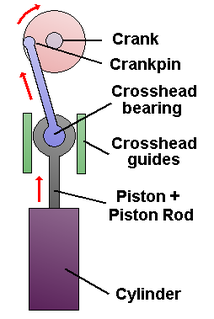

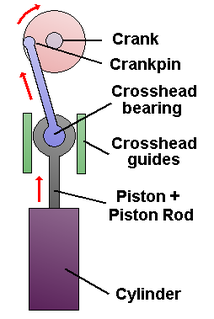

A crankshaft is a shaft driven by a crank mechanism consisting of a series of cranks and crankpins to which the connecting rods of an engine is attached. It is a mechanical part able to perform a conversion between reciprocating motion and rotational motion. In a reciprocating engine, it translates reciprocating motion of the piston into rotational motion, whereas in a reciprocating compressor, it converts the rotational motion into reciprocating motion. In order to do the conversion between two motions, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

A crosshead is a mechanism used as part of the slider-crank linkages of long reciprocating engines and reciprocating compressors to eliminate sideways pressure on the piston. Also, the crosshead enables the connecting rod to freely move outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston was attached directly to the connecting rod like on trunk engines. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine.

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing gear. It is sometimes referred to as the "motion".

A connecting rod is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end.

A compound steam engine unit is a type of steam engine where steam is expanded in two or more stages. A typical arrangement for a compound engine is that the steam is first expanded in a high-pressure (HP) cylinder, then having given up heat and losing pressure, it exhausts directly into one or more larger-volume low-pressure (LP) cylinders. Multiple-expansion engines employ additional cylinders, of progressively lower pressure, to extract further energy from the steam.

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or the driving wheels.

Engine balance refers to how the forces are balanced within an internal combustion engine or steam engine. The most commonly used terms are primary balance and secondary balance. First-order balance and second-order balance are also used. Unbalanced forces within the engine can lead to vibrations.

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth linear motion. It is found in a wide range of mechanisms, including reciprocating engines and pumps. The two opposite motions that comprise a single reciprocation cycle are called strokes.

A crankpin is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod.

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC).

Cyldon was the brand name for a range of model stationary steam engines, manufactured in Enfield, Middlesex, England between 1947 and 1951 by Sydney S Bird & Sons. The name Cyldon was an amalgamation of Sydney Bird's two son's names Cyril and Donald.

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their last years of large-scale manufacture during World War II. Reciprocating steam engines were progressively replaced in marine applications during the 20th century by steam turbines and marine diesel engines.

A big bang engine is an unconventional engine designed so that some of the power strokes occur simultaneously or in close succession. This is achieved by changing the ignition timing, changing or re-timing the camshaft, and sometimes in combination with a change in crankpin angle. The goal is to change the power delivery characteristics of the engine. A regular firing multi-cylinder engine fires at approximately even intervals, giving a smooth-running engine. Because a big-bang engine has uneven power delivery, they tend to run rougher and generate more vibration than an even-firing engine.

A barring engine is a small engine that forms part of the installation of a large engine, and is used to turn the main engine to a favourable position from which it can be started. If the main engine has stopped close to its dead centre it is unable to restart itself. Barring may also be done to turn the engine over slowly (unloaded) for maintenance, or to prevent belt drives being left too long in one position and taking a "set".

Grasshopper beam engines are beam engines that are pivoted at one end, rather than in the centre.

A return connecting rod, return piston rod or double piston rod engine or back-acting engine is a particular layout for a steam engine.

High-speed steam engines were one of the final developments of the stationary steam engine. They ran at a high speed, of several hundred rpm, which was needed by tasks such as electricity generation.

The Willans engine or central valve engine was a high-speed stationary steam engine used mainly for electricity generation around the start of the 20th century.

The Cyclone Waste Heat Engine (WHE) is a small steam engine developed to produce power from steam created from waste heat. It is an offshoot of the development of the Cyclone Mark V Engine by the company Cyclone Power Technologies of Pompano Beach, Florida. The original versions were designed by inventor Harry Schoell, founder of Cyclone Power Technologies and the later versions have been designed by the Ohio State University Center for Automotive Research (OSU-CAR).

Stuart Turner Ltd is a British engineering company, based in Henley-on-Thames, Oxfordshire, England, founded by engineer Sidney Marmaduke Stuart Turner in 1906.