In an internal combustion engine, a turbocharger is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement.

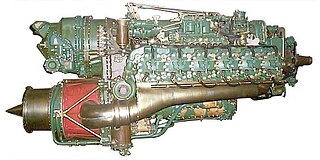

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

Jeannette is a city in Westmoreland County, Pennsylvania, United States. Jeannette was founded in 1888. The city got its name from one of the original city fathers, who wished to honor his wife, Jeannette McLaughlin, by giving the new town her first name: Jeannette. The city celebrated its 125th anniversary in July 2013. The population was 9,654 according to the 2010 census.

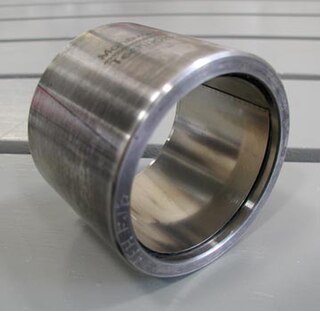

Centrifugal compressors, sometimes called impeller compressors or radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.

Garrett Motion Inc., formerly Honeywell Transportation Systems and Honeywell Turbo Technologies, is an American company primarily involved in engineering, development and manufacturing of turbochargers and related forced induction systems for ground vehicles from small passenger cars to large trucks and industrial equipment and construction machinery. It originated as part of Garrett AiResearch's Industrial Division in Phoenix, Arizona, in 1954, after which they entered a contract to provide 5,000 turbochargers for the Caterpillar mining vehicle. It manufactured turbochargers for railroads and commercial trucks. The business produced approximately $3.6 billion in revenue in 2021. Garrett Motion is also involved in motorsports providing turbochargers and forced induction systems, solutions and related equipment to racing teams and various forms of automobile racing and professional competitions. In 2004, the business became part of American industrial conglomerate Honeywell International, Inc., as their Transportation Systems division. In 2018, it was spun off to become an independent company under the Garrett Motion name with corporate headquarters in Rolle, Switzerland.

A wastegate is a valve that controls the flow of exhaust gases to the turbine wheel in a turbocharged engine system.

The anti-lag system (ALS) is a method of reducing turbo lag or effective compression used on turbocharged engines to minimize turbo lag on racing or performance cars. It works by delaying the ignition timing and adding extra fuel to balance an inherent loss in combustion efficiency with increased pressure at the charging side of the turbo. This is achieved as an excess amount of fuel/air mixture escapes through the exhaust valves and combusts in the hot exhaust manifold spooling the turbocharger creating higher usable pressure.

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid.

Variable-geometry turbochargers (VGTs), occasionally known as variable-nozzle turbines (VNTs), are a type of turbochargers, usually designed to allow the effective aspect ratio of the turbocharger to be altered as conditions change. This is done with the use of adjustable vanes located inside the turbine housing between the inlet and turbine, these vanes affect flow of gases towards the turbine. The benefit of the VGT is that the optimum aspect ratio at low engine speeds is very different from that at high engine speeds.

A compressor map is a chart which shows the performance of a turbomachinery compressor. This type of compressor is used in gas turbine engines, for supercharging reciprocating engines and for industrial processes, where it is known as a dynamic compressor. A map is created from compressor rig test results or predicted by a special computer program. Alternatively the map of a similar compressor can be suitably scaled. This article is an overview of compressor maps and their different applications and also has detailed explanations of maps for a fan and intermediate and high-pressure compressors from a three-shaft aero-engine as specific examples.

A twincharger refers to a compound forced induction system used on some internal combustion engines. It is a combination of an exhaust-driven turbocharger and a mechanically driven supercharger, each mitigating the weaknesses of the other.

Twin-turbo refers to an engine in which two turbochargers work in tandem to compress the intake fuel/air mixture. The most common layout features two identical or mirrored turbochargers in parallel, each processing half of a V engine's produced exhaust through independent piping. The two turbochargers can either be matching or different sizes.

Mohawk Innovative Technology, Inc. is an American product and research and development technology company that develops oil-free foil bearings, magnetic bearings and non-contacting foil seals for high-speed rotating machinery, such as gas turbine engines, turbochargers, compressors, cryogenic pumps, variable high-speed motors/generators and machines.

The EMD 567 is a line of large medium-speed diesel engines built by General Motors' Electro-Motive Division. This engine, which succeeded Winton's 201A, was used in EMD's locomotives from 1938 until its replacement in 1966 by the EMD 645. It has a bore of 8+1⁄2 in (216 mm), a stroke of 10 in (254 mm) and a displacement of 567 cu in (9.29 L) per cylinder. Like the Winton 201A, the EMD 645 and the EMD 710, the EMD 567 is a two-stroke engine.

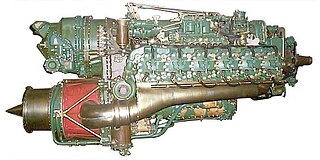

A turbo-compound engine is a reciprocating engine that employs a turbine to recover energy from the exhaust gases. Instead of using that energy to drive a turbocharger as found in many high-power aircraft engines, the energy is instead sent to the output shaft to increase the total power delivered by the engine. The turbine is usually mechanically connected to the crankshaft, as on the Wright R-3350 Duplex-Cyclone, but electric and hydraulic power recovery systems have been investigated as well.

Compression Systems, one of five organizational groups within Cameron International Corporation, is a provider of reciprocating and centrifugal compression equipment and aftermarket parts and services. Reciprocating compression equipment is used throughout the energy industry by gas transmission companies, compression leasing companies, oil and gas producers and independent power producers. Integrally geared centrifugal compressors are used by customers around the world in a variety of industries such as air separation, auto making, glass blowing, PET, petrochemical and chemical. Reciprocating compression was sold to GE Oil and Gas in June 2014.

Ebara Corporation is a publicly traded manufacturing company based in Tokyo, Japan which makes environmental and industrial machinery such as pumps and turbines. It is the owner of the Elliott Company in the United States and Sumoto S.r.l. in Italy.

An electrically-assisted turbocharger (EAT) is an arrangement where an electric motor assists the gas-driven turbocharger in providing forced induction, particular at times when exhaust gas flow is insufficient to produce the desired boost. Some systems integrate the motor inside a turbocharger, while others use a separate electric supercharger.

MAN Energy Solutions SE is a German multinational company based in Augsburg that produces large-bore gas and diesel engines and also turbomachinery for marine, rail and stationary applications, as locomotive and marine propulsion systems, power plant applications, and turbochargers. The company was formed in 2010 from the merger of MAN Diesel and MAN Turbo. MAN Energy Solutions is a subsidiary of the German carmaker Volkswagen Group.

Cameron International Corporation (formerly Cooper Cameron Corporation (CCC) and Cooper Oil Tool, Cameron Iron Works) though now operating under Schlumberger, is a global provider of pressure control, production, processing, and flow control systems as well as project management and aftermarket services for the oil and gas and process industries. Cameron was acquired by Schlumberger (SLB) in 2016, and now operates as 'Cameron, a Schlumberger Company.' At the start of the SLB acquisition in 2015, Cameron employed approximately 23,000 people and delivered $9.8 billion in revenue.