Masonry is the craft of building a structure with brick, stone, or similar material, including mortar plastering which are often laid in, bound, and pasted together by mortar. The term masonry can also refer to the building units themselves.

A roof is the top covering of a building, including all materials and constructions necessary to support it on the walls of the building or on uprights, providing protection against rain, snow, sunlight, extremes of temperature, and wind. A roof is part of the building envelope.

Reinforced concrete, also called ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars (rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion.

An earth shelter, also called an earth house, earth bermed house, or underground house, is a structure with earth (soil) against the walls, on the roof, or that is entirely buried underground.

A floor is the bottom surface of a room or vehicle. Floors vary from simple dirt in a cave to many layered surfaces made with modern technology. Floors may be stone, wood, bamboo, metal or any other material that can support the expected load.

A geodesic dome is a hemispherical thin-shell structure (lattice-shell) based on a geodesic polyhedron. The rigid triangular elements of the dome distribute stress throughout the structure, making geodesic domes able to withstand very heavy loads for their size.

Building material is material used for construction. Many naturally occurring substances, such as clay, rocks, sand, wood, and even twigs and leaves, have been used to construct buildings and other structures, like bridges. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

A concrete block, also known as a cinder block in North American English, breeze block in British English, concrete masonry unit (CMU), or by various other terms, is a standard-size rectangular block used in building construction. The use of blockwork allows structures to be built in the traditional masonry style with layers of staggered blocks.

This page is a list of construction topics.

A concrete shell, also commonly called thin shell concrete structure, is a structure composed of a relatively thin shell of concrete, usually with no interior columns or exterior buttresses. The shells are most commonly monolithic domes, but may also take the form of hyperbolic paraboloids, ellipsoids, cylindrical sections, or some combination thereof. The first concrete shell dates back to the 2nd century.

Insulating concrete form or insulated concrete form (ICF) is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs. The forms are interlocking modular units that are dry-stacked and filled with concrete. The units lock together somewhat like Lego bricks and create a form for the structural walls or floors of a building. ICF construction has become commonplace for both low rise commercial and high performance residential construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

The Xanadu Houses were a series of experimental homes built to showcase examples of computers and automation in the home in the United States. The architectural project began in 1979, and during the early 1980s three houses were built in different parts of the US: one each in Kissimmee, Florida; Wisconsin Dells, Wisconsin; and Gatlinburg, Tennessee. The houses included novel construction and design techniques, and became popular tourist attractions during the 1980s.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels, floors, roofs, and piles. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

Concrete cover, in reinforced concrete, is the least distance between the surface of embedded reinforcement and the outer surface of the concrete. The concrete cover depth can be measured with a cover meter. The purpose of concrete cover is to protect the reinforcement from corrosion, fire, and other potential damage.

Building insulation materials are the building materials that form the thermal envelope of a building or otherwise reduce heat transfer.

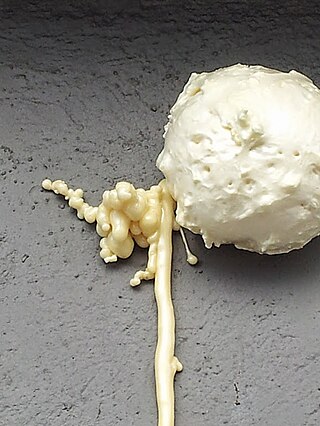

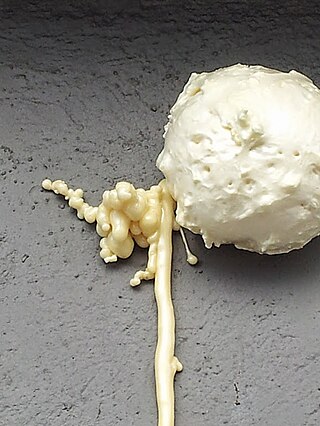

Spray foam is a chemical product created by a chemical reaction of two component parts, commonly referred to as side A and side B. Side A contains very reactive chemicals known as isocyanate. Side B contains a polyol, which reacts with isocyanates to make polyurethane, and a mixture of other chemicals, including catalysts, flame retardant, blowing agents and surfactants. These react when mixed with each other and expand up to 30-60 times its liquid volume after it is sprayed in place. This expansion makes it useful as a specialty packing material which forms to the shape of the product being packaged and produces a high thermal insulating value with virtually no air infiltration.

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs.

A Rigid-frame bridge is a bridge in which the superstructure and substructure are rigidly connected to act as a continuous unit. Typically, the structure is cast monolithically, making the structure continuous from deck to foundation. The connections between members are rigid connections which transfer bending moment, axial forces, and shear forces. A bridge design consisting of a rigid frame can provide significant structural benefits, but can also be difficult to design and/or construct.