Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a specialized craft and a medium for artistic expression.

Newsprint is a low-cost, non-archival paper consisting mainly of wood pulp and most commonly used to print newspapers and other publications and advertising material. Invented in 1844 by Charles Fenerty of Nova Scotia, Canada, it usually has an off white cast and distinctive feel. It is designed for use in printing presses that employ a long web of paper, rather than individual sheets of paper.

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products.

A paper mill is a factory devoted to making paper from vegetable fibres such as wood pulp, old rags, and other ingredients. Prior to the invention and adoption of the Fourdrinier machine and other types of paper machine that use an endless belt, all paper in a paper mill was made by hand, one sheet at a time, by specialized laborers.

Bad Schandau is a spa town in Germany, in the Sächsische Schweiz-Osterzgebirge district of Saxony. It is situated on the right bank of the Elbe, at the mouth of the valley of the Kirnitzsch and in the area often described as Saxon Switzerland.

Charles Fenerty, was a Canadian inventor who invented the wood pulp process for papermaking, which was first adapted into the production of newsprint. Fenerty was also a poet.

Hainichen is a market town in Saxony, Germany. It is located on the river Kleine Striegis and about 15 miles north-east of Chemnitz. Hainichen has been shaped by its industrial past.

The Voith Group[fɔʏ̯t] is a German manufacturer of machines for the pulp and paper industry, technical equipment for hydropower plants and drive and braking systems. The family-owned company, which operates worldwide and has its headquarters in Heidenheim an der Brenz, was founded in 1867.

The sulfite process produces wood pulp that is almost pure cellulose fibers by treating wood chips with solutions of sulfite and bisulfite ions. These chemicals cleave the bonds between the cellulose and lignin components of the lignocellulose. A variety of sulfite/bisulfite salts are used, including sodium (Na+), calcium (Ca2+), potassium (K+), magnesium (Mg2+), and ammonium (NH4+). The lignin is converted to lignosulfonates, which are soluble and can be separated from the cellulose fibers. For the production of cellulose, the sulfite process competes with the Kraft process which produces stronger fibers and is less environmentally costly.

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distributed on the surface, followed by pressing and drying. Although paper was originally made in single sheets by hand, almost all is now made on large machines—some making reels 10 metres wide, running at 2,000 metres per minute and up to 600,000 tonnes a year. It is a versatile material with many uses, including printing, painting, graphics, signage, design, packaging, decorating, writing, and cleaning. It may also be used as filter paper, wallpaper, book endpaper, conservation paper, laminated worktops, toilet tissue, or currency and security paper, or in a number of industrial and construction processes.

Soda pulping is a chemical process for making wood pulp with sodium hydroxide as the cooking chemical. In the Soda-AQ process, anthraquinone (AQ) may be used as a pulping additive to decrease the carbohydrate degradation. The soda process gives pulp with lower tear strength than other chemical pulping processes, but has still limited use for easily-pulped materials like straw and some hardwoods.

Paper is a thin nonwoven material traditionally made from a combination of milled plant and textile fibres. The first paper-like plant-based writing sheet was papyrus in Egypt, but the first true paper, the first true papermaking process was documented in China during the Eastern Han period, traditionally attributed to the court official Cai Lun. This plant-puree conglomerate produced by pulp mills and paper mills was used for writing, drawing, and money. During the 8th century, Chinese paper making spread to the Islamic world, replacing papyrus. By the 11th century, papermaking was brought to Europe, where it replaced animal-skin-based parchment and wood panels. By the 13th century, papermaking was refined with paper mills using waterwheels in Spain. Later improvements to the papermaking process came in 19th century Europe with the invention of wood-based papers.

Carl Daniel Ekman was a Swedish chemical engineer who invented the form of the sulfite process of wood pulp manufacturing which was first established on a firm commercial basis, helping to replace rags as the main raw material of paper with wood pulp. The process was developed at Bergvik, Sweden from 1871–1874, In 1879, he emigrated to England, and opened the Ekman Pulp and Paper Company mill in Northfleet, Kent near the mouth of the Thames River in 1886. He was also a consulting engineer and helped establish mills in Lachendorf, Celle, Germany, Dieppe, France, Rumford, Rhode Island, St. Petersburg, Russia, Corfu and Italy. After contracting malaria in French Guiana and losing a lawsuit on pollution of a Northfleet limestone quarry, he died bankrupt in Gravesend, Kent.

Nicolas Louis Robert was a French soldier and mechanical engineer, who is credited with a paper-making invention that became the blueprint of the Fourdrinier machine.

Heinrich Voelter was a German inventor and paper manufacturer.

The History of Papermaking in New York had its beginnings in the late 18th century, at a time when linen and cotton rags were the primary source of fibers in the manufacturing process. By 1850 there were more than 106 paper mills in New York, more than in any other state. A landmark in the history of papermaking in the United States was the installation of the first Fourdrinier machine in the country at a mill in Saugerties, New York, in 1827. Papermaking from ground-wood pulp began in New York in 1869, with the establishment of the Hudson River Pulp & Paper Company in Corinth and also with the work of Illustrious Remington and his sons in Watertown. The innovation and success of the Remingtons spurred further development of the industry in the state.

This article addresses the history of papermaking in Massachusetts.

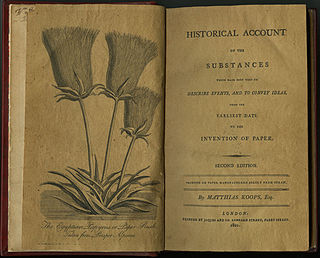

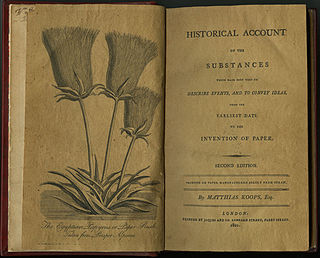

Matthias Koops was a British paper-maker who invented the first practical processes for manufacturing paper from wood pulp, straw, or recycled waste paper, without the necessity of including expensive linen or cotton rags.

Friedrich Keller may refer to:

Hemp paper is paper varieties consisting exclusively or to a large extent from pulp obtained from fibers of industrial hemp. The products are mainly specialty papers such as cigarette paper, banknotes and technical filter papers. Compared to wood pulp, hemp pulp offers a four to five times longer fibre, a significantly lower lignin fraction as well as a higher tear resistance and tensile strength. Because the paper industry's processes have been optimized for wood as the feedstock, production costs currently are much higher than for paper from wood.