A bioreactor is any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow cells or tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.

The hydrogen cycle consists of hydrogen exchanges between biotic (living) and abiotic (non-living) sources and sinks of hydrogen-containing compounds.

Microbial metabolism is the means by which a microbe obtains the energy and nutrients it needs to live and reproduce. Microbes use many different types of metabolic strategies and species can often be differentiated from each other based on metabolic characteristics. The specific metabolic properties of a microbe are the major factors in determining that microbe's ecological niche, and often allow for that microbe to be useful in industrial processes or responsible for biogeochemical cycles.

Hydrogen gas is produced by several industrial methods. Nearly all of the world's current supply of hydrogen is created from fossil fuels. Most hydrogen is gray hydrogen made through steam methane reforming. In this process, hydrogen is produced from a chemical reaction between steam and methane, the main component of natural gas. Producing one tonne of hydrogen through this process emits 6.6–9.3 tonnes of carbon dioxide. When carbon capture and storage is used to remove a large fraction of these emissions, the product is known as blue hydrogen.

Microbial fuel cell (MFC) is a type of bioelectrochemical fuel cell system also known as micro fuel cell that generates electric current by diverting electrons produced from the microbial oxidation of reduced compounds on the anode to oxidized compounds such as oxygen on the cathode through an external electrical circuit. MFCs produce electricity by using the electrons derived from biochemical reactions catalyzed by bacteria. Comprehensive Biotechnology MFCs can be grouped into two general categories: mediated and unmediated. The first MFCs, demonstrated in the early 20th century, used a mediator: a chemical that transfers electrons from the bacteria in the cell to the anode. Unmediated MFCs emerged in the 1970s; in this type of MFC the bacteria typically have electrochemically active redox proteins such as cytochromes on their outer membrane that can transfer electrons directly to the anode. In the 21st century MFCs have started to find commercial use in wastewater treatment.

Biohydrogen is H2 that is produced biologically. Interest is high in this technology because H2 is a clean fuel and can be readily produced from certain kinds of biomass, including biological waste. Furthermore some photosynthetic microorganisms are capable to produce H2 directly from water splitting using light as energy source.

Fermentation is a type of redox metabolism carried out in the absence of oxygen. During fermentation, organic molecules are catabolized and donate electrons to other organic molecules. In the process, ATP and organic end products are formed.

Aerobic granular reactors (AGR) or Aerobic granular sludge (AGS) are a community of microbial organisms, typically around 0.5-3mm in diameter, that remove carbon, nitrogen, phosphorus and other pollutants in a single sludge system. It can also be used for wastewater treatments. Aerobic granular sludge is composed of bacteria, protozoa and fungi, which allows oxygen to follow in and biologically oxidize organic pollutants. AGS is a type of wastewater treatment process for sewages and/or industrial waste treatment. AGR was first discovered by UK engineers, Edward Ardern and W.T. Lockett who were researching better ways for sewage disposal. Another scientist by the name of Dr. Gilbert Fowler, who was at the University of Manchester working on an experiment based on aeration of sewage in a bottle coated with algae. Eventually, all three scientists were able to collaborate with one another to discover AGR/AGS.

Methanobacteria is a class of archaeans in the kingdom Euryarchaeota. Several of the classes of the Euryarchaeota are methanogens and the Methanobacteria are one of these classes.

Klebsiella aerogenes, previously known as Enterobacter aerogenes, is a Gram-negative, oxidase-negative, catalase-positive, citrate-positive, indole-negative, rod-shaped bacterium. Capable of motility via peritrichous flagella, the bacterium is approximately 1–3 microns in length.

Scenedesmus is a genus of green algae, in the class Chlorophyceae. They are colonial and non-motile. They are one of the most common components of phytoplankton in freshwater habitats worldwide.

Algae fuel, algal biofuel, or algal oil is an alternative to liquid fossil fuels that uses algae as its source of energy-rich oils. Also, algae fuels are an alternative to commonly known biofuel sources, such as corn and sugarcane. When made from seaweed (macroalgae) it can be known as seaweed fuel or seaweed oil.

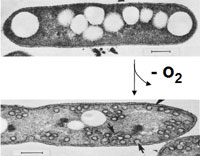

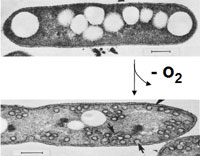

Rhodobacter sphaeroides is a kind of purple bacterium; a group of bacteria that can obtain energy through photosynthesis. Its best growth conditions are anaerobic phototrophy and aerobic chemoheterotrophy in the absence of light. R. sphaeroides is also able to fix nitrogen. It is remarkably metabolically diverse, as it is able to grow heterotrophically via fermentation and aerobic and anaerobic respiration. Such a metabolic versatility has motivated the investigation of R. sphaeroides as a microbial cell factory for biotechnological applications.

Dark fermentation is the fermentative conversion of organic substrate to biohydrogen. It is a complex process manifested by diverse groups of bacteria, involving a series of biochemical reactions using three steps similar to anaerobic conversion. Dark fermentation differs from photofermentation in that it proceeds without the presence of light.

Fermentative hydrogen production is the fermentative conversion of organic substrates to H2. Hydrogen produced in this manner is often called biohydrogen. The conversion is effected by bacteria and protozoa, which employ enzymes. Fermentative hydrogen production is one of several anaerobic conversions.

A Bioelectrochemical reactor is a type of bioreactor where bioelectrochemical processes are used to degrade/produce organic materials using microorganisms. This bioreactor has two compartments: The anode, where the oxidation reaction takes place; And the cathode, where the reduction occurs. At these sites, electrons are passed to and from microbes to power reduction of protons, breakdown of organic waste, or other desired processes. They are used in microbial electrosynthesis, environmental remediation, and electrochemical energy conversion. Examples of bioelectrochemical reactors include microbial electrolysis cells, microbial fuel cells, enzymatic biofuel cells, electrolysis cells, microbial electrosynthesis cells, and biobatteries.

Single cell oil, also known as Microbial oil consists of the intracellular storage lipids, triacyglycerols. It is similar to vegetable oil, another biologically produced oil. They are produced by oleaginous microorganisms, which is the term for those bacteria, molds, algae and yeast, which can accumulate 20% to 80% lipids of their biomass. The accumulation of lipids take place by the end of logarithmic phase and continues during station phase until carbon source begins to reduce with nutrition limitation.

Pratyoosh Shukla is an Indian Microbiologist specialized in Enzyme technology and Protein Bioinformatics. He is presently working as Professor and Coordinator of the School of Biotechnology at the Institute of Science, Banaras Hindu University, Varanasi, India. He was awarded with Indo-USA Research Professor at Department of Environmental Health, College of Medicine, University of Cincinnati, USA in the year 2014 by American Society of Microbiology (ASM) and Indo-U.S. Science and Technology Forum (IUSSTF). He is Fellow of National Academy of Agricultural Sciences (FNAAS), Fellow of Academy of Microbiological Sciences (FAMSc/FAMI), Fellow of Biotech Research Society of India (FBRS).

Autogenerative high-pressure fermentation (AHPD) is a biogas production technique that operates under elevated gas pressure. This pressure is naturally generated by the bacteria and archaea through the gases they release. First described by R. Lindeboom of University of Wageningen (WUR) in 2011, a batch reactor was pressurized to 58 bar, yielding a methane concentration of 96% in the resulting biogas. This method is also commonly referred to as High Pressure Anaerobic Digestion (HPAD) in scientific literature.