Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

HVAC equipment needs a control system to regulate the operation of a heating and/or air conditioning system. Usually a sensing device is used to compare the actual state with a target state. Then the control system draws a conclusion what action has to be taken.

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

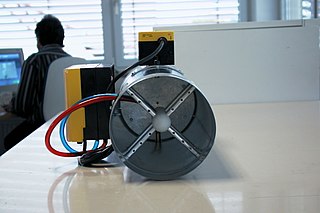

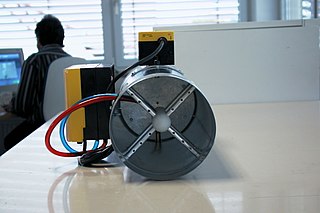

A damper is a valve or plate that stops or regulates the flow of air inside a duct, chimney, VAV box, air handler, or other air-handling equipment. A damper may be used to cut off central air conditioning to an unused room, or to regulate it for room-by-room temperature and climate control - for example, in the case of Volume Control Dampers. Its operation can be manual or automatic. Manual dampers are turned by a handle on the outside of a duct. Automatic dampers are used to regulate airflow constantly and are operated by electric or pneumatic motors, in turn controlled by a thermostat or building automation system. Automatic or motorized dampers may also be controlled by a solenoid, and the degree of air-flow calibrated, perhaps according to signals from the thermostat going to the actuator of the damper in order to modulate the flow of air-conditioned air in order to effect climate control.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, furnace or A/C elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU, sometimes exhausting air to the atmosphere and bringing in fresh air. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

A forced-air central heating system is one which uses air as its heat transfer medium. These systems rely on ductwork, vents, and plenums as means of air distribution, separate from the actual heating and air conditioning systems. The return plenum carries the air from several large return grills (vents) to a central air handler for re-heating. The supply plenum directs air from the central unit to the rooms which the system is designed to heat. Regardless of type, all air handlers consist of an air filter, blower, heat exchanger/element/coil, and various controls. Like any other kind of central heating system, thermostats are used to control forced air heating systems.

Variable air volume (VAV) is a type of heating, ventilating, and/or air-conditioning (HVAC) system. Unlike constant air volume (CAV) systems, which supply a constant airflow at a variable temperature, VAV systems vary the airflow at a constant or varying temperature. The advantages of VAV systems over constant-volume systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, less fan noise, and additional passive dehumidification.

Forced-air gas heating systems are used in central air heating/cooling systems for houses. Sometimes the system is referred to as "forced hot air".

Ducts are conduits or passages used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air. The needed airflows include, for example, supply air, return air, and exhaust air. Ducts commonly also deliver ventilation air as part of the supply air. As such, air ducts are one method of ensuring acceptable indoor air quality as well as thermal comfort.

Air conditioning, often abbreviated as A/C (US) or air con (UK), is the process of removing heat from an enclosed space to achieve a more comfortable interior environment and in some cases also strictly controlling the humidity of internal air. Air conditioning can be achieved using a mechanical 'air conditioner' or alternatively a variety of other methods, including passive cooling and ventilative cooling. Air conditioning is a member of a family of systems and techniques that provide heating, ventilation, and air conditioning (HVAC). Heat pumps are similar in many ways to air conditioners, but use a reversing valve to allow them both to heat and to cool an enclosed space.

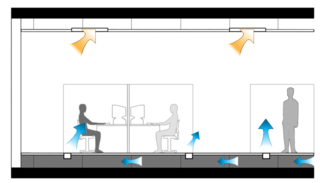

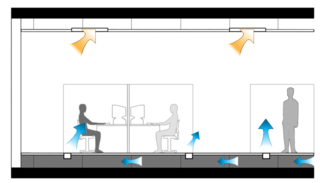

Room air distribution is characterizing how air is introduced to, flows through, and is removed from spaces. HVAC airflow in spaces generally can be classified by two different types: mixing and displacement.

A fan coil unit (FCU), also known as a Vertical Fan Coil-Unit (VFC), is a device consisting of a heat exchanger (coil) and a fan. FCUs are commonly used in HVAC systems of residential, commercial, and industrial buildings that use ducted split air conditioning or with central plant cooling. FCUs are typically connected to ductwork and a thermostat to regulate the temperature of one or more spaces and to assist the main air handling unit for each space if used with chillers. The thermostat controls the fan speed and/or the flow of water or refrigerant to the heat exchanger using a control valve.

Fire dampers are passive fire protection products used in heating, ventilation, and air conditioning (HVAC) ducts to prevent and isolate the spread of fire inside the ductwork through fire-resistance rated walls and floors. Fire/smoke dampers are similar to fire dampers in fire resistance rating, and also prevent the spread of smoke inside the ducts. When a rise in temperature occurs, the fire damper closes, usually activated by a thermal element which melts at temperatures higher than ambient but low enough to indicate the presence of a fire, allowing springs to close the damper blades. Fire dampers can also close following receipt of an electrical signal from a fire alarm system utilising detectors remote from the damper, indicating the sensing of heat or smoke in the building occupied spaces or in the HVAC duct system.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

Thermal destratification is the process of mixing the internal air in a building to eliminate stratified layers and achieve temperature equalization throughout the building envelope.

Underfloor air distribution (UFAD) is an air distribution strategy for providing ventilation and space conditioning in buildings as part of the design of a HVAC system. UFAD systems use an underfloor supply plenum located between the structural concrete slab and a raised floor system to supply conditioned air to supply outlets, located at or near floor level within the occupied space. Air returns from the room at ceiling level or the maximum allowable height above the occupied zone.

In building services engineering and HVAC, an air-mixing plenum is used for mixing air from different ductwork systems.

A grille or grill is an opening of several slits side-by-side in a wall, metal sheet or another barrier, usually to allow air or water to enter and/or leave and prevent larger objects from going in or out.