A Bailey bridge is a type of portable, pre-fabricated, truss bridge. It was developed in 1940–1941 by the British for military use during the Second World War and saw extensive use by British, Canadian and American military engineering units. A Bailey bridge has the advantages of requiring no special tools or heavy equipment to assemble. The wood and steel bridge elements were small and light enough to be carried in trucks and lifted into place by hand, without the use of a crane. The bridges were strong enough to carry tanks. Bailey bridges continue to be used extensively in civil engineering construction projects and to provide temporary crossings for pedestrian and vehicle traffic. A Bailey bridge and its construction were prominently featured in the 1977 film A Bridge Too Far.

A pontoon bridge, also known as a floating bridge, uses floats or shallow-draft boats to support a continuous deck for pedestrian and vehicle travel. The buoyancy of the supports limits the maximum load that they can carry.

The Blue Water Bridge is a twin-span international bridge across the St. Clair River that links Port Huron, Michigan, United States, and Sarnia, Ontario, Canada. The Blue Water Bridge connects Highway 402 in Ontario with both Interstate 69 (I-69) and Interstate 94 (I-94) in Michigan.

A cantilever bridge is a bridge built using structures that project horizontally into space, supported on only one end. For small footbridges, the cantilevers may be simple beams; however, large cantilever bridges designed to handle road or rail traffic use trusses built from structural steel, or box girders built from prestressed concrete.

Beam bridges are the simplest structural forms for bridge spans supported by an abutment or pier at each end. No moments are transferred throughout the support, hence their structural type is known as simply supported.

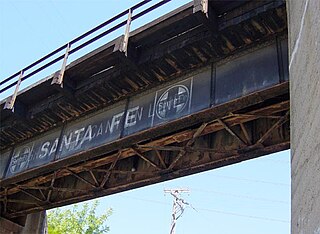

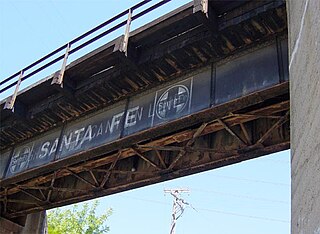

A plate girder bridge is a bridge supported by two or more plate girders.

A box girder bridge, or box section bridge, is a bridge in which the main beams comprise girders in the shape of a hollow box. The box girder normally comprises prestressed concrete, structural steel, or a composite of steel and reinforced concrete. The box is typically rectangular or trapezoidal in cross-section. Box girder bridges are commonly used for highway flyovers and for modern elevated structures of light rail transport. Although the box girder bridge is normally a form of beam bridge, box girders may also be used on cable-stayed and other bridges.

The Howrah Bridge is a balanced cantilever bridge over the Hooghly River in West Bengal. Commissioned in 1943, the bridge was originally named the New Howrah Bridge, because it replaced a pontoon bridge at the same location linking the cities of Howrah and Kolkata (Calcutta). On 14 June 1965, it was renamed Rabindra Setu after the great Bengali poet Rabindranath Tagore, who was the first Indian and Asian Nobel laureate. It is still popularly known as the Howrah Bridge.

The Medium Girder Bridge (MGB) is a lightweight, man portable bridge and can be assembled without help from heavy equipment. In addition, it is also a deck type, two-girder bridging system capable of carrying loads up to and including Main battle tanks (MBT).

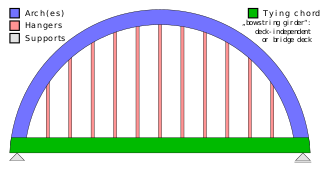

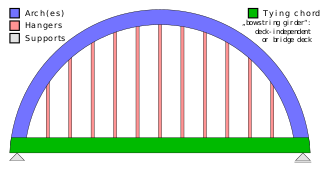

A tied-arch bridge is an arch bridge in which the outward horizontal forces of the arch(es) caused by tension at the arch ends to a foundation are countered by equal tension of its own gravity plus any element of the total deck structure such great arch(es) support. The arch(es) have strengthened chord(s) that run to a strong part of the deck structure or to independent tie-rods below the arch ends.

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridges are plate and box.

A Howe truss is a truss bridge consisting of chords, verticals, and diagonals whose vertical members are in tension and whose diagonal members are in compression. The Howe truss was invented by William Howe in 1840, and was widely used as a bridge in the mid to late 1800s.

A deck is the surface of a bridge. A structural element of its superstructure, it may be constructed of concrete, steel, open grating, or wood. Sometimes the deck is covered by a railroad bed and track, asphalt concrete, or other form of pavement for ease of vehicle crossing. A concrete deck may be an integral part of the bridge structure or it may be supported with I-beams or steel girders.

Floats are airtight hollow structures, similar to pressure vessels, designed to provide buoyancy in water. Their principal applications are in watercraft hulls, aircraft floats, floating pier, pontoon rhinos, pontoon causeways, and marine engineering applications such as salvage.

The Hadley Parabolic Bridge, often referred to locally as the Hadley Bow Bridge, carries Corinth Road across the Sacandaga River in Hadley, New York, United States. It is an iron bridge dating from the late 19th century.

The Callender-Hamilton bridge is a modular portable pre-fabricated truss bridge. It is primarily designed for use as permanent civil bridging as well as for emergency bridge replacement and for construction by military engineering units. Assembling a Callender-Hamilton bridge takes much longer than the more familiar Bailey bridge as it is made up of individual lengths of galvanised steel bolted together with galvanised high-strength steel bolts, all of which require torque settings. It is stronger and simpler in design concept than the Bailey bridge.

The Maslenica Bridge is a deck arch bridge carrying the D8 state road spanning the Novsko Ždrilo strait of the Adriatic Sea approximately 1 km (0.62 mi) to the west of the settlement of Maslenica, Croatia and 500 m (1,600 ft) south of the D54 and D8 state roads junction. It was built in 2005 on a site of a similar bridge that was destroyed in 1991, during the Croatian War of Independence.

This is a list of bridging and trackway equipment used by the Royal Engineers of the British Army. For more equipment in use with the Royal Engineers, see Modern equipment of the British Army.

The State Street Bridge, also known as the Fort Road Bridge or the Bridgeport Bridge, is a bridge carrying State Street over the Cass River in Bridgeport, Michigan, United States. It was listed on the National Register of Historic Places in 1995.

The Loddon Bridge disaster was a collapse of falsework during construction of a reinforced concrete deck on the Loddon Bridge of the A329(M) motorway in Berkshire, England, on 24 October 1972. It killed three people and injured ten others. It is thought that a design error led part of the falsework, transitioning between the deck and the supporting towers, to be understrength and it failed by buckling or twisting. The part-poured deck fell into the river below. The collapse was investigated by Her Majesty's Factory Inspectorate and the contractor, Marples Ridgway pled guilty to a breach of the construction regulations at a trial in Bracknell, being fined £150.