A cereal is a grass cultivated for its edible grain. Cereals are the world's largest crops, and are therefore staple foods. They include rice, wheat, rye, oats, barley, millet, and maize. Edible grains from other plant families, such as buckwheat and quinoa, are pseudocereals. Most cereals are annuals, producing one crop from each planting, though rice is sometimes grown as a perennial. Winter varieties are hardy enough to be planted in the autumn, becoming dormant in the winter, and harvested in spring or early summer; spring varieties are planted in spring and harvested in late summer. The term cereal is derived from the name of the Roman goddess of grain crops and fertility, Ceres.

Malt is any cereal grain that has been made to germinate by soaking in water and then stopped from germinating further by drying with hot air, a process known as "malting". Malted grain is used to make beer, whisky, malted milk, malt vinegar, confections such as Maltesers and Whoppers, flavored drinks such as Horlicks, Ovaltine, and Milo, and some baked goods, such as malt loaf, bagels, and Rich Tea biscuits. Malted grain that has been ground into a coarse meal is known as "sweet meal".

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants for energy storage. Worldwide, it is the most common carbohydrate in human diets, and is contained in large amounts in staple foods such as wheat, potatoes, maize (corn), rice, and cassava (manioc).

Flour is a powder made by grinding raw grains, roots, beans, nuts, or seeds. Flours are used to make many different foods. Cereal flour, particularly wheat flour, is the main ingredient of bread, which is a staple food for many cultures. Corn flour has been important in Mesoamerican cuisine since ancient times and remains a staple in the Americas. Rye flour is a constituent of bread in both Central Europe and Northern Europe.

A mochi is a Japanese rice cake made of mochigome (もち米), a short-grain japonica glutinous rice, and sometimes other ingredients such as water, sugar, and cornstarch. The steamed rice is pounded into paste and molded into the desired shape. In Japan, it is traditionally made in a ceremony called mochitsuki. While eaten year-round, mochi is a traditional food for the Japanese New Year, and is commonly sold and eaten during that time.

Amylose is a polysaccharide made of α-D-glucose units, bonded to each other through α(1→4) glycosidic bonds. It is one of the two components of starch, making up approximately 20–30%. Because of its tightly packed helical structure, amylose is more resistant to digestion than other starch molecules and is therefore an important form of resistant starch.

Wheat flour is a powder made from the grinding of common wheat used for human consumption. Wheat varieties are called "soft" or "weak" if gluten content is low, and are called "hard" or "strong" if they have high gluten content. Hard flour, or bread flour, is high in gluten, with 12% to 14% gluten content, and its dough has elastic toughness that holds its shape well once baked. Soft flour is comparatively low in gluten and thus results in a loaf with a finer, crumbly texture. Soft flour is usually divided into cake flour, which is the lowest in gluten, and pastry flour, which has slightly more gluten than cake flour.

Parboiled rice, also called converted rice, easy-cook rice, sella rice, and miniket is rice that has been partially boiled in the husk. The three basic steps of parboiling are soaking, steaming and drying. These steps make the rice easier to process by hand, while also boosting its nutritional profile, changing its texture, and making it more resistant to weevils. The treatment is practiced in many other parts of the world.

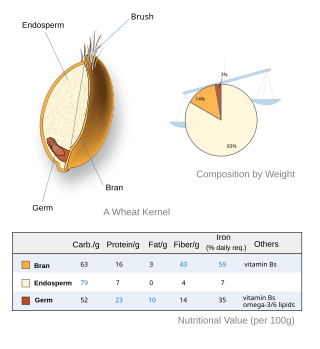

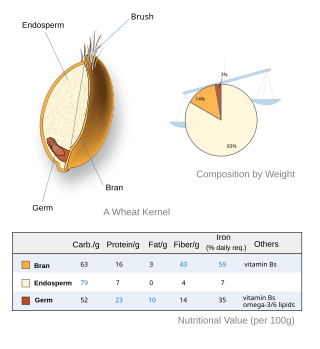

A whole grain is a grain of any cereal and pseudocereal that contains the endosperm, germ, and bran, in contrast to refined grains, which retain only the endosperm.

Digitaria exilis, referred to as findi or fundi in areas of Africa, such as The Gambia, with English common names white fonio, fonio millet, and hungry rice or acha rice, is a grass species. It is the most important of a diverse group of wild and domesticated Digitaria species known as fonio that are harvested in the savannas of West Africa. The grains are very small. It has potential to improve nutrition, boost food security, foster rural development and support sustainable use of the land. Despite its valuable characteristics and widespread cultivation, fonio has generally received limited research and development attention, which is also why the species is sometimes referred to as an underutilized crop.

Corn kernels are the fruits of corn. Maize is a grain, and the kernels are used in cooking as a vegetable or a source of starch. The kernel comprise endosperm, germ, pericarp, and tip cap.

Waxy corn or glutinous corn is a type of field corn characterized by its sticky texture when cooked as a result of larger amounts of amylopectin. The corn was first described from a specimen from China in 1909. As this plant showed many peculiar traits, the American breeders long used it as a genetic marker to tag the existence of hidden genes in other maize breeding programs. In 1922 a researcher found that the endosperm of waxy maize contained only amylopectin and no amylose starch molecule in opposition to normal dent corn varieties that contain both. Until World War II, the main source of starch in the United States was tapioca, but when Japan severed the supply lines of the U.S., they forced processors to turn to waxy maize. Amylopectin or waxy starch is now used mainly in food products, but also in the textile, adhesive, corrugating and paper industry.

Grains may be lost in the pre-harvest, harvest, and post-harvest stages. Pre-harvest losses occur before the process of harvesting begins, and may be due to insects, weeds, and rusts. Harvest losses occur between the beginning and completion of harvesting, and are primarily caused by losses due to shattering. Post-harvest losses occur between harvest and the moment of human consumption. They include on-farm losses, such as when grain is threshed, winnowed, and dried. Other on-farm losses include inadequate harvesting time, climatic conditions, practices applied at harvest and handling, and challenges in marketing produce. Significant losses are caused by inadequate storage conditions as well as decisions made at earlier stages of the supply chain, including transportation, storage, and processing, which predispose products to a shorter shelf life.

Malting is the process of steeping, germinating and drying grain to convert it into malt. Germination and sprouting involve a number of enzymes to produce the changes from seed to seedling and the malt producer stops this stage of the process when the required enzymes are optimal. Among other things, the enzymes convert starch to sugars such as maltose, maltotriose and maltodextrines.

Grain damage is any degradation in the quality of grain. In the current grain trade, this damage can affect price, feed quality, food product quality, and susceptibility to pest contamination.

Grain drying is the process of drying grain to prevent spoilage during storage. Artificial grain drying uses fuel or electricity powered processes supplementary to natural ones, including swathing/windrowing for air and sun drying, or stooking before threshing.

Puffcorn or corn puffs are puffed or extruded corn snacks made with corn meal, which can be baked or fried.

Corn wet-milling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and fiber. It uses water and a series of steps to separate the parts to be used for various products.

Dry milling of grain is mainly utilized to manufacture feedstock into consumer and industrial based products. This process is widely associated with the development of new bio-based associated by-products. The milling process separates the grain into four distinct physical components: the germ, flour, fine grits, and coarse grits. The separated materials are then reduced into food products utilized for human and animal consumption.

Rice is commonly consumed as food around the world. It occurs in long-, medium-, and short-grained types. It is the staple food of over half the world's population.