Newport News Shipbuilding (NNS), a division of Huntington Ingalls Industries, is the sole designer, builder, and refueler of aircraft carriers and one of two providers of submarines for the United States Navy. Founded as the Chesapeake Dry Dock and Construction Co. in 1886, Newport News Shipbuilding has built more than 800 ships, including both naval and commercial ships. Located in the city of Newport News, Virginia, its facilities span more than 550 acres (2.2 km2).

The Westinghouse Electric Corporation was an American manufacturing company founded in 1886 by George Westinghouse and headquartered in Pittsburgh, Pennsylvania. It was originally named "Westinghouse Electric & Manufacturing Company" and was renamed "Westinghouse Electric Corporation" in 1945. Through the early and mid-20th century, Westinghouse Electric was a powerhouse in heavy industry, electrical production and distribution, consumer electronics, home appliances and a wide variety of other products. They were a major supplier of generators and steam turbines for most of their history, and was also a major player in the field of nuclear power, starting with the Westinghouse Atom Smasher in 1937.

Six Companies, Inc. was a joint venture of construction companies that was formed to build the Hoover Dam on the Colorado River in Nevada and Arizona.

Avondale Shipyard was an independent shipbuilding company, acquired by Litton Industries, in turn acquired by Northrop Grumman Corporation. In 2011, along with the former Ingalls Shipbuilding, the yard was part of Huntington Ingalls Industries. It closed in October 2014. The yard was located on the west bank of the Mississippi River in an area called Bridge City, about 20 miles (32 km) upriver from New Orleans near Westwego, Louisiana. It was the site of the modernization of the battleship USS Iowa in the early 1980s and also constructed some of the lighter aboard ships (LASH). At one time, it was the largest employer in Louisiana, with about 26,000 employees.

Union Iron Works, located in San Francisco, California, on the southeast waterfront, was a central business within the large industrial zone of Potrero Point, for four decades at the end of the nineteenth and beginning of the twentieth centuries.

Northrop Grumman Electronic Systems (NGES) was a business segment of Northrop Grumman from 1996 to 2015, until a reorganization on January 1 2016 merged other Northrop Grumman businesses into NGES to form a new segment called Mission Systems. NGES had originally been created by Northrop Grumman's acquisition of Westinghouse Electronic Systems Group in 1996. The Electronic Systems sector was a designer, developer, and manufacturer of a wide variety of advanced defense electronics and systems. The division had 120 locations worldwide, including 72 international offices, and approximately 24,000 employees; accounting for 20% of company sales in 2005.

The Consolidated Steel Corporation was an American steel and shipbuilding business. Formed on 18 December 1928, the company built ships during World War II in two main locations: Wilmington, California, and Orange, Texas. It was created by the merger of Llewellyn Iron Works, Baker Iron Works and Union Iron Works, all of Los Angeles. The company entered the shipbuilding business in 1939. In 1948, now a pioneer producer of large-diameter pipelines, Consolidated Steel was renamed Consolidated Western Steel and acquired by U.S. Steel and operated as a wholly-owned subsidiary.

Neafie, Levy & Co., commonly known as Neafie & Levy, was a Philadelphia, Pennsylvania shipbuilding and engineering firm that existed from the middle of the 19th to the beginning of the 20th century. Described as America's "first specialist marine engineers", Neafie & Levy was probably the first company in the United States to combine the building of iron ships with the manufacture of steam engines to power them. The company was also the largest supplier of screw propellers to other North American shipbuilding firms in its early years, and at its peak in the early 1870s was Philadelphia's busiest and most heavily capitalized shipbuilder.

The Morgan Iron Works was a 19th-century manufacturing plant for marine steam engines located in New York City, United States. Founded as T. F. Secor & Co. in 1838, the plant was later taken over and renamed by one of its original investors, Charles Morgan.

Willamette Iron Works was a general foundry and machine business established in 1865 in Portland, Oregon, originally specializing in the manufacture of steamboat boilers and engines. In 1904, the company changed its name to Willamette Iron and Steel Works, under which name it operated continually until its close in 1990.

Charles Edward Moore was an American industrialist who is best known for his contribution to the maritime shipbuilding industry during World War II.

Hitachi Zosen Corporation is a major Japanese industrial and engineering corporation. It produces waste treatment plants, industrial plants, precision machinery, industrial machinery, steel mill process equipment, steel structures, construction machinery, tunnel boring machines, and power plants. Despite its name, Hitachi Zosen, of which the last word literally means shipbuilding, no longer builds ships, having spun off the business to Universal Shipbuilding Corporation in 2002, nor is it a keiretsu company of Hitachi any longer.

The Etna Iron Works was a 19th-century New York ironworks and steam engineering plant, best known for its manufacture of marine steam engines during and after the American Civil War.

Reaney, Son & Archbold was a 19th-century American iron shipbuilding company located on the Delaware River at Chester, Pennsylvania. The company was established in 1859 by Thomas Reaney but it was undercapitalized from the outset, and like many other American shipbuilding companies, fell victim to the shipbuilding slump that followed the American Civil War.

The Delaware River Iron Ship Building and Engine Works was a major late-19th-century American shipyard located on the Delaware River in Chester, Pennsylvania. It was founded by the industrialist John Roach and is often referred to by its parent company name of John Roach & Sons, or just known as the Roach shipyard. For the first fifteen years of its existence, the shipyard was by far the largest and most productive in the United States, building more tonnage of ships than its next two major competitors combined, in addition to being the U.S. Navy's largest contractor. The yard specialized in the production of large passenger freighters, but built every kind of vessel from warships to cargo ships, oil tankers, ferries, barges, tugs and yachts.

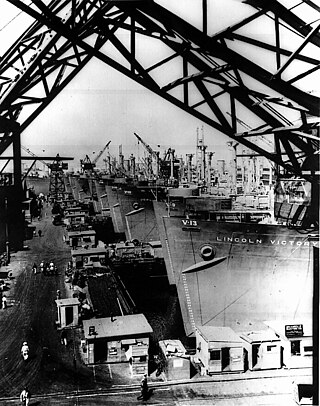

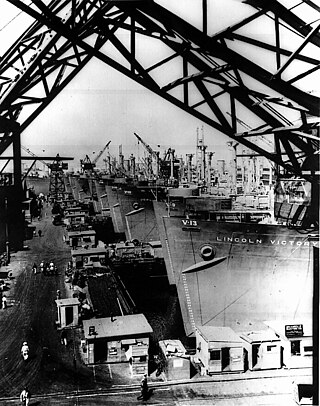

The Ocean ships were a class of sixty cargo ships built in the United States by Todd Shipyards Corporation during the Second World War for the British Ministry of War Transport under contracts let by the British Purchasing Commission. Eighteen were lost to enemy action and eight to accidents; survivors were sold postwar into merchant service.

Nordberg Manufacturing Company was a manufacturer of steam engines, large diesel engines, pumps, hoists and compressors for the mining and quarry industries located in Milwaukee, Wisconsin.

The SSPanama Victory was a Victory ship built during World War II. She was launched by the California Shipbuilding Company on April 3, 1944 and completed on May 30, 1944. She was built in 115 days under the Emergency Shipbuilding program. The ship’s United States Maritime Commission designation was VC2-S-AP3, hull number 9 (V-9). SS Panama Victory served in the Pacific Ocean during World War II. SS Panama Victory was ninth of the new 10,500-ton class ship to be known as Victory ships. Victory ships were designed to replace the earlier Liberty Ships. Liberty ships were designed to be used just for WW2. Victory ships were designed to last longer and serve the US Navy after the war. The Victory ship differed from a Liberty ship in that they were: faster, longer and wider, taller, had a thinner stack set farther toward the superstructure and had a long raised forecastle. Engine was made by Joshua Hendy Iron Works Inc. of Sunnyvale, California.

California during World War II was a major contributor to the World War II effort. California's long Pacific Ocean coastline provided the support needed for the Pacific War. California also supported the war in Europe. After the Japanese attack on Pearl Harbor on December 7, 1941, most of California's manufacturing was shifted to the war effort. California became a major ship builder and aircraft manufacturer. Existing military installations were enlarged and many new ones were built. California trained many of the troops before their oversea deployment. Over 800,000 Californians served in the United States Armed Forces. California agriculture, ranches and farms were used to feed the troops around the world. California's long coastline also put the state in fear, as an attack on California seemed likely. California was used for the temporary and permanent internment camps for Japanese Americans. The population grew significantly, largely due to servicemen who were stationed at the new military bases/training facilities and the mass influx of workers from around the U.S. in the growing defense industries. With all the new economy activity, California was lifted out of the Great Depression. Over 500,000 people moved to California from other states to work in the growing economy. California expanded its oil and mineral production to keep up with the war demand.

Pacific Tankers, Inc. of San Francisco, California, was founded in 1943 as a division of Joshua Hendy Corporation to operate fleet oilers for the United States Navy to support World War II efforts. Pacific Tankers, Inc. operated Mission Buenaventura-class oiler, a T2 tanker (T2-SE-A2). Each Pacific Tankers, Inc. tanker had a merchant crew of about 9 officers and 39 men. Pacific Tankers Inc. was a major tanker operator for the war with a fleet of over 60 tankers. Pacific Tankers, Inc. continued operations after the war.