In passive solar building design, windows, walls, and floors are made to collect, store, reflect, and distribute solar energy, in the form of heat in the winter and reject solar heat in the summer. This is called passive solar design because, unlike active solar heating systems, it does not involve the use of mechanical and electrical devices.

Thermal insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials.

In the study of heat transfer, radiative cooling is the process by which a body loses heat by thermal radiation. As Planck's law describes, every physical body spontaneously and continuously emits electromagnetic radiation.

Thermal radiation is electromagnetic radiation emitted by the thermal motion of particles in matter. Thermal radiation transmits as an electromagnetic wave through both matter and vacuum. When matter absorbs thermal radiation its temperature will tend to rise. All matter with a temperature greater than absolute zero emits thermal radiation. The emission of energy arises from a combination of electronic, molecular, and lattice oscillations in a material. Kinetic energy is converted to electromagnetism due to charge-acceleration or dipole oscillation. At room temperature, most of the emission is in the infrared (IR) spectrum. Thermal radiation is one of the fundamental mechanisms of heat transfer, along with conduction and convection.

The R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat, in the context of construction. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions. The measure is therefore equally relevant for lowering energy bills for heating in the winter, for cooling in the summer, and for general comfort.

Infrared thermography (IRT), thermal video or thermal imaging, is a process where a thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are examples of infrared imaging science. Thermographic cameras usually detect radiation in the long-infrared range of the electromagnetic spectrum and produce images of that radiation, called thermograms. Since infrared radiation is emitted by all objects with a temperature above absolute zero according to the black body radiation law, thermography makes it possible to see one's environment with or without visible illumination. The amount of radiation emitted by an object increases with temperature; therefore, thermography allows one to see variations in temperature. When viewed through a thermal imaging camera, warm objects stand out well against cooler backgrounds; humans and other warm-blooded animals become easily visible against the environment, day or night. As a result, thermography is particularly useful to the military and other users of surveillance cameras.

In heat transfer, Kirchhoff's law of thermal radiation refers to wavelength-specific radiative emission and absorption by a material body in thermodynamic equilibrium, including radiative exchange equilibrium. It is a special case of Onsager reciprocal relations as a consequence of the time reversibility of microscopic dynamics, also known as microscopic reversibility.

Black-body radiation is the thermal electromagnetic radiation within, or surrounding, a body in thermodynamic equilibrium with its environment, emitted by a black body. It has a specific, continuous spectrum of wavelengths, inversely related to intensity, that depend only on the body's temperature, which is assumed, for the sake of calculations and theory, to be uniform and constant.

A radiant barrier is a type of building material that reflects thermal radiation and reduces heat transfer. Because thermal energy is also transferred by conduction and convection, in addition to radiation, radiant barriers are often supplemented with thermal insulation that slows down heat transfer by conduction or convection.

The emissivity of the surface of a material is its effectiveness in emitting energy as thermal radiation. Thermal radiation is electromagnetic radiation that most commonly includes both visible radiation (light) and infrared radiation, which is not visible to human eyes. A portion of the thermal radiation from very hot objects is easily visible to the eye.

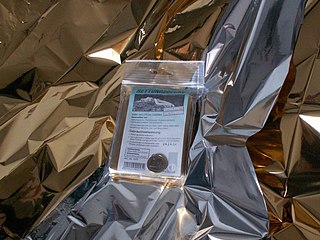

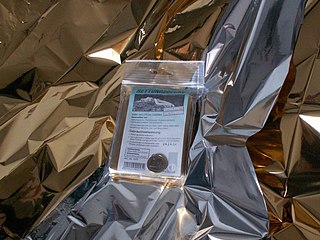

A space blanket is an especially low-weight, low-bulk blanket made of heat-reflective thin plastic sheeting. They are used on the exterior surfaces of spacecraft for thermal control, as well as by people. Their design reduces the heat loss in a person's body, which would otherwise occur quickly due to thermal radiation, water evaporation, or convection. Their low weight and compact size before unfurling make them ideal when space or weight are at a premium. They may be included in first aid kits and with camping equipment. Lost campers and hikers have an additional possible benefit: the shiny surface flashes in the sun, allowing its use as an improvised distress beacon for searchers and as a method of signalling over long distances to other people.

Building insulation is material used in a building to reduce the flow of thermal energy. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation. Often an insulation material will be chosen for its ability to perform several of these functions at once.

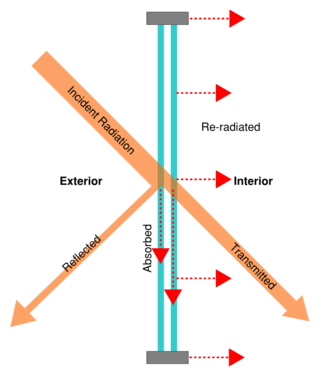

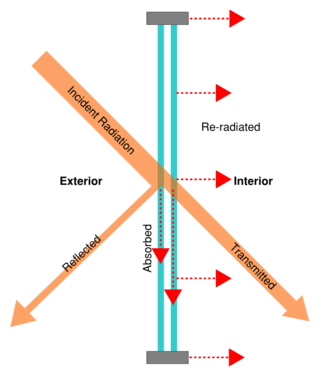

Solar gain is the increase in thermal energy of a space, object or structure as it absorbs incident solar radiation. The amount of solar gain a space experiences is a function of the total incident solar irradiance and of the ability of any intervening material to transmit or resist the radiation.

Insulative paints, or insulating paints, are a specially designed type of paint in which can be used to coat a surface to reduce heat transfer as well as increase the thermal insulating property (R-value in order to aid cooling and heating efforts for example.Insulative paints use a technology where a broad spectrum thermally reflective coating is applied to a specific type of micro-spheres to block heat radiation in a larger range of thermal energy to dissipate heat rapidly. This type of coated thermally reflective material reduces heat transfer through the coating with 90% of solar infrared radiation and 85% of ultraviolet radiation being radiated back from the coated surface[1]

Building insulation materials are the building materials that form the thermal envelope of a building or otherwise reduce heat transfer.

An infrared heater or heat lamp is a heating appliance containing a high-temperature emitter that transfers energy to a cooler object through electromagnetic radiation. Depending on the temperature of the emitter, the wavelength of the peak of the infrared radiation ranges from 750 nm to 1 mm. No contact or medium between the emitter and cool object is needed for the energy transfer. Infrared heaters can be operated in vacuum or atmosphere.

Interior Radiation Control Coating Systems (IRCCS), sometimes referred to as radiant barrier coatings, are paints designed to provide thermal insulation to buildings.

Window insulation reduces heat transfer from one side of a window to the other. The U-value is used to refer to the amount of heat that can pass through a window, called thermal transmittance, with a lower score being better. The U-factor of a window can often be found on the rating label of the window.

Glazing, which derives from the Middle English for 'glass', is a part of a wall or window, made of glass. Glazing also describes the work done by a professional "glazier". Glazing is also less commonly used to describe the insertion of ophthalmic lenses into an eyeglass frame.

Insulating glass (IG) consists of two or more glass window panes separated by a space to reduce heat transfer across a part of the building envelope. A window with insulating glass is commonly known as double glazing or a double-paned window, triple glazing or a triple-paned window, or quadruple glazing or a quadruple-paned window, depending upon how many panes of glass are used in its construction.