In physics, cryogenics is the production and behaviour of materials at very low temperatures.

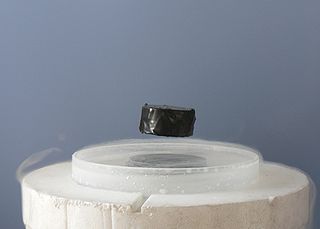

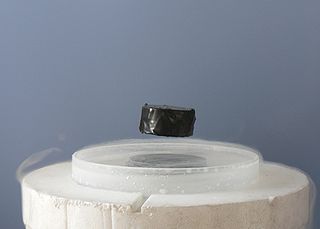

Superconductivity is a set of physical properties observed in certain materials where electrical resistance vanishes and magnetic flux fields are expelled from the material. Any material exhibiting these properties is a superconductor. Unlike an ordinary metallic conductor, whose resistance decreases gradually as its temperature is lowered, even down to near absolute zero, a superconductor has a characteristic critical temperature below which the resistance drops abruptly to zero. An electric current through a loop of superconducting wire can persist indefinitely with no power source.

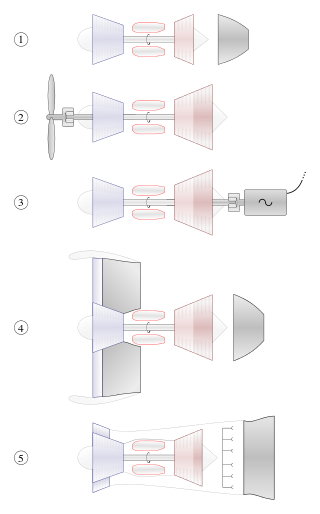

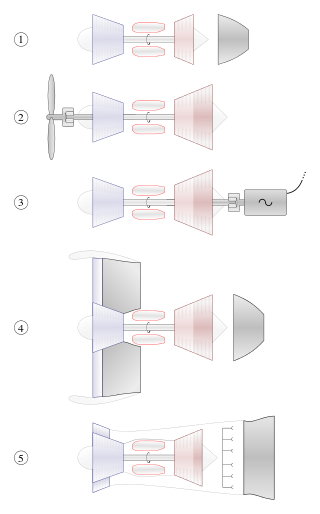

A turbine is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmills and waterwheels.

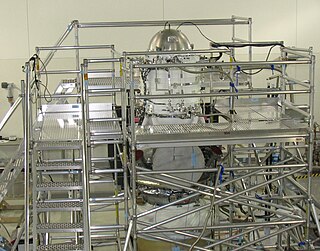

A turbopump is a propellant pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft, or sometimes geared together. They were initially developed in Germany in the early 1940s. The purpose of a turbopump is to produce a high-pressure fluid for feeding a combustion chamber or other use.

A linear motor is an electric motor that has had its stator and rotor "unrolled", thus, instead of producing a torque (rotation), it produces a linear force along its length. However, linear motors are not necessarily straight. Characteristically, a linear motor's active section has ends, whereas more conventional motors are arranged as a continuous loop.

Some of the technological applications of superconductivity include:

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

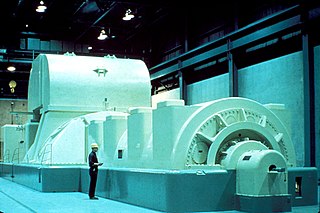

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy.

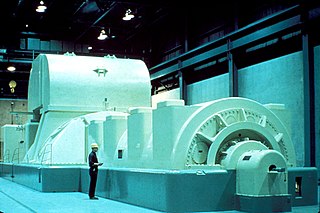

In electricity generation, a generator is a device that converts motive power or fuel-based power into electric power for use in an external circuit. Sources of mechanical energy include steam turbines, gas turbines, water turbines, internal combustion engines, wind turbines and even hand cranks. The first electromagnetic generator, the Faraday disk, was invented in 1831 by British scientist Michael Faraday. Generators provide nearly all of the power for electric power grids.

High-temperature superconductors are defined as materials that behave as superconductors at temperatures above 77 K, the boiling point of liquid nitrogen. The adjective "high temperature" is only in respect to previously known superconductors, which function at even colder temperatures close to absolute zero. In absolute terms, these "high temperatures" are still far below ambient, and therefore require cooling. The first high-temperature superconductor was discovered in 1986, by IBM researchers Bednorz and Müller, who were awarded the Nobel Prize in Physics in 1987 "for their important break-through in the discovery of superconductivity in ceramic materials". Most high-Tc materials are type-II superconductors.

A superconducting magnet is an electromagnet made from coils of superconducting wire. They must be cooled to cryogenic temperatures during operation. In its superconducting state the wire has no electrical resistance and therefore can conduct much larger electric currents than ordinary wire, creating intense magnetic fields. Superconducting magnets can produce stronger magnetic fields than all but the strongest non-superconducting electromagnets, and large superconducting magnets can be cheaper to operate because no energy is dissipated as heat in the windings. They are used in MRI instruments in hospitals, and in scientific equipment such as NMR spectrometers, mass spectrometers, fusion reactors and particle accelerators. They are also used for levitation, guidance and propulsion in a magnetic levitation (maglev) railway system being constructed in Japan.

A DC motor is any of a class of rotary electrical motors that converts direct current (DC) electrical energy into mechanical energy. The most common types rely on the forces produced by induced magnetic fields due to flowing current in the coil. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor.

A cryostat is a device used to maintain low cryogenic temperatures of samples or devices mounted within the cryostat. Low temperatures may be maintained within a cryostat by using various refrigeration methods, most commonly using cryogenic fluid bath such as liquid helium. Hence it is usually assembled into a vessel, similar in construction to a vacuum flask or Dewar. Cryostats have numerous applications within science, engineering, and medicine.

American Superconductor (AMSC) is an American energy technologies company based in Ayer, Massachusetts specializing in the design and manufacture of power systems and superconducting wire. It owns AMSC Windtech in Klagenfurt, Austria.

Doubly-fed electric machines also slip-ring generators are electric motors or electric generators, where both the field magnet windings and armature windings are separately connected to equipment outside the machine.

In electrical engineering, electric machine is a general term for machines using electromagnetic forces, such as electric motors, electric generators, and others. They are electromechanical energy converters: an electric motor converts electricity to mechanical power while an electric generator converts mechanical power to electricity. The moving parts in a machine can be rotating or linear. Besides motors and generators, a third category often included is transformers, which although they do not have any moving parts are also energy converters, changing the voltage level of an alternating current.

Superconductors can be classified in accordance with several criteria that depend on physical properties, current understanding, and the expense of cooling them or their material.

Jarl-Thure Eriksson is Doctor of Science in Technology, Professor of Electrical Engineering and Rector of Tampere University of Technology (TUT) in Finland between the years 1997–2008. During Eriksson's period as rector, the university expanded vigorously and its scientific publishing activity amplified. Due to his scientific merits, Eriksson has been a member of the Finnish Academy of Technology since 1989 and of the Swedish Academy of Engineering Sciences in Finland since 1997. His perhaps most significant position of trust outside the university is membership in the Governing Board of the Millennium Prize Foundation since 2003. He is currently Chancellor of Åbo Akademi University in Turku, Finland.

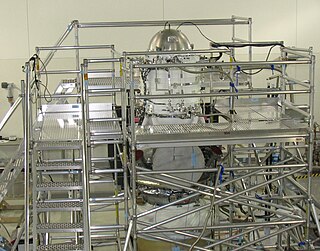

The NASA Electric Aircraft Testbed (NEAT) is a NASA reconfigurable testbed in Plum Brook Station, Ohio, used to design, develop, assemble and test electric aircraft power systems, from a small, one or two person aircraft up to 20 MW (27,000 hp) airliners. NASA research agreements (NRA) are granted to develop electric-propulsion components. They will be completed in 2019 and the internal NASA work by 2020, then they will be assembled in a megawatt-scale drive system to be tested in the narrowbody-sized NEAT.

Hydrogen cryomagnetics is a term used to denote the use of cryogenic liquid hydrogen to cool the windings of an electromagnet. A key benefit of hydrogen cryomagnetics is that low temperature liquid hydrogen can be deployed simultaneously both as a cryogen to cool electromagnet windings and as an energy carrier. That is, powerful synergistic benefits are likely to arise when hydrogen is used as a fuel and as a coolant. Even without the fuel/coolant synergies, hydrogen cryomagnetics is an attractive option for the cooling of superconducting electromagnets as it eliminates dependence upon increasingly scarce and expensive liquid helium. For hydrogen cryomagnetic applications specialist hydrogen-cooled electromagnets are wound using either copper or superconductors. Liquid-hydrogen-cooled copper-wound magnets work well as pulsed field magnets. Superconductors have the property that they can operate continuously and very efficiently as electrical resistive losses are almost entirely avoided. Most commonly the term "hydrogen cryomagnetics" is used to denote the use of cryogenic liquid hydrogen directly, or indirectly, to enable high temperature superconductivity in electromagnet windings.