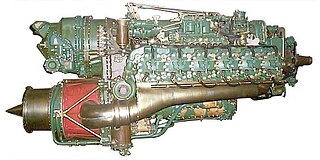

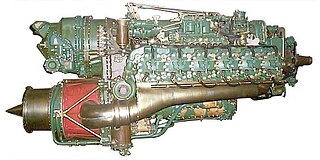

The Napier Nomad was a British diesel aircraft engine designed and built by Napier & Son in 1949. They combined a piston engine with a turbine to recover energy from the exhaust and thereby improve fuel economy. Two versions were tested, the complex Nomad I which used two propellers, each driven by the mechanically independent stages, and the Nomad II, using the turbo-compound principle, coupled the two parts to drive a single propeller. The Nomad II had the lowest specific fuel consumption figures seen up to that time. Despite this the Nomad project was cancelled in 1955 having spent £5.1 million on development, as most interest had passed to turboprop designs.

The Junkers Jumo 205 aircraft engine was the most famous of a series of aircraft diesel engines that were the first, and for more than half a century, the only successful aviation diesel powerplants. The Jumo 204 first entered service in 1932. Later engines of this type comprised the experimental Jumo 206 and Jumo 208, with the Jumo 207 produced in some quantity for the Junkers Ju 86P and -R high-altitude reconnaissance aircraft, and the 46-meter wingspan, six-engined Blohm & Voss BV 222 Wiking flying boat. All three of these variants differed in stroke and bore and supercharging arrangements. In all, more than 900 of these engines were produced, in the 1930s and through most of World War II.

The Jumo 222 was a German high-power multiple-bank in-line piston aircraft engine from Junkers, designed under the management of Ferdinand Brandner of the Junkers Motorenwerke.

The Junkers Jumo 204 was the second in a series of German aircraft Diesel engines. The Jumo 204 first entered service in 1932. Later engines in the series were designated Jumo 205, Jumo 206, Jumo 207 and Jumo 208, they differed in stroke and bore and supercharging arrangements.

The Jumo 211 was a German inverted V-12 aircraft engine, Junkers Motoren's primary aircraft engine of World War II. It was the direct competitor to the Daimler-Benz DB 601 and closely paralleled its development. While the Daimler-Benz engine was mostly used in single-engined and twin-engined fighters, the Jumo engine was primarily used in bombers such as Junkers' own Ju 87 and Ju 88, and Heinkel's H-series examples of the Heinkel He 111 medium bomber. It was the most-produced German aero engine of the war, with almost 70,000 examples completed.

The Jumo 210 was Junkers Motoren's first production inverted V12 gasoline aircraft engine, first produced in the early-1930s. Depending on the version it produced between 610 and 730 PS and can be considered a counterpart of the Rolls-Royce Kestrel in many ways. Although originally intended to be used in almost all pre-war designs, rapid progress in aircraft design quickly relegated it to the small end of the power scale by the late 1930s. Almost all aircraft designs switched to the much larger Daimler-Benz DB 600, so the 210 was produced only for a short time before Junkers responded with a larger engine of their own, the Junkers Jumo 211.

The Kestrel or type F is a 22-litre 700-horsepower (520 kW) class V-12 aircraft engine from Rolls-Royce, their first cast-block engine and the pattern for most of their future piston-engine designs. Used during the interwar period, it provided excellent service on a number of British fighters and bombers of the era, such as the Hawker Fury and Hawker Hart family, and the Handley Page Heyford. The engine also sold to international air forces, and it was even used to power prototypes of German military aircraft types that were later used during the Battle of Britain. Several Kestrel engines remain airworthy today.

The Rolls-Royce Eagle Mk XXII was a British 24-cylinder, sleeve valve, H-block aero engine of 46 litre displacement. It was designed and built in the early-1940s by Rolls-Royce Limited and first ran in 1944. It was liquid-cooled, of flat H configuration with two crankshafts and was capable of 3,200 horsepower at 18 psi boost.

The Rolls-Royce Condor aircraft piston engine was a larger version of the Rolls-Royce Eagle developing up to 675 horsepower (500 kW). The engine first ran in 1918 and a total of 327 engines were recorded as being built.

The aircraft diesel engine or aero diesel is a diesel-powered aircraft engine. They were used in airships and tried in aircraft in the late 1920s and 1930s, but never widely adopted beyond this. Their main advantages are their excellent specific fuel consumption, the reduced flammability and somewhat higher density of their fuel, but these have been outweighed by a combination of inherent disadvantages compared to gasoline-fueled or turboprop engines. The ever-rising cost of avgas and doubts about its future availability have spurred a resurgence in aircraft diesel engine production in the early 2010s.

The Rolls-Royce Exe, or Boreas, was a 24-cylinder air-cooled X block sleeve valve aircraft engine intended primarily for the new Fairey Fleet Air Arm aircraft, particularly the Fairey Barracuda. The Exe was relatively powerful for its era, producing about 1,100 hp (820 kW). This is notable given the relatively small 22 litres (1,300 cu in) displacement, the Merlin requiring 27 litres for approximately the same power level. The X-24 layout made this quite a compact engine.

The Napier Dagger was a 24-cylinder H-pattern (or H-Block) air-cooled engine designed by Frank Halford and built by Napier before World War II. It was a development of the earlier Napier Rapier.

The Napier Rapier was a British 16-cylinder H pattern air-cooled aero engine designed by Frank Halford and built by Napier & Son shortly before World War II.

The Napier Cub was an unusual and very large experimental 1,000 horsepower (750 kW) 16-cylinder 'X' pattern liquid-cooled aero engine built by the British engine company D. Napier & Son. The Cub was the only Napier 'X' engine design. First flown on 15 December 1922 in an Avro Aldershot biplane bomber aircraft, the only other application was in the Blackburn Cubaroo. Only six engines of this type were ordered and produced.

The Napier Javelin was a British six-cylinder inline air-cooled engine designed by Frank Halford and built by D. Napier & Son. First flown in March 1934 in the prototype of the Percival Mew Gull racing aircraft, the engine was also used in the Spartan Arrow biplane and the Percival Gull.

The Wolseley 60 hp or Type C was a British liquid-cooled V-8 aero engine that first ran in 1910, it was designed and built by Wolseley Motors. The engine featured water-cooled exhaust ports and employed a 20 lb (9 kg) flywheel. During an official four-hour test the engine produced an average of 55 horsepower. A larger capacity variant known as the 80 hp or Type B used an internal camshaft and propeller reduction gear.

The Junkers L1 was the first engine manufactured by Junkers to fly. It was an air-cooled, upright 6-cylinder inline 4-stroke petrol engine only produced in small numbers and largely used for research, but led to the successful L5 and its V-12 development, the L55.

The Diesel Air Dair 100 is an opposed-piston diesel aircraft engine, designed and produced by Diesel Air Ltd of Olney, Buckinghamshire for use in airships, home-built kitplanes and light aircraft. The prototype was built in the 1990s and exhibited it at PFA airshows. Although Diesel Air engines have been fitted to an AT-10 airship and to a Luscombe 8A monoplane, production numbers have been very limited.

The Superior Air Parts Gemini Diesel 100 is a diesel aircraft engine, under development by Superior Air Parts of Coppell, Texas, United States for use in homebuilt aircraft.

The Superior Air Parts Gemini Diesel 125 is a diesel aircraft engine, under development by Superior Air Parts of Coppell, Texas, United States for use in homebuilt aircraft.