A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of references to the preceding generation engine technology of the turbojet and the additional fan stage. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Aircraft using power components are referred to as powered flight. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors.

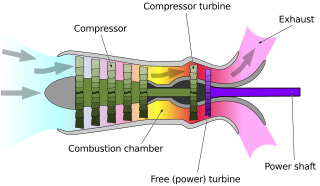

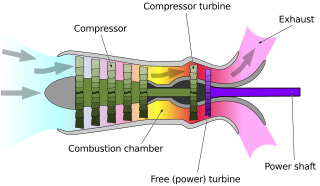

A turboshaft engine is a form of gas turbine that is optimized to produce shaft horsepower rather than jet thrust. In concept, turboshaft engines are very similar to turbojets, with additional turbine expansion to extract heat energy from the exhaust and convert it into output shaft power. They are even more similar to turboprops, with only minor differences, and a single engine is often sold in both forms.

UEC NPO Saturn, PJSC is a Russian aircraft engine manufacturer, formed from the mergers of Rybinsk Motors and Lyul'ka-Saturn in 2001. Saturn's engines power many former Eastern Bloc aircraft, such as the Tupolev Tu-154. Saturn holds a 50% stake in the PowerJet joint venture with Safran Aircraft Engines. The company, founded by Pavel Soloviev, has its headquarters in the town of Rybinsk.

The Mikoyan-Gurevich MiG-110 was a proposed Russian passenger/cargo aircraft that began development in 1995 but was not built. It would have been a high-mounted cantilever monoplane with a pod-and-boom configuration with a beavertail rear fuselage, to be powered by two Klimov TV7-117 turboprop engines.

The Klimov VK-1 was the first Soviet jet engine to see significant production. It was developed by Vladimir Yakovlevich Klimov and first produced by the GAZ 116 works. Derived from the Rolls-Royce Nene, the engine was also built under licence in China as the Wopen WP-5.

The Klimov RD-33 is a turbofan jet engine for a lightweight fighter jet and which is the primary engine for the Mikoyan MiG-29 and CAC/PAC JF-17 Thunder. It was developed in OKB-117 led by S. P. Izotov from 1968 with production starting in 1981. Previous generations of Russian supersonic fighters such as the MiG-21 and MiG-23 used turbojets, but western fighters such as the F-111 and F-4K introduced the use of afterburning turbofans in the 1960s which were more efficient.

The Ilyushin Il-112/Il-212 is a high-wing light military transport aircraft being developed by Ilyushin Aviation Complex for air landing and airdrop of military air cargoes, equipment and personnel. The aircraft is manufactured by Voronezh Aircraft Production Association in Voronezh. In October 2023, according to a source inside the Russian industrial-military complex, it was reported that the Il-112 project will be redesigned and renamed into the Ilyushin Il-212, the main difference being that now the aircraft will be equipped with turbofan instead of turboprop.

The Omsk Engine Design Bureau is an aero engine design bureau. It was originally situated in Moscow in the Soviet Union, but was evacuated in 1941. Operations were moved to a "site of farm machinery". The Bureau returned to Moscow and became independent on 5 July 1947 and was renamed "OKB-20". The bureau absorbed OKB-29 in 1963 and in 1966 was renamed Mashinostoitel'noe KB (MKB). Since 1994, it has been known as Omskoe mashinstroitel'noe KB.

UEC-Aviadvigatel JSC is a Russian developer and builder of aircraft engines, most notably jet engines for commercial aircraft. Based at the Perm Engine Plant, its products power the Ilyushin Il-76MF, Ilyushin Il-96, Tupolev Tu-204, and Tupolev Tu-214. It also designs and builds high-efficiency gas turbine units for electric power stations and for gas pumping plants. The company has its background in the Experimental Design Bureau-19 plant, set up to manufacture aircraft engines.

The Klimov TV3-117 is a Soviet gas turbine aero engine. It is used in most medium lift, utility, and attack helicopters designed by the Mil and Kamov design bureaus. The TV3-117 turboshaft engine was developed in 1974. Later the Klimov TV3-117 was installed on 95% of all helicopters designed by Mil and Kamov Engineering Centre. The engine has been produced in many variants.

The Klimov TV7-117 is a Russian turboprop engine certified in 1997 to power the Ilyushin Il-114 regional commuter aircraft. The new engine features enhanced reliability, fuel economy and greater service life compared to its predecessors produced in the former Soviet Union. The engine has a modular design. The nine modules can be replaced in the field, which dramatically reduces costs and accelerates repair and maintenance. The engine has an electronic-hydromechanical control system.

The Klimov VK-800 is a turboshaft engine of the fifth generation. It is designed to equip the Mi-54, Ansat and Ka-226 "Sergei" type helicopters. The VK-800V derivative was developed for the power units of helicopters of small and large load-carrying capacity, both in twin- and single-engine configuration. The engine parameters meet the requirements of the tested model of a centrifugal compressor and the single-stage un-cooled turbines. All this simplifies the engine design and reduces expenses for its manufacture and operation. Moreover, the enhanced characteristics of the main units of the engine provide its high efficiency.

The Klimov VK-2500 is a Russian turboshaft aero engine, a high power derivative of the TV3-117VMA engine, also for hot and high.

The Klimov TV2-117 is a Soviet gas-turbine turboshaft engine intended for helicopter use. Designed in the early 1960s by the Isotov Design Bureau the engine became the first purpose built gas turbine engine for helicopter use by the Soviet Union with previous helicopter turbines being adapted aeroplane powerplants. It was later produced by Klimov, production ending in 1997.

The Klimov GTD-350 is a Soviet gas-turbine turboshaft engine intended for helicopter use. Designed in the early 1960s by the Isotov Design Bureau the engine was later produced by Klimov and PZL, production ending in the late 1990s.

The Ivchenko AI-24 turboprop aircraft engine was designed and developed in the late-1950s by the Ivchenko design bureau and manufactured thereafter by Motor Sich. It was designed to power Antonov's successful An-24, An-26 and An-30 aircraft series.

The Klimov VK-3 was the first Soviet afterburning bypass turbojet engine. Designed by S V Lyunevich at Klimov, at OKB-117 in 1949, this engine first ran in 1952, and was qualified at 5,730 kg (12,632 lb) thrust (dry) and 8,440 kg (18,607 lb) thrust in 1954. The VK-3 was developed for the Mikoyan-Gurevich I-3 (I-380) and I-3U/I-5 (I-410) fighters. First flown in the I-3U in July 1956, the engine's performances was good but its reliability was poor. Even after modifications in December 1956 when newly designed compressor blades were installed, developmental problems continued, the program was ultimately canceled in January 1958. The engine was superseded by the Lyulka AL-7F, a less modern but more efficient engine.

Salyut Machine-Building Production Association is a company based in Moscow, Russia. NPC Salyut have three plants and office with further plants outside Moscow city. It is a subsidiary of United Engine Corporation.

Ural Works of Civil Aviation is an aircraft manufacturing and aircraft repair enterprise, one of the major manufacturers in the aircraft manufacturing industry in Russia. It specializes in the development, production, testing, repair and maintenance of aircraft equipment, components and assemblies. The company includes a production center for engine maintenance and repair, aircraft manufacturing facilities, an engineering center, and a number of subsidiaries, affiliates, and separate companies.