A two-strokeengine is a type of internal combustion engine that completes a power cycle with two strokes of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust functions occurring at the same time.

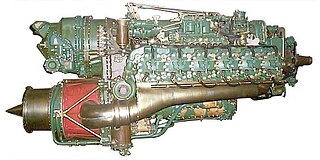

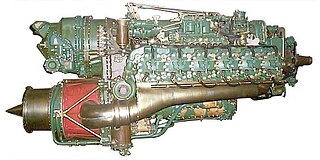

The Napier Nomad is a British diesel aircraft engine designed and built by Napier & Son in 1949. They combined a piston engine with a turbine to recover energy from the exhaust and thereby improve fuel economy. Two versions were tested, the complex Nomad I which used two propellers, each driven by the mechanically independent stages, and the Nomad II, using the turbo-compound principle, coupled the two parts to drive a single propeller. The Nomad II had the lowest specific fuel consumption figures seen up to that time. Despite this the Nomad project was cancelled in 1955 having spent £5.1 million on development, as most interest had passed to turboprop designs.

The Napier Deltic engine is a British opposed-piston valveless, supercharged uniflow scavenged, two-stroke diesel engine used in marine and locomotive applications, designed and produced by D. Napier & Son. Unusually, the cylinders were disposed in a three-bank triangle, with a crankshaft at each corner of the triangle.

An opposed-piston engine is a piston engine in which each cylinder has a piston at both ends, and no cylinder head. Petrol and diesel opposed-piston engines have been used mostly in large-scale applications such as ships, military tanks, and factories. Current manufacturers of opposed-piston engines include Cummins, Achates Power and Fairbanks-Morse Defense (FMDefense).

The Jumo 205 aircraft engine was the most famous of a series of aircraft diesel engines produced by Junkers. The Jumo 204 first entered service in 1932. Later engines of this type comprised the experimental Jumo 206 and Jumo 208, with the Jumo 207 produced in some quantity for the Junkers Ju 86P and -R high-altitude reconnaissance aircraft, and the 46-meter wingspan, six-engined Blohm & Voss BV 222 Wiking flying boat. All three of these variants differed in stroke and bore and supercharging arrangements. In all, more than 900 of these engines were produced, in the 1930s and through most of World War II.

The Junkers Jumo 223 was an experimental 24-cylinder aircraft engine based on the Junkers Jumo 205. Like the Jumo 205, it was an opposed piston two-stroke diesel engine. It had four banks of six cylinders in a rhomboid configuration, with four crankshafts, one at each vertex of the rhombus, and 48 pistons. It was designed for a power of 2,500 horsepower at 4,400 rpm, and weighed around 2,370 kg.

The Jumo 222 was a German high-power multiple-bank in-line piston aircraft engine from Junkers, designed under the management of Ferdinand Brandner of the Junkers Motorenwerke.

The Jumo 211 was a German inverted V-12 aircraft engine, Junkers Motoren's primary aircraft engine of World War II. It was the direct competitor to the Daimler-Benz DB 601 and closely paralleled its development. While the Daimler-Benz engine was mostly used in single-engined and twin-engined fighters, the Jumo engine was primarily used in bombers such as Junkers' own Ju 87 and Ju 88, and Heinkel's H-series examples of the Heinkel He 111 medium bomber. It was the most-produced German aero engine of the war, with almost 70,000 examples completed.

The Daimler-Benz DB 601 was a German aircraft engine built during World War II. It was a liquid-cooled inverted V12, and powered the Messerschmitt Bf 109, Messerschmitt Bf 110, and many others. Approximately 19,000 601's were produced before it was replaced by the improved Daimler-Benz DB 605 in 1942.

The aircraft diesel engine or aero diesel is a diesel-powered aircraft engine. They were used in airships and tried in aircraft in the late 1920s and 1930s, but were never widely adopted until recently. Their main advantages are their excellent specific fuel consumption, the reduced flammability and somewhat higher density of their fuel, but these have been outweighed by a combination of inherent disadvantages compared to gasoline-fueled or turboprop engines. The ever-rising cost of avgas and doubts about its future availability have spurred a resurgence in aircraft diesel engine production in the early 2010s.

The Hirth HM 504 is a four-cylinder air-cooled inverted inline engine. The HM 504 was a popular engine for light aircraft of the 1930s-1940s, and it was used to power a number of Germany's trainer aircraft of World War II. The engine featured a cast magnesium alloy crankcase made of Elektron The Hitachi Hatsukaze Model 11 was a Japanese licensed version.

A two-stroke diesel engine is a diesel engine that uses compression ignition in a two-stroke combustion cycle. It was invented by Hugo Güldner in 1899.

The Napier Culverin was a licensed built version of the Junkers Jumo 204 six-cylinder vertically opposed liquid-cooled diesel aircraft engine built by D. Napier & Son. The name is derived from the French word, culverin, for an early cannon or musket. First flown in 1938, the engine went into limited production, with testing carried out on a Blackburn Iris V biplane flying-boat aircraft and Fairey IIIF biplane.

The Daimler-Benz DB 602, originally known as Daimler-Benz LOF.6, was a German diesel cycle aero engine designed and built in the early 1930s. It was a liquid-cooled upright V16, and powered the two Hindenburg-class airships. It has roughly the same displacement and weight of the Beardmore Tornado, which was used in the ill-fated R101, but has almost twice the power of the Tornado, showing Daimler-Benz's superior knowledge regarding diesel engine construction.

The Commer TS3 was a diesel engine fitted in Commer trucks built by the Rootes Group in the 1950s and 1960s. It was the first diesel engine used by the company.

Sulzer ZG9 was a pre-World War II opposed-piston two-stroke diesel engine by Sulzer. The engine was available with a choice of two, three and four cylinders ; the two-cylinder version developed 120 bhp. It used a piston scavenge pump. This was mounted vertically above one rocker, driven by a bellcrank from the main rockers. This engine is sometimes cited as an inspiration for the Commer TS3 design.

The Hirth HM 512 was a 12-cylinder development of the earlier, 6-cylinder HM 506, produced in the late 1930s. Both were supercharged, inverted V, air-cooled engines.

The Michel engine was an unusual form of opposed-piston engine. It was unique in that its cylinders, instead of being open-ended cylinders containing two pistons, were instead joined in a Y-shape and had three pistons working within them.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

The Hirth HM 515 was a four-cylinder air-cooled inverted inline engine, intended to power light aircraft of the 1940s. Due to World War II, demand for the light aircraft to be powered by the HM 515 dried up and only the Siebel Si 202C Hummel was powered by development engines before further work was abandoned.