Dudd (Dud) Dudley (1600–1684) was an English metallurgist, who fought on the Royalist side in the English Civil War as a soldier, military engineer, and supplier of munitions. He was one of the first Englishmen to smelt iron ore using coke.

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

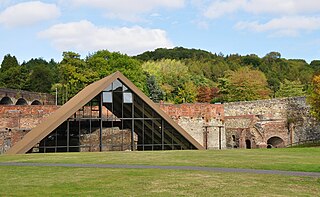

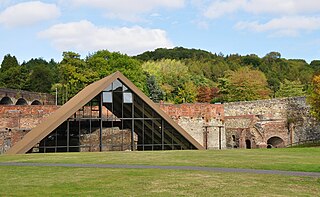

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term reverberation is used here in a generic sense of rebounding or reflecting, not in the acoustic sense of echoing.

Boliden AB is a Swedish mining and smelting company focusing on production of copper, zinc, lead, gold and silver. Following a series of acquisitions during the 1980s and 1990s the company acquired mining and smelting assets of the Finnish mining and smelting company Outokumpu in 2003. Outokumpu acquired the subsidiary Boliden Contech and Boliden's copper and zinc divisions. As a consequence of the deal, Outokumpu ended up controlling 49 percent of the Boliden shares.

Abraham Darby, in his later life called Abraham Darby the Elder, now sometimes known for convenience as Abraham Darby I, was the first and best known of several men of that name. Born into an English Quaker family that played an important role in the Industrial Revolution, Darby developed a method of producing pig iron in a blast furnace fuelled by coke rather than charcoal. This was a major step forward in the production of iron as a raw material for the Industrial Revolution.

Sir Clement Clerke, 1st Baronet was an important English entrepreneur, whose greatest achievement was the application of the reverberatory furnace (cupola) to smelting lead and copper, and to remelting pig iron for foundry purposes.

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has pioneered several significant mining industry innovations, including the Isa Process copper refining technology, the Isasmelt smelting technology, and the IsaMill fine grinding technology, and it also commercialized the Jameson Cell column flotation technology.

Henry Howard, 5th Earl of Suffolk was the youngest son of Theophilus Howard, 2nd Earl of Suffolk, but inherited the title, because none of his brothers left surviving sons.

The Chillagoe smelters is a heritage-listed refinery at Chillagoe-Mungana Caves National Park, Mareeba Mining District, Chillagoe, Shire of Mareeba, Queensland, Australia. It operated in the early 1900s. It is also known as Chillagoe State Smelters. It was added to the Queensland Heritage Register on 21 October 1992.

The Quincy Smelter, also known as the Quincy Smelting Works, is a former copper smelter located on the north side of the Keweenaw Waterway in Ripley, Michigan. It is a contributing property of the Quincy Mining Company Historic District, a National Historic Landmark District. The smelter was built in 1898 by the Quincy Mining Company, operating from 1898 to 1931 and again from 1948 to 1971. The smelter was part of a Superfund site from 1986 to 2013.

The Michigan Smelter was a copper smelter located at Cole's Creek on the Keweenaw Waterway north-west of Houghton, Michigan near the old Atlantic mill. The smelter was created in 1903-4 as a joint effort between the Copper Range Company and Stanton group of mines. An Atlantic dam on the site was reused by the smelter as a water source. In 1905, the smelter broke a world record by casting 292,000 pounds of fine copper in seven hours with a single furnace and only ten men. The smelter operated through World War II and stopped all operations in 1948.

Mount Clara smelter is a heritage-listed former copper smelter at Rossmore Road, in the upper reaches of Fat Hen Creek, Oakview, Gympie Region, Queensland, Australia. It was built in 1873. It was added to the Queensland Heritage Register on 21 October 1992.

Plants for the production of lead are generally referred to as lead smelters. Primary lead production begins with sintering. Concentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates. Smelting uses suitable reducing substances that will combine with those oxidizing elements to free the metal. Reduction is the final, high-temperature step in smelting. It is here that the oxide becomes the elemental metal. A reducing environment pulls the final oxygen atoms from the raw metal.

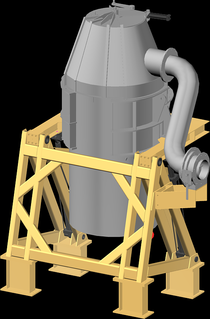

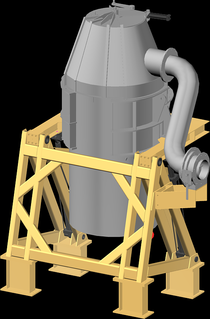

The ISASMELT process is an energy-efficient smelting process that was jointly developed from the 1970s to the 1990s by Mount Isa Mines Limited and the Australian government’s Commonwealth Scientific and Industrial Research Organisation ("CSIRO"). It has relatively low capital and operating costs for a smelting process.

The Bottom-blown Oxygen Converter or BBOC is a smelting furnace developed by the staff at Britannia Refined Metals Limited (“BRM”), a British subsidiary of MIM Holdings Limited. The furnace is currently marketed by Glencore Technology. It is a sealed, flat-bottomed furnace mounted on a tilting frame that is used in the recovery of precious metals. A key feature is the use of a shrouded lance to inject oxygen through the bottom of the furnace, directly into the precious metals contained in the furnace, to oxidize base metals or other impurities as part of their removal as slag.

Sundown Tin and Copper Mine is a heritage-listed mine at Little Sundown Creek, Stanthorpe, Southern Downs Region, Queensland, Australia. It was built from c. 1897 to 1920s. It was added to the Queensland Heritage Register on 28 July 2000.

Glassford Creek Smelter Sites are the heritage-listed remains of a former smelter at Glassford State Forest, off Many Peaks Road, Many Peaks, Gladstone Region, Queensland, Australia. It was built c. 1903. It is also known as Glassford Creek Copper Smelters. It was added to the Queensland Heritage Register on 4 July 2006.

Norton Goldfield is a heritage-listed former mine at Norton Road, near Nagoorin, Boyne Valley, Gladstone Region, Queensland, Australia. It was built from 1870s to 1941. It is also known as Milton Goldfield. It was added to the Queensland Heritage Register on 27 October 2006.

Adolphus William Copper Smelter is a heritage-listed former copper smelter and associated mining camp at Westwood and Oakey Creek in Rockhampton Region, Queensland, Australia. It was built in 1874. It was added to the Queensland Heritage Register on 13 May 2011.