The BMW 801 was a powerful German 41.8-litre (2,550 cu in) air-cooled 14-cylinder-radial aircraft engine built by BMW and used in a number of German Luftwaffe aircraft of World War II. Production versions of the twin-row engine generated between 1,560 and 2,000 PS. It was the most produced radial engine of Germany in World War II with more than 61,000 built.

The Jumo 205 aircraft engine was the most numerous of a series of aircraft diesel engines produced by Junkers. The Jumo 204 first entered service in 1932. Later engines of this type comprised the experimental Jumo 206 and Jumo 208, with the Jumo 207 produced in some quantity for the Junkers Ju 86P and -R high-altitude reconnaissance aircraft, and the 46-meter wingspan, six-engined Blohm & Voss BV 222 Wiking flying boat. All three of these variants differed in stroke and bore and supercharging arrangements. In all, more than 900 of these engines were produced, in the 1930s and through most of World War II.

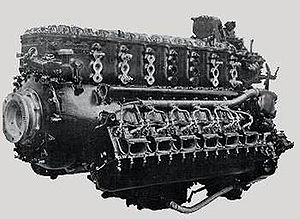

The Jumo 222 was a German high-power multiple-bank in-line piston aircraft engine from Junkers, designed under the management of Ferdinand Brandner of the Junkers Motorenwerke.

The Jumo 204 was an opposed-piston, inline, liquid-cooled 6-cylinder aircraft Diesel engine produced by the German manufacturer Junkers. It entered service in 1932. Later engines in the series, the Jumo 205, Jumo 206, Jumo 207 and Jumo 208, differed in stroke, bore, and supercharging arrangements.

The Jumo 211 was a German inverted V-12 aircraft engine, Junkers Motoren's primary aircraft engine of World War II. It was the direct competitor to the Daimler-Benz DB 601 and closely paralleled its development. While the Daimler-Benz engine was mostly used in single-engined and twin-engined fighters, the Jumo engine was primarily used in bombers such as Junkers' own Ju 87 and Ju 88, and Heinkel's H-series examples of the Heinkel He 111 medium bomber. It was the most-produced German aero engine of the war, with almost 70,000 examples completed.

The Daimler-Benz DB 601 was a German aircraft engine that was built during World War II. It was a liquid-cooled inverted V12, and powered the Messerschmitt Bf 109, Messerschmitt Bf 110, and many others. Approximately 19,000 601s were produced before it was replaced by the improved Daimler-Benz DB 605 in 1942.

A multi-valve or multivalve engine is one where each cylinder has more than two valves. A multi-valve engine has better breathing, and with more smaller valves may be able to operate at higher revolutions per minute (RPM) than a two-valve engine, delivering more power.

The Bramo 323 Fafnir is a nine-cylinder radial aircraft engine of the World War II era. Based heavily on Siemens/Bramo's earlier experience producing the Bristol Jupiter under licence, the Bramo 323 saw limited use.

The BMW 803 was a German aircraft engine, an attempt by BMW to build a high-output aircraft engine by coupling two BMW 801 engines back-to-back, driving contra-rotating propellers. The result was a 28-cylinder, four-row radial engine, each comprising a multiple-bank in-line engine with two cylinders in each bank, which, due to cooling concerns, were liquid cooled.

The BMW 802 was a large air-cooled radial aircraft engine, built using two rows of nine cylinders to produce what was essentially an 18-cylinder version of the 14-cylinder BMW 801. Although promising at first, development dragged on and the project was eventually cancelled to concentrate on jet engines instead.

The Junkers Jumo 213 was a World War II-era V-12 liquid-cooled aircraft engine, a development of Junkers Motoren's earlier design, the Jumo 211. The design added two features, a pressurized cooling system that required considerably less cooling fluid which allowed the engine to be built smaller and lighter, and a number of improvements that allowed it to run at higher RPM. These changes boosted power by over 500 hp and made the 213 one of the most sought-after Axis engine designs in the late-war era.

The BMW 132 was a nine-cylinder radial aircraft engine produced by BMW starting in 1933.

The Daimler-Benz DB 600 was a German aircraft engine designed and built before World War II as part of a new generation of German engine technology. It was a liquid-cooled inverted V12 engine, and powered the Messerschmitt Bf 110 and Heinkel He 111 among others.

The Lycoming XR-7755 was the largest piston aircraft engine ever built in the United States, with 36 cylinders totaling about 7,750 in3 (127 L) of displacement and a power output of 5,000 horsepower (3,700 kilowatts). It was originally intended to be used in the "European bomber" that eventually emerged as the Convair B-36. Only two examples were built before the project was terminated in 1946.

The Daimler-Benz DB 605 is a German aircraft engine built during World War II. Developed from the DB 601, the DB 605 was used from 1942 to 1945 in the Messerschmitt Bf 109 fighter, and the Bf 110 and Me 210C heavy fighters.

The Daimler-Benz DB 603 was a German aircraft engine used during World War II. It was a liquid-cooled 12-cylinder inverted V12 enlargement of the 33.9 Liter DB 601, which was in itself a development of the DB 600. Production of the DB 603 commenced in May 1942, and with a 44.5 liter displacement, was the largest displacement inverted V12 aircraft engine to be used in front line aircraft of the Third Reich during World War II.

The Daimler-Benz DB 600 series were a number of German aircraft engines designed and built before and during World War II as part of a new generation of German engine technology. The general layout was that of a liquid-cooled, inverted V12 engine. The design originated to a private venture project of Daimler-Benz, the F4 engine. Most newer DB engine designs used in WW2 were based around this engine.

The Junkers L88 was Junkers' first geared V-12 engine, appearing c.1930 and based on a pair of 6-cylinder L8s. In 1932 a supercharger was added. It was used in the world's second working pressurised aircraft, the Junkers Ju 49 and, for a while, in the large G 38 airliner and its Japanese built military version.

The Kawasaki Ha40, also known as the Army Type 2 1,100 hp Liquid Cooled In-line and Ha-60, was a license-built Daimler-Benz DB 601Aa 12-cylinder liquid-cooled inverted-vee aircraft engine. The Imperial Japanese Army Air Service (IJAAS) selected the engine to power its Kawasaki Ki-61 fighter.