Related Research Articles

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide, in various ratios. The gas often contains some carbon dioxide and methane. It is principly used for producing ammonia or methanol. Syngas is combustible and can be used as a fuel. Historically, it has been used as a replacement for gasoline, when gasoline supply has been limited; for example, wood gas was used to power cars in Europe during WWII.

Gasification is a process that converts biomass- or fossil fuel-based carbonaceous materials into gases, including as the largest fractions: nitrogen (N2), carbon monoxide (CO), hydrogen (H2), and carbon dioxide (CO2). This is achieved by reacting the feedstock material at high temperatures (typically >700 °C), without combustion, via controlling the amount of oxygen and/or steam present in the reaction. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel due to the flammability of the H2 and CO of which the gas is largely composed. Power can be derived from the subsequent combustion of the resultant gas, and is considered to be a source of renewable energy if the gasified compounds were obtained from biomass feedstock.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

Alternative fuel, known as non-conventional and advanced fuels, are any materials or substances that can be used as fuels, other than conventional fuels like; fossil fuels, as well as nuclear materials such as uranium and thorium, as well as artificial radioisotope fuels that are made in nuclear reactors.

The hydrogen economy is using hydrogen to decarbonize economic sectors which are hard to electrify, essentially, the "hard-to-abate" sectors such as cement, steel, long-haul transport etc. In order to phase out fossil fuels and limit climate change, hydrogen can be created from water using renewable sources such as wind and solar, and its combustion only releases water vapor to the atmosphere.

Hydrogen fuel refers to hydrogen which is burned as fuel with oxygen. It is zero-carbon, provided that it is created in a process that does not involve carbon. It can be used in fuel cells or internal combustion engines. Regarding hydrogen vehicles, hydrogen has begun to be used in commercial fuel cell vehicles such as passenger cars, and has been used in fuel cell buses for many years. It is also used as a fuel for spacecraft propulsion.

High-temperature electrolysis is a technology for producing hydrogen from water at high temperatures.

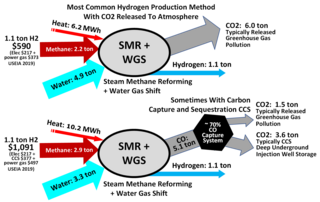

Steam reforming or steam methane reforming (SMR) is a method for producing syngas by reaction of hydrocarbons with water. Commonly natural gas is the feedstock. The main purpose of this technology is hydrogen production. The reaction is represented by this equilibrium:

The Sabatier reaction or Sabatier process produces methane and water from a reaction of hydrogen with carbon dioxide at elevated temperatures and pressures in the presence of a nickel catalyst. It was discovered by the French chemists Paul Sabatier and Jean-Baptiste Senderens in 1897. Optionally, ruthenium on alumina makes a more efficient catalyst. It is described by the following exothermic reaction.

Artificial photosynthesis is a chemical process that biomimics the natural process of photosynthesis to convert sunlight, water, and carbon dioxide into carbohydrates and oxygen. The term artificial photosynthesis is commonly used to refer to any scheme for capturing and storing the energy from sunlight in the chemical bonds of a fuel. Photocatalytic water splitting converts water into hydrogen and oxygen and is a major research topic of artificial photosynthesis. Light-driven carbon dioxide reduction is another process studied that replicates natural carbon fixation.

A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or natural gas, to produce electricity. Fossil fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical generator. The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine. All plants use the energy extracted from the expansion of a hot gas, either steam or combustion gases. Although different energy conversion methods exist, all thermal power station conversion methods have their efficiency limited by the Carnot efficiency and therefore produce waste heat.

An integrated gasification combined cycle (IGCC) is a technology using a high pressure gasifier to turn coal and other carbon based fuels into pressurized gas—synthesis gas (syngas). It can then remove impurities from the syngas prior to the electricity generation cycle. Some of these pollutants, such as sulfur, can be turned into re-usable byproducts through the Claus process. This results in lower emissions of sulfur dioxide, particulates, mercury, and in some cases carbon dioxide. With additional process equipment, a water-gas shift reaction can increase gasification efficiency and reduce carbon monoxide emissions by converting it to carbon dioxide. The resulting carbon dioxide from the shift reaction can be separated, compressed, and stored through sequestration. Excess heat from the primary combustion and syngas fired generation is then passed to a steam cycle, similar to a combined cycle gas turbine. This process results in improved thermodynamic efficiency compared to conventional pulverized coal combustion.

Hydrogen production is the family of industrial methods for generating hydrogen gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming of natural gas and other light hydrocarbons, partial oxidation of heavier hydrocarbons, and coal gasification. Other methods of hydrogen production include biomass gasification, zero-CO2-emission methane pyrolysis, and electrolysis of water. The latter processes, methane pyrolysis as well as water electrolysis can be done directly with any source of electricity, such as solar power.

A water-fuelled car is an automobile that hypothetically derives its energy directly from water. Water-fuelled cars have been the subject of numerous international patents, newspaper and popular science magazine articles, local television news coverage, and websites. The claims for these devices have been found to be pseudoscience and some were found to be tied to investment frauds. These vehicles may be claimed to produce fuel from water on board with no other energy input, or may be a hybrid claiming to derive some of its energy from water in addition to a conventional source.

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but has since also been applied to other sources of heat energy, such as nuclear energy.

A solar fuel is a synthetic chemical fuel produced from solar energy. Solar fuels can be produced through photochemical, photobiological, thermochemical, and electrochemical reactions. Light is used as an energy source, with solar energy being transduced to chemical energy, typically by reducing protons to hydrogen, or carbon dioxide to organic compounds.

Carbon-neutral fuel is fuel which produces no net-greenhouse gas emissions or carbon footprint. In practice, this usually means fuels that are made using carbon dioxide (CO2) as a feedstock. Proposed carbon-neutral fuels can broadly be grouped into synthetic fuels, which are made by chemically hydrogenating carbon dioxide, and biofuels, which are produced using natural CO2-consuming processes like photosynthesis.

Power-to-gas is a technology that uses electric power to produce a gaseous fuel. When using surplus power from wind generation, the concept is sometimes called windgas.

E-diesel is a synthetic diesel fuel created by Audi for use in automobiles. Currently, e-diesel is created by an Audi research facility in partnership with a company named Sunfire. The fuel is created from carbon dioxide, water, and electricity with a process powered by renewable energy sources to create a liquid energy carrier called blue crude which is then refined to generate e-diesel. E-diesel is considered to be a carbon-neutral fuel as it does not extract new carbon and the energy sources to drive the process are from carbon-neutral sources. As of April 2015, an Audi A8 driven by Federal Minister of Education and Research in Germany is using the e-diesel fuel.

References

- 1 2 3 "CO2-Free Engine Powers Up", Mitsubishi website

- 1 2 3 "Clean Magnesium Energy Cycle Hints at Fossil Fuel Freedom", by Steve Levenstein, July 27, 2007, InventorSpot.com

- 1 2 3 4 5 "TIT & Mitsubishi Prototypes Pollution-free Engine Excluding Fossil Fuel", by Motohiko Hamada and Nikkei Monozukuri, techon.nikkeibp.co.jp

- 1 2 Duncan Graham-Rowe (September 19, 2007). "Solar-Powered Laser". MIT Technology Review .

- ↑ Applied Physics Letters (2007), cited in [4]