Austria-Hungary, also referred to as the Austro-Hungarian Empire, the Dual Monarchy or the Habsburg Monarchy, was a multi-national constitutional monarchy in Central Europe between 1867 and 1918. A military and diplomatic alliance, it consisted of two sovereign states with a single monarch who was titled both Emperor of Austria and King of Hungary. Austria-Hungary constituted the last phase in the constitutional evolution of the Habsburg monarchy: it was formed with the Austro-Hungarian Compromise of 1867 in the aftermath of the Austro-Prussian War, following wars of independence by Hungary in opposition to Habsburg rule. It was dissolved shortly after Hungary terminated the union with Austria in 1918.

Ottó Titusz Bláthy was a Hungarian electrical engineer. During his career he became the co-inventor of the modern electric transformer, the voltage regulator, the AC watt-hour meter, the turbo generator, the high-efficiency turbo generator and the motor capacitor for the single-phase (AC) electric motor.

The Austro-Hungarian Compromise of 1867 established the dual monarchy of Austria-Hungary, which was a military and diplomatic alliance of two sovereign states. The Compromise only partially re-established the former pre-1848 sovereignty and status of the Kingdom of Hungary, being separate from, and no longer subject to, the Austrian Empire. The compromise put an end to the 18-year-long military dictatorship and absolutist rule over Hungary which Emperor Franz Joseph had instituted after the Hungarian Revolution of 1848. The territorial integrity of the Kingdom of Hungary was restored. The agreement also restored the old historic constitution of the Kingdom of Hungary.

Nagykanizsa, known colloquially as Kanizsa, is a medium-sized city in Zala County in southwestern Hungary. It is a city with county rights.

The Ganz Machinery Works Holding is a Hungarian holding company. Its products are related to rail transport, power generation, and water supply, among other industries.

Tungsram was a manufacturing company located in Hungary and known for their light bulbs and electronics. Established in Újpest in 1896, it initially produced telephones, wires and switchboards. The name "Tungsram" is a portmanteau of tungsten and wolfram, the two common names of the metal used for making light bulb filaments. Before becoming nationalized by the Communist government in 1945, the company was the world's third largest manufacturer of light bulbs and radiotubes, after the American General Electric and RCA companies.

The Hungarian State Railways is the Hungarian national railway company and the MÁV Pályaműködtetési Zrt. is the railway infrastructure manager, with subsidiaries "MÁV Személyszállítási Zrt.", and "Utasellátó".

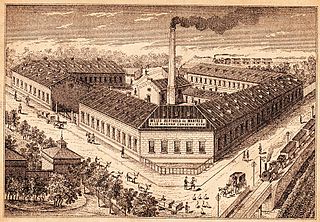

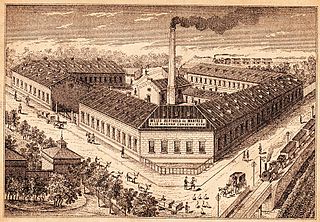

Ábrahám Ganz was a Swiss-born iron manufacturer, machine and technical engineer, entrepreneur, father of Ganz Works. He was the founder and the manager of the company that he made the flagship of the Hungarian economy in the 19th century. Despite his early death in 1867 the company remained one of the strongest manufacturing enterprise in Austria-Hungary. Many famous engineers worked at Ganz Works inter alia Károly Zipernowsky, Ottó Bláthy, Miksa Déri, András Mechwart, Kálmán Kandó, Donát Bánki, János Csonka and Theodore von Kármán and several world-famous inventions were done there, like the first railway electric traction, or the invention of the roller mill, the carburetor, the transformer and the Bánki-Csonka engine.

Orion Electronics Ltd is a consumer electronics company headquartered in Budapest, Hungary. Orion supplies a wide range of brown and white goods including televisions, DVD players/recorders/with HDD, home theatre systems, Navigation Systems, Portable DVD Players, active speaker systems, computer monitors, MP3/MP4 players, washing machines, dishwashers, cooking ranges, microwave ovens and the full range of small domestic appliances. The company is owned and managed by the Thakral Corporation of Singapore.

MÁVAG was the largest Hungarian rail vehicle producer. MÁVAG company was the second largest industrial enterprise after the Manfréd Weiss Steel and Metal Works in the Hungarian half of the Austro-Hungarian Monarchy. MÁVAG was the property of the Kingdom of Hungary. After World War II MÁVAG was nationalized, and "Királyi" ("Royal") was removed from its name.

Economy of the Habsburg monarchy refers to economic development and financial policies of the Habsburg monarchy, until the creation of the Austrian Empire in 1804. Central state institution, that oversaw economic and financial affairs in Habsburg lands, was the Court Chamber, also known as the Aulic Chamber, formed in 1527 by Ferdinand I, and centered in Vienna.

MÁG stands for "Magyar Általános Gépgyár Rt". It was the most prevalent Hungarian vehicle manufacturer before World War II, and was based in Budapest. Its roots date back to 1901, when Podvinecz & Heisler, started assembling Austrian Leesdorfer cars - themselves being French Amédée Bollée cars built under license.

At the outbreak of World War I in August 1914, Hungary was part of the Dual Monarchy of Austria-Hungary. Although there are no significant battles specifically connected to Hungarian regiments, the troops suffered high losses throughout the war as the Empire suffered defeat after defeat. The result was the breakup of the Empire and eventually, Hungary suffered severe territorial losses by the closing Trianon Peace Treaty.

Pester Lloyd is a German-language online daily newspaper from Budapest, Hungary with a focus "on Hungary and Eastern Europe".

Science and technology is one of Hungary's most developed sectors. The country spent 1.4% of its gross domestic product (GDP) on civil research and development in 2015, which is the 25th-highest ratio in the world. Hungary ranks 32nd among the most innovative countries in the Bloomberg Innovation Index, standing before Hong Kong, Iceland or Malta. Hungary was ranked 36th in the Global Innovation Index in 2024.

The Weiss Manfréd Acél- és Fémművek, or colloquially Csepel Művek was one of the largest machine factories in Hungary, located on Csepel island in the southern part of Budapest, founded in 1892. It was the second largest industrial enterprise in the Austro-Hungarian Monarchy, and the biggest industrial enterprise in the Hungarian half of the Empire. It played an integral role in the heavy industry and military production of the Austro-Hungarian Monarchy. Founded by Baron Manfréd Weiss of Csepel, an industrialist of Jewish origin, by the time of World War I the company was one of largest defense contractors in Austria-Hungary, producing all types of equipment, from airplanes and munitions to automotive engines, bicycles Csepel bicycle and cars. Badly damaged by Allied air raids and eventually pillaged during World War II, the company continued in existence until 1950, when it was nationalised and renamed to Rákosi Mátyás Vas- és Fémművek.

The dissolution of Austria-Hungary was a major political event that occurred as a result of the growth of internal social contradictions and the separation of different parts of Austria-Hungary. The more immediate reasons for the collapse of the state were World War I, the 1918 crop failure, general starvation and the economic crisis. The Austro-Hungarian Empire had additionally been weakened over time by a widening gap between Hungarian and Austrian interests. Furthermore, a history of chronic overcommitment rooted in the 1815 Congress of Vienna in which Metternich pledged Austria to fulfill a role that necessitated unwavering Austrian strength and resulted in overextension. Upon this weakened foundation, additional stressors during World War I catalyzed the collapse of the empire. The 1917 October Revolution and the Wilsonian peace pronouncements from January 1918 onward encouraged socialism on the one hand, and nationalism on the other, or alternatively a combination of both tendencies, among all peoples of the Habsburg monarchy.

András Mechwart de Belecska was a German-born Hungarian-German mechanical engineer, chief executive of the Ganz Works, and a pioneer in the Hungarian mechanical and electrical engineering. As an inventor and as a businessman he contributed to the development of the Hungarian transport manufacturing industry, and made the Ganz Works a flagship of the Hungarian economy of the 19th century.

During its existence, Austria-Hungary did not have a common flag – a "national flag" could not exist since the Dual Monarchy consisted of two sovereign states. However, the black-gold flag of the ruling Habsburg Dynasty was sometimes used as a de facto national flag and a common civil ensign was introduced in 1869 for civilian vessels. Until 1918, the k.u.k. War Fleet continued to carry the Austrian ensign it had used since 1786 and the regiments of the k.u.k. Army carried the double-eagle banners they had used before 1867, as they had a long history in many cases. New ensigns created in 1915 were not implemented due to the ongoing war. At state functions, the Austrian black-gold and the Hungarian red-white-green tricolor were used.

The Austro-Hungarian Bank was the central bank of the Habsburg Monarchy in the 19th and early 20th centuries.