Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other dross, which makes it brittle and not useful directly as a material except for limited applications.

Wrought iron is an iron alloy with a very low carbon content in contrast to that of cast iron. It is a semi-fused mass of iron with fibrous slag inclusions, which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically.

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-finished casting products are made from molten pig iron or from scrap.

An open-hearth furnace or open hearth furnace is any of several kinds of industrial furnace in which excess carbon and other impurities are burnt out of pig iron to produce steel. Because steel is difficult to manufacture owing to its high melting point, normal fuels and furnaces were insufficient for mass production of steel, and the open-hearth type of furnace was one of several technologies developed in the nineteenth century to overcome this difficulty. Compared with the Bessemer process, which it displaced, its main advantages were that it did not expose the steel to excessive nitrogen, was easier to control, and permitted the melting and refining of large amounts of scrap iron and steel.

Henry Cort was an English ironware producer who was formerly a Navy pay agent. During the Industrial Revolution in England, Cort began refining iron from pig iron to wrought iron using innovative production systems. In 1784, he obtained a patent for an improved version of Peter Onions's puddling process, for refining cast iron, although its commercial viability was only realised in the 1790s, through further innovations introduced by Richard Crawshay and Homfray of the Cyfarthfa Ironworks in Merthyr Tydfil.

The Iron Act, also called the Importation, etc. Act 1749, was an Act of the Parliament of Great Britain, which was one of the legislative measures introduced within the system of Trade and Navigation Acts. The Act sought to increase the importation of pig and bar iron from its American colonies and to prevent the building of iron-related production facilities within these colonies, particularly in North America where these raw materials were identified. The dual purpose of the Act was to increase manufacturing capacity within Great Britain itself, and to limit potential competition from the colonies possessing the raw materials.

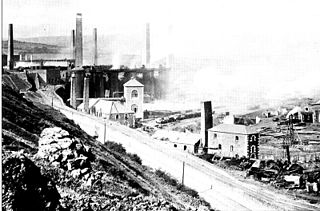

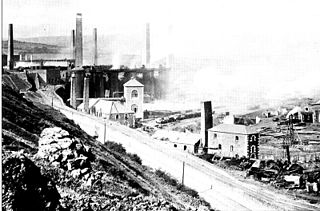

The Cyfarthfa Ironworks were major 18th- and 19th-century ironworks in Cyfarthfa, on the north-western edge of Merthyr Tydfil, in South West Wales.

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an oxidizing environment to burn the carbon, resulting in wrought iron. It was one of the most important processes for making the first appreciable volumes of valuable and useful bar iron without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels.

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery forges were used as early as the 3rd century BC in China. The finery forge process was replaced by the puddling process and the roller mill, both developed by Henry Cort in 1783–4, but not becoming widespread until after 1800.

JFE Steel is the second largest Japanese steel manufacturer. The company was created in 2002 through the merger of the steel manufacturing business of Kawasaki Steel and NKK. It is owned by JFE Holdings, which is listed on the Tokyo Stock Exchange.

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania iron producer from 1742 until it was shut down in 1883. The furnaces, support buildings and surrounding community have been preserved as a historical site and museum, providing a glimpse into Lebanon County's industrial past. The site is the only intact charcoal-burning iron blast furnace in its original plantation in the Western Hemisphere. Established by Peter Grubb in 1742, Cornwall Furnace was operated during the American Revolution by his sons Curtis and Peter Jr. who were major arms providers to George Washington. Robert Coleman acquired Cornwall Furnace after the Revolution and became Pennsylvania's first millionaire. Ownership of the furnace and its surroundings was transferred to the Commonwealth of Pennsylvania in 1932.

The Lancashire hearth was used to fine pig iron, removing carbon to produce wrought iron.

Ebbw Vale Steelworks was an integrated steel mill located in Ebbw Vale, South Wales. Developed from 1790, by the late 1930s it had become the largest steel mill in Europe. It was nationalised after World War II. As the steel industry changed to bulk handling, iron and steel making was ceased in the 1970s, and the site was redeveloped as a specialised tinplate works. It was closed by Corus in 2002, but is being redeveloped in a joint partnership between Blaenau Gwent Council and the Welsh Government.

The Fitzroy Iron Works at Mittagong, New South Wales, was the first commercial iron smelting works in Australia. It first operated in 1848.

The Yahata Steel Works is a steel mill in Kitakyūshū, Fukuoka Prefecture, Japan. Imperial Steel Works was established in 1896 to meet increasing demand from the nation's burgeoning shipbuilding, railway, construction, and armaments industries. The site chosen was the former town of Yahata, now merged into Kitakyūshū, near coal mines and with easy access to the sea.

Nippon Steel Corporation is Japan's largest steelmaker, headquartered in Marunouchi, Chiyoda, Tokyo. The company has four business segments, including steelmaking, engineering, chemicals, and system solutions. It is the largest producer of crude steel in Japan and the fourth largest in the world.

Kakogawa Steel Works is Kobe Steel, Ltd.'s ironworks in Kakogawa, Hyogo, Japan, established in 1969. It is responsible for about 80 percent of the company's iron and steel production.

Kimitsu Steel Works is an ironworks in Kimitsu, Chiba, Japan, established in 1965 by Nippon Steel Corporation, part of Nippon Steel & Sumitomo Metal Corporation after its 2012 merger with Sumitomo Metal Industries.

Fuji Iron & Steel was a major Japanese steel-producing company that existed from 1950 to 1970.