Related Research Articles

MEMS is the technology of microscopic devices incorporating both electronic and moving parts. MEMS are made up of components between 1 and 100 micrometres in size, and MEMS devices generally range in size from 20 micrometres to a millimetre, although components arranged in arrays can be more than 1000 mm2. They usually consist of a central unit that processes data and several components that interact with the surroundings.

Aqua regia is a mixture of nitric acid and hydrochloric acid, optimally in a molar ratio of 1:3. Aqua regia is a fuming liquid. Freshly prepared aqua regia is colorless, but it turns yellow, orange or red within seconds from the formation of nitrosyl chloride and nitrogen dioxide. It was so named by alchemists because it can dissolve noble metals like gold and platinum, though not all metals.

In semiconductor manufacturing, isotropic etching is a method commonly used to remove material from a substrate via a chemical process using an etchant substance. The etchant may be in liquid-, gas- or plasma-phase, although liquid etchants such as buffered hydrofluoric acid (BHF) for silicon dioxide etching are more often used. Unlike anisotropic etching, isotropic etching does not etch in a single direction, but rather etches in multiple directions within the substrate. Any horizontal component of the etch direction may therefore result in undercutting of patterned areas, and significant changes to device characteristics. Isotropic etching may occur unavoidably, or it may be desirable for process reasons.

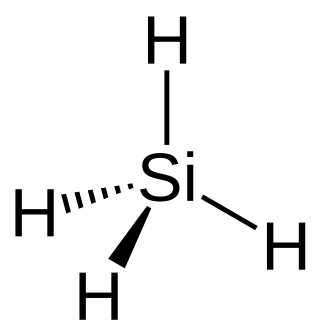

Silane (Silicane) is an inorganic compound with chemical formula SiH4. It is a colorless, pyrophoric, toxic gas with a sharp, repulsive, pungent smell, somewhat similar to that of acetic acid. Silane is of practical interest as a precursor to elemental silicon. Silane with alkyl groups are effective water repellents for mineral surfaces such as concrete and masonry. Silanes with both organic and inorganic attachments are used as coupling agents. They are commonly used to apply coatings to surfaces or as an adhesion promoter.

Tungsten(VI) fluoride, also known as tungsten hexafluoride, is an inorganic compound with the formula WF6. It is a toxic, corrosive, colorless gas, with a density of about 13 kg/m3 (22 lb/cu yd). It is the only known gaseous transition metal compound and the densest known gas under standard ambient temperature and pressure. WF6 is commonly used by the semiconductor industry to form tungsten films, through the process of chemical vapor deposition. This layer is used in a low-resistivity metallic "interconnect". It is one of seventeen known binary hexafluorides.

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and wear resistance. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining.

Neodymium(III) chloride or neodymium trichloride is a chemical compound of neodymium and chlorine with the formula NdCl3. This anhydrous compound is a mauve-colored solid that rapidly absorbs water on exposure to air to form a purple-colored hexahydrate, NdCl3·6H2O. Neodymium(III) chloride is produced from minerals monazite and bastnäsite using a complex multistage extraction process. The chloride has several important applications as an intermediate chemical for production of neodymium metal and neodymium-based lasers and optical fibers. Other applications include a catalyst in organic synthesis and in decomposition of waste water contamination, corrosion protection of aluminium and its alloys, and fluorescent labeling of organic molecules (DNA).

A single-displacement reaction, also known as single replacement reaction or exchange reaction, is an archaic concept in chemistry. It describes the stoichiometry of some chemical reactions in which one element or ligand is replaced by atom or group.

Ammonium fluoride is the inorganic compound with the formula NH4F. It crystallizes as small colourless prisms, having a sharp saline taste, and is highly soluble in water. Like all fluoride salts, it is moderately toxic in both acute and chronic overdose.

Porous silicon is a form of the chemical element silicon that has introduced nanopores in its microstructure, rendering a large surface to volume ratio in the order of 500 m2/cm3.

Hexafluorosilicic acid is an inorganic compound with the chemical formula H

2SiF

6. Aqueous solutions of hexafluorosilicic acid consist of salts of the cation and hexafluorosilicate anion. These salts and their aqueous solutions are colorless.

Xenon difluoride is a powerful fluorinating agent with the chemical formula XeF

2, and one of the most stable xenon compounds. Like most covalent inorganic fluorides it is moisture-sensitive. It decomposes on contact with water vapor, but is otherwise stable in storage. Xenon difluoride is a dense, colourless crystalline solid.

Tetramethylammonium hydroxide (TMAH or TMAOH) is a quaternary ammonium salt with molecular formula N(CH3)4+ OH−. It is commonly encountered in form of concentrated solutions in water or methanol. TMAH in solid state and its aqueous solutions are all colorless, but may be yellowish if impure. Although TMAH has virtually no odor when pure, samples often have a strong fishy smell due to presence of trimethylamine which is a common impurity. TMAH has several diverse industrial and research applications.

The bifluoride ion is an inorganic anion with the chemical formula [HF2]−. The anion is colorless. Salts of bifluoride are commonly encountered in the reactions of fluoride salts with hydrofluoric acid. The commercial production of fluorine involves electrolysis of bifluoride salts.

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module in fabrication, and every wafer undergoes many etching steps before it is complete.

Photochemical machining (PCM), also known as photochemical milling or photo etching, is a chemical milling process used to fabricate sheet metal components using a photoresist and etchants to corrosively machine away selected areas. This process emerged in the 1960s as an offshoot of the printed circuit board industry. Photo etching can produce highly complex parts with very fine detail accurately and economically.

The Wright etch is a preferential etch for revealing defects in <100>- and <111>-oriented, p- and n-type silicon wafers used for making transistors, microprocessors, memories, and other components. Revealing, identifying, and remedying such defects is essential for progress along the path predicted by Moore's law. It was developed by Margaret Wright Jenkins (1936-2018) in 1976 while working in research and development at Motorola Inc. in Phoenix, AZ. It was published in 1977. This etchant reveals clearly defined oxidation-induced stacking faults, dislocations, swirls and striations with minimum surface roughness or extraneous pitting. These defects are known causes of shorts and current leakage in finished semiconductor devices should they fall across isolated junctions. A relatively low etch rate at room temperature provides etch control. The long shelf life of this etchant allows the solution to be stored in large quantities.

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching include photo etching, chemical etching, photo chemical etching and photochemical machining. It is mostly used on metals, though other materials are increasingly important. It was developed from armor-decorating and printing etching processes developed during the Renaissance as alternatives to engraving on metal. The process essentially involves bathing the cutting areas in a corrosive chemical known as an etchant, which reacts with the material in the area to be cut and causes the solid material to be dissolved; inert substances known as maskants are used to protect specific areas of the material as resists.

Titanium adhesive bonding is an engineering process used in the aerospace industry, medical-device manufacture and elsewhere. Titanium alloy is often used in medical and military applications because of its strength, weight, and corrosion resistance characteristics. In implantable medical devices, titanium is used because of its biocompatibility and its passive, stable oxide layer. Also, titanium allergies are rare and in those cases mitigations like Parylene coating are used. In the aerospace industry titanium is often bonded to save cost, touch times, and the need for mechanical fasteners. In the past, Russian submarines' hulls were completely made of titanium because the non-magnetic nature of the material went undetected by the defense technology at that time. Bonding adhesive to titanium requires preparing the surface beforehand, and there is not a single solution for all applications. For example, etchant and chemical methods are not biocompatible and cannot be employed when the device will come into contact with blood and tissue. Mechanical surface roughness techniques like sanding and laser roughening may make the surface brittle and create micro-hardness regions that would not be suitable for cyclic loading found in military applications. Air oxidation at high temperatures will produce a crystalline oxide layer at a lower investment cost, but the increased temperatures can deform precision parts. The type of adhesive, thermosetting or thermoplastic, and curing methods are also factors in titanium bonding because of the adhesive's interaction with the treated oxide layer. Surface treatments can also be combined. For example, a grit blast process can be followed by a chemical etch and a primer application.

Vapor etching refers to a process used in the fabrication of Microelectromechanical systems (MEMS) and Nanoelectromechanical systems (NEMS). Sacrificial layers are isotropically etched using gaseous acids such as Hydrogen fluoride and Xenon difluoride to release the free standing components of the device.

References

- 1 2 Wolf, Stanley; Tauber, Richard (1986). Silicon Processing for the VLSI Era: Volume 1 - Process Technology. pp. 532–533. ISBN 978-0-9616721-3-3.

- ↑ Williams, K.R.; Muller, R.S. (Dec 1996). "Etch rates for micromachining processing". Journal of Microelectromechanical Systems. 5 (4): 256–269. doi:10.1109/84.546406.

- ↑ Iliescua, Ciprian; Jing, Ji; Tay, Francis; Miao, Jianmin; Sun, Tietun (Aug 2005). "Characterization of masking layers for deep wet etching of glass in an improved HF/HCl solution". J. Surf. Coat. 198 (1–3): 314. doi:10.1016/j.surfcoat.2004.10.094.

- ↑ "Buffered Oxide Etch" (PDF). Integrated Nanosystems Research Facility. UC Irvine. Retrieved 18 September 2024.

- ↑ Dumbre, Jayshri; Tong, Zherui; Dong, Dashen; Qiu, Dong; Easton, Mark (10 June 2024). "Buffered Oxide Etch: A Safer, More Effective Etchant for Additively Manufactured Ti-Alloys". Metallography, Microstructure, and Analysis. doi:10.1007/s13632-024-01094-x . Retrieved 18 September 2024.

- ↑ Qin, Z.; et al. (23 July 2013). "Chemical Equilibrium Controlled Etching of MFI-Type Zeolite and Its Influence on Zeolite Structure, Acidity, and Catalytic Activity". Chemistry of Materials. 25 (14): 2759–2766. doi:10.1021/cm400719z . Retrieved 18 September 2024.