Related Research Articles

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Silicon carbide (SiC), also known as carborundum, is a semiconductor containing silicon and carbon. It occurs in nature as the extremely rare mineral moissanite. Synthetic SiC powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Large single crystals of silicon carbide can be grown by the Lely method and they can be cut into gems known as synthetic moissanite.

Presolar grains are interstellar solid matter in the form of tiny solid grains that originated at a time before the Sun was formed. Presolar stardust grains formed within outflowing and cooling gases from earlier presolar stars.

A cermet is a composite material composed of ceramic (cer) and metal (met) materials.

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and wear resistance. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining.

Titanium carbide, TiC, is an extremely hard refractory ceramic material, similar to tungsten carbide. It has the appearance of black powder with the sodium chloride crystal structure.

Titanium nitride is an extremely hard ceramic material, often used as a coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface properties.

Silicon nitride is a chemical compound of the elements silicon and nitrogen. Si

3N

4 is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot H

2SO

4. It is very hard. It has a high thermal stability with strong optical nonlinearities for all-optical applications.

Aluminum carbide, chemical formula Al4C3, is a carbide of aluminum. It has the appearance of pale yellow to brown crystals. It is stable up to 1400 °C. It decomposes in water with the production of methane.

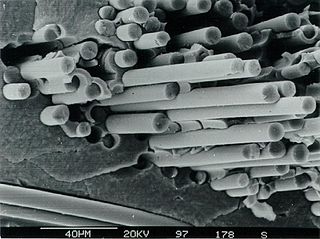

Chemical vapour infiltration (CVI) is a ceramic engineering process whereby matrix material is infiltrated into fibrous preforms by the use of reactive gases at elevated temperature to form fiber-reinforced composites. The earliest use of CVI was the infiltration of fibrous alumina with chromium carbide. CVI can be applied to the production of carbon-carbon composites and ceramic-matrix composites. A similar technique is chemical vapour deposition (CVD), the main difference being that the deposition of CVD is on hot bulk surfaces, while CVI deposition is on porous substrates.

Zirconium diboride (ZrB2) is a highly covalent refractory ceramic material with a hexagonal crystal structure. ZrB2 is an ultra high temperature ceramic (UHTC) with a melting point of 3246 °C. This along with its relatively low density of ~6.09 g/cm3 (measured density may be higher due to hafnium impurities) and good high temperature strength makes it a candidate for high temperature aerospace applications such as hypersonic flight or rocket propulsion systems. It is an unusual ceramic, having relatively high thermal and electrical conductivities, properties it shares with isostructural titanium diboride and hafnium diboride.

Aluminum magnesium boride or Al3Mg3B56 colliqually known as BAM is a chemical compound of aluminium, magnesium and boron. Whereas its nominal formula is AlMgB14, the chemical composition is closer to Al0.75Mg0.75B14. It is a ceramic alloy that is highly resistive to wear and has an extremely low coefficient of sliding friction, reaching a record value of 0.04 in unlubricated and 0.02 in lubricated AlMgB14−TiB2 composites. First reported in 1970, BAM has an orthorhombic structure with four icosahedral B12 units per unit cell. This ultrahard material has a coefficient of thermal expansion comparable to that of other widely used materials such as steel and concrete.

Ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, whereby carbon and carbon fibers can also be regarded as a ceramic material.

Carbide-derived carbon (CDC), also known as tunable nanoporous carbon, is the common term for carbon materials derived from carbide precursors, such as binary (e.g. SiC, TiC), or ternary carbides, also known as MAX phases (e.g., Ti2AlC, Ti3SiC2). CDCs have also been derived from polymer-derived ceramics such as Si-O-C or Ti-C, and carbonitrides, such as Si-N-C. CDCs can occur in various structures, ranging from amorphous to crystalline carbon, from sp2- to sp3-bonded, and from highly porous to fully dense. Among others, the following carbon structures have been derived from carbide precursors: micro- and mesoporous carbon, amorphous carbon, carbon nanotubes, onion-like carbon, nanocrystalline diamond, graphene, and graphite. Among carbon materials, microporous CDCs exhibit some of the highest reported specific surface areas (up to more than 3000 m2/g). By varying the type of the precursor and the CDC synthesis conditions, microporous and mesoporous structures with controllable average pore size and pore size distributions can be produced. Depending on the precursor and the synthesis conditions, the average pore size control can be applied at sub-Angstrom accuracy. This ability to precisely tune the size and shapes of pores makes CDCs attractive for selective sorption and storage of liquids and gases (e.g., hydrogen, methane, CO2) and the high electric conductivity and electrochemical stability allows these structures to be effectively implemented in electrical energy storage and capacitive water desalinization.

Titanium aluminium nitride (TiAlN) or aluminium titanium nitride is a group of metastable hard coatings consisting of nitrogen and the metallic elements aluminium and titanium. Four important compositions are deposited in industrial scale by physical vapor deposition methods:

The MAX phases are layered, hexagonal carbides and nitrides which have the general formula: Mn+1AXn, (MAX) where n = 1 to 3, and M is an early transition metal, A is an A-group (mostly IIIA and IVA, or groups 13 and 14) element and X is either carbon and/or nitrogen. The layered structure consists of edge-sharing, distorted XM6 octahedra interleaved by single planar layers of the A-group element.

Ultra-high-temperature ceramics (UHTCs) are a class of refractory ceramics that offer excellent stability at temperatures exceeding 2000 °C being investigated as possible thermal protection system (TPS) materials, coatings for materials subjected to high temperatures, and bulk materials for heating elements. Broadly speaking, UHTCs are borides, carbides, nitrides, and oxides of early transition metals. Current efforts have focused on heavy, early transition metal borides such as hafnium diboride (HfB2) and zirconium diboride (ZrB2); additional UHTCs under investigation for TPS applications include hafnium nitride (HfN), zirconium nitride (ZrN), titanium carbide (TiC), titanium nitride (TiN), thorium dioxide (ThO2), tantalum carbide (TaC) and their associated composites.

Abnormal or discontinuous grain growth, also referred to as exaggerated or secondary recrystallisation grain growth, is a grain growth phenomenon through which certain energetically favorable grains (crystallites) grow rapidly in a matrix of finer grains resulting in a bimodal grain size distribution.

In materials science, MXenes are a class of two-dimensional inorganic compounds. These materials consist of a-few-atoms-thick layers of transition metal carbides, nitrides, or carbonitrides. First described in 2011, MXenes combine the metallic conductivity of transition metal carbides with a hydrophilic nature because of their hydroxyl- or oxygen-terminated surfaces.

Silicide carbides or carbide silicides are compounds containing anions composed of silicide (Si4−) and carbide (C4−) or clusters therof. They can be considered as mixed anion compounds or intermetallic compounds, as silicon could be considered as a semimetal.

References

- ↑ Zhou, Y; Sun, Z; Sun, J (April 2000). "Titanium silicon carbide: a ceramic or a metal?". Zeitschrift für Metallkunde. 91 (4): 329–334.

- ↑ "Titanium Silicocarbide ( Ti3SiC2 ) Titanium Silcon Carbide - Properties and Applications". AZoM.com. 2004-02-05. Retrieved 2018-05-17.