing a glimpse into Lebanon County's industrial past. The site is the only intact charcoal-burning iron blast furnace in its original plantation in the western hemisphere. Established by Peter Grubb in 1742, Cornwall Furnace was operated during the Revolution by his sons Curtis and Peter Jr. who were major arms providers to George Washington. Robert Coleman acquired Cornwall Furnace after the Revolution and became Pennsylvania's first millionaire. Ownership of the furnace and its surroundings was transferred to the Commonwealth of Pennsylvania in 1932.

The Sterling Iron Works owned by Peter Townsend was one of the first steel and iron manufacturers in the American colonies and the first steel producer in the colony of New York. The company was most famous for forging the Hudson River Chain that kept the British Navy from sailing up the Hudson during the American Revolution, and served to protect the strategically important fort at West Point. The works were operational from 1761 to 1842.

The Oregon Iron Company was an iron smelting company located in what is now Lake Oswego, Oregon. The company was established in 1865, and in 1867 became the first company west of the Rocky Mountains in the United States to smelt iron. The company failed after a few years, but was reorganized as the Oswego Iron Company in 1878, and again as the Oregon Iron and Steel Company in 1883. With the addition of a larger furnace, the last incarnation of the company prospered, reaching peak production in 1890. By 1894, however, pressure from cheaper imported iron combined with the effects of the Panic of 1893 forced the company to close its smelter. The company continued to operate a pipe foundry until 1928, and until the early 1960s, existed as a land management company, selling its real estate holdings which expanded the city of Lake Oswego.

The Chester Rolling Mill was a large iron rolling mill established by shipbuilder John Roach in Chester, Pennsylvania, United States in 1873. The main purpose of the Mill was to provide metal hull plates, beams and other parts for the ships built at Roach's Delaware River Iron Ship Building and Engine Works, also located at Chester.

The Grubb Family Iron Dynasty was a succession of iron manufacturing enterprises owned and operated by Grubb family members for more than 165 years. Collectively, they were Pennsylvania's leading iron manufacturer between 1840 and 1870.

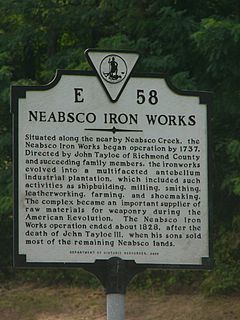

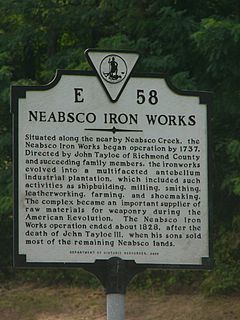

The Neabsco Iron Works was located in Woodbridge, Virginia, US. It was situated on 5,000 acres (2,000 ha) by the Neabsco Creek.

The Hunedoara steel works, formally ArcelorMittal Hunedoara and formerly the Hunedoara Ironworks, Hunedoara Steel Works, Siderurgica Hunedoara and Mittal Steel, is a steel mill in the Transylvanian city of Hunedoara, Romania.

The Fitzroy Iron Works at Mittagong, New South Wales, was the first commercial iron smelting works in Australia. It first operated in 1848.

The Iron and Steel Industry in Scunthorpe was established in the mid 19th century, following the discovery and exploitation of middle Lias ironstone east of Scunthorpe, Lincolnshire, England.

3D Model of Coal Kilns created by Chris Baker

The Low Moor Ironworks was a wrought iron foundry established in 1791 in the village of Low Moor about 3 miles (4.8 km) south of Bradford in Yorkshire, England. The works were built to exploit the high-quality iron ore and low-sulphur coal found in the area. Low Moor made wrought iron products from 1801 until 1957 for export around the world. At one time it was the largest ironworks in Yorkshire, a major complex of mines, piles of coal and ore, kilns, blast furnaces, forges and slag heaps connected by railway lines. The surrounding countryside was littered with waste, and smoke from the furnaces and machinery blackened the sky. Today Low Moor is still industrial, but the pollution has been mostly eliminated.

Iron Ore Hill is a Canadian rural community in Carleton County, New Brunswick, 5 kilometers northwest of Woodstock.

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to coke in ore smelting, adopted the Bessemer process, and saw the rise of very large integrated steel mills. In the 20th century, the US industry successively adopted the open hearth furnace, then the basic oxygen steelmaking process. Since the American industry peaked in the 1940s and 1950s, the US industry has shifted to small mini-mills and specialty mills, using iron and steel scrap as feedstock, rather than iron ore.

Lal Lal Iron Mine and Smelting Works were located close to the western branch of the Moorabool River, near the town of Lal Lal, Victoria, Australia, which lies on the Geelong-Ballarat railway line about 19 km from Ballarat. From 1875 to 1884, pig iron was made there in a blast furnace using iron ore mined at the site, locally produced charcoal, and limestone from a nearby deposit. The works ultimately proved to be uneconomic. It remains the only attempt to establish an iron smelting industry in Victoria.