ASTM C 1349 is a Standard Specification for Architectural Flat Glass Clad Polycarbonate. This specification was created by the American Society for Testing and Materials (ASTM). Founded in 1898, ASTM International is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This specification deals with the quality requirements for cut sizes of glass clad polycarbonate (GCP). Polycarbonate is becoming more common in house wares as well as laboratories and in industry, especially in applications where any of its main features — high impact resistance, temperature resistance, optical properties—are required. In this regards, polycarbonate is useful regarding security, detention, hurricane/cyclic wind-resistant, and blast and ballistic-resistant glazing applications.

International standards are technical standards developed by international standards organizations. International standards are available for consideration and use worldwide. The most prominent organization is the International Organization for Standardization (ISO).

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Some 12,575 ASTM voluntary consensus standards operate globally. The organization's headquarters is in West Conshohocken, Pennsylvania, about 5 mi (8.0 km) northwest of Philadelphia.

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list.

The main keywords to present this specification are: edge compression; flat glass; heat-strengthened glass; heat-treated glass; surface compression; tempered glass.

A thermoplastic, or thermosoftening plastic, is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

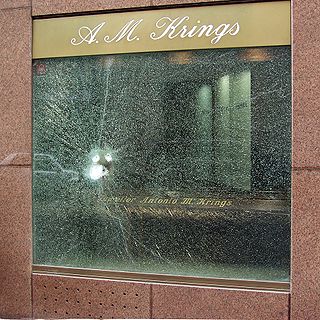

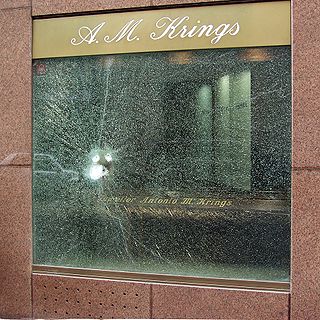

Bulletproof glass is a type of strong, but optically transparent, material that is particularly resistant to being penetrated when struck. Like any material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so it can flex instead of shatter. The index of refraction for both of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3 1⁄2 inches.

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion, making them resistant to thermal shock, more so than any other common glass. Such glass is less subject to thermal stress and is commonly used for the construction of reagent bottles. Borosilicate glass is sold under such trade names as Borcam, Borosil, DURAN, Suprax, Simax, BSA 60, BSC 51, Heatex, Endural, Schott, Refmex, Kimble, MG(India) and some items sold under different trade names.

The SAE steel grades system is a standard alloy numbering systems for steel grades maintained by SAE International.

ASTM A53 is a carbon steel alloy, used as structural steel or for low-pressure plumbing. The alloy specifications are set by ASTM International, in specification ASTM A53/A53M.

6061 is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminum for general-purpose use.

ASTM E 2395 is a Standard Specification for Voluntary Security Performance of Window and Door Assemblies with and without Glazing Impact. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was funded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. Through this standard is specified voluntary performance test for the resistance to forced entry of window and door assemblies. This standards deal with the capability of window and door assemblies to prevent entry about intruders. These requirements are only limited to window and door assemblies

ASTM is a standard specification for steel chain-link fencing materials used for high security applications. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was funded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This was published by ASTM F14 which is a committee specializes about high security fences and perimeter barriers.

ASTM F 2248 is a standard practice for specifying an equivalent 3-Second Duration design loading for blast resistant glazing fabricated with laminated glass. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was funded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This standard was published by ASTM F14 which is a committee specializes about on systems products and services. The standard explain different methods to check the thickness and type of blast resistant glazing fabricated with laminated glass to glaze a fenestration

ASTM F 2348 is a standard test performance specification for privacy padlocks. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was funded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This standard was published by ASTM F12.50 which is a committee specializes about locking devices. The standards deal with requirement regarding security for padlocks. This standard involves descriptions, operational tests, forcing tests, and surreptitious entry tests.

ASTM F626 is a standard specification for fence fittings.

ASTM F 883 is a standard performance specification for padlocks.

Bituminous waterproofing systems are designed to protect residential and commercial buildings. Bitumen is a mixed substance made up of organic liquids that are highly sticky, viscous, and waterproof. These systems are sometimes used to construct roofs, in the form of roofing felt or roll roofing products.

ASTM A325 is an ASTM International standard for heavy hex structural bolts, titled Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength. It defines mechanical properties for bolts that range from 1⁄2 to 1 1⁄2 inches in diameter.

ASTM A490 and ASTM A490M are ASTM International standards for heavy hex structural bolts made from alloy steel. The imperial standard is officially titled Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile Strength, while the metric standard (M) is titled Standard Specification for High-Strength Steel Bolts, Classes 10.9 and 10.9.3, for Structural Steel Joints.

Puncture resistance denotes the relative ability of a material or object to inhibit the intrusion of a foreign object. This is defined by a test method, regulation, or technical specification. It can be measured in several ways ranging from a slow controlled puncture to a rapid impact of a sharp object or a rounded probe.

Package testing or packaging testing involves the measurement of a characteristic or property involved with packaging. This includes packaging materials, packaging components, primary packages, shipping containers, and unit loads, as well as the associated processes.

2219 aluminium alloy is an alloy in the wrought aluminium-copper family. It can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys have high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys. To compensate for the lower corrosion resistance, 2219 aluminium can be clad in a commercially pure alloy such as 1050 or painted. This alloy is commonly formed by both extrusion and forging, but is not used in casting.