George Westinghouse Jr. was a prolific American inventor, engineer, and entrepreneurial industrialist based in Pittsburgh, Pennsylvania who is best known for his creation of the railway air brake and for being a pioneer in the development and use of alternating current (AC) electrical power distribution. During his lifetime, he received 362 patents for his inventions and established 61 companies, many still in existence today.

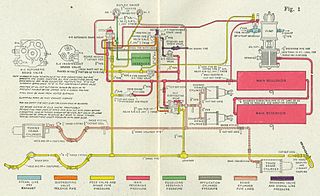

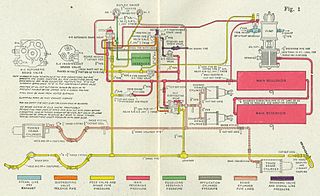

A railway air brake is a railway brake power braking system with compressed air as the operating medium. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on April 13, 1869. The Westinghouse Air Brake Company was subsequently organized to manufacture and sell Westinghouse's invention. In various forms, it has been nearly universally adopted.

Westinghouse may refer to:

In rail transport, distributed power (DP) is a generic term referring to the physical distribution—at intermediate points throughout the length of a train—of separate motive power groups. Such "groups" may be single units or multiple consists, and are remotely controlled from the leading locomotive. The practice allows locomotives to be placed anywhere within the length of a train when standard multiple-unit (MU) operation is impossible or impractical. DP can be achieved by wireless or wired (trainlined) means. Wired systems now provided by various suppliers use the cabling already extant throughout a train equipped with electronically controlled pneumatic brakes (ECP).

The vacuum brake is a braking system employed on trains and introduced in the mid-1860s. A variant, the automatic vacuum brake system, became almost universal in British train equipment and in countries influenced by British practice. Vacuum brakes also enjoyed a brief period of adoption in the United States, primarily on narrow-gauge railroads. Their limitations caused them to be progressively superseded by compressed air systems starting in the United Kingdom from the 1970s onward. The vacuum brake system is now obsolete; it is not in large-scale usage anywhere in the world, other than in South Africa, largely supplanted by air brakes.

A diesel locomotive is a type of railway locomotive in which the power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. The most common are diesel-electric locomotives and diesel-hydraulic.

Rail transport terms are a form of technical terminology applied to railways. Although many terms are uniform across different nations and companies, they are by no means universal, with differences often originating from parallel development of rail transport systems in different parts of the world, and in the national origins of the engineers and managers who built the inaugural rail infrastructure. An example is the term railroad, used in North America, and railway, generally used in English-speaking countries outside North America and by the International Union of Railways. In English-speaking countries outside the United Kingdom, a mixture of US and UK terms may exist.

A railway brake is a type of brake used on the cars of railway trains to enable deceleration, control acceleration (downhill) or to keep them immobile when parked. While the basic principle is similar to that on road vehicle usage, operational features are more complex because of the need to control multiple linked carriages and to be effective on vehicles left without a prime mover. Clasp brakes are one type of brakes historically used on trains.

Bendix Corporation is an American manufacturing and engineering company which, during various times in its existence, made automotive brake shoes and systems, vacuum tubes, aircraft brakes, aeronautical hydraulics and electric power systems, avionics, aircraft and automobile fuel control systems, radios, televisions and computers.

The Westinghouse Air Brake Technologies Corporation (WABCO) was an American company founded on September 28, 1869 by George Westinghouse in Pittsburgh, Pennsylvania. Earlier in the year he had invented the railway air brake in New York state.

Westinghouse Rail Systems Ltd was a British supplier of railway signalling and control equipment to the rail industry worldwide. Its head office was in Chippenham, Wiltshire, where it manufactured a variety of mechanical and electrical/electronic railway signalling equipment. It had six other UK offices in Croydon, York, Birmingham, Crawley, Swanley and Glasgow. It also had a number of overseas offices, particularly in the Far East, including Melbourne.

A magnetic track brake is a brake for rail vehicles. It consists of brake magnets, pole shoes, a suspension, a power transmission and, in the case of mainline railroads, a track rod. When current flows through the magnet coil, the magnet is attracted to the rail, which presses the pole shoes against the rail, thereby decelerating the vehicle.

The Westinghouse Brake & Signal Company Ltd was a British manufacturer of railroad signs. Founded by George Westinghouse, it was registered as "Westinghouse Brake Company" in 1881. The company reorganised in 1920, associating with Evans O'Donnell, and Saxby and Farmer which merged to form the "Westinghouse Brake & Saxby Signal Company". The 'Saxby' would be dropped from their title in 1935.

Knorr-Bremse AG is a German manufacturer of braking systems for rail and commercial vehicles that has operated since 1905. Other products in Group's portfolio include intelligent door systems, control components, air conditioning systems for rail vehicles, torsional vibration dampers, and transmission control systems for commercial vehicles.

Electronically controlled pneumatic brakes are a type of railway braking systems.

Theodor Georg Knorr was an engineer and entrepreneur on the field of railroad technology and founder of the company Knorr-Bremse. He is particularly remembered for his role in the development of the compressed air brake.

Haldex AB, also known as Haldex Group, is a Swedish company operating in the commercial vehicle industry. Haldex focuses on brake products, air suspension systems and products to enhance safety for heavy vehicles. The Foundation Brake product line includes brake products for wheel ends such as disc brakes, brake adjusters for drum brakes and actuators. Air Controls comprises products that improve the safety and driving dynamics of the brake system, such as compressed air dryers, valves, ABS and EBS.

The Kunze-Knorr brake is an automatic compressed-air brake for goods, passenger and express trains. It was the first graduated brake for goods trains in Europe. When it was introduced after the First World War, goods train brakes switched from hand operation to compressed-air in various European countries. The Deutsche Reichsbahn alone put the cost of equipping German goods wagons with Kunze-Knorr brakes between 1918 and 1927 at 478.4 million Reichsmarks. The operating cost savings from faster goods services and having fewer brakemen was assessed by the Reichsbahn at almost 96.3 million Reichsmark annually.

Upstate New York has been the setting for inventions and businesses of international significance. The abundance of water power and the advent of canal and rail transportation provided nineteenth century upstate New York entrepreneurs with the means to power factories and send their products to market. In the twentieth century, hydroelectric power and the New York State Thruway served the same roles. In April 2021, GlobalFoundries, a company specializing in the semiconductor industry, moved its headquarters from Silicon Valley, California to its most advanced semiconductor-chip manufacturing facility in Saratoga County, New York near a section of the Adirondack Northway, in Malta, New York.

Decelostat is a wheel slide protection system developed by Westinghouse Air Brake Company that is used in railroad cars to prevent over-braking that causes wheel-slide, a condition of reduction in friction between train wheels and rails. This low wheel/rail adhesion condition reduces braking performance and causes damage to wheels and the rails.