| |

| |

| Names | |

|---|---|

| Preferred IUPAC name 1,6-Diisocyanatohexane | |

| Other names HDI 1,6-hexane diisocyanate | |

| Identifiers | |

3D model (JSmol) | |

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.011.350 |

PubChem CID | |

| UNII |

|

CompTox Dashboard (EPA) | |

| |

| |

| Properties | |

| C8H12N2O2 | |

| Molar mass | 168.2 g/mol |

| Appearance | Colourless liquid |

| Odor | sharp, pungent [1] |

| Density | 1.047 g/cm3, liquid |

| Melting point | −67 °C (−89 °F; 206 K) |

| Boiling point | 255 °C (491 °F; 528 K) |

| Vapor pressure | 0.05 mmHg (25 °C) [1] |

| Viscosity | 3 cP at 25 °C |

| Hazards | |

| Flash point | 130–140 °C (266–284 °F; 403–413 K) (Cleveland open cup) |

| NIOSH (US health exposure limits): | |

PEL (Permissible) | none [1] |

REL (Recommended) | TWA 0.005 ppm (0.035 mg/m3) C 0.020 ppm (0.140 mg/m3) [10-minute] [1] |

IDLH (Immediate danger) | N.D. [1] |

| Related compounds | |

Related isocyanates | Isophorone diisocyanate |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

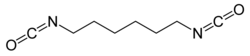

Hexamethylene diisocyanate (HDI) is the organic compound with the formula (CH2)6(NCO)2. It is classified as an diisocyanate. It is a colorless liquid. [2] It has sometimes been called HMDI [3] but this not usually done to avoid confusion with Hydrogenated MDI.