Reinforced concrete, also called ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars (rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion.

Rebar, known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

An arch bridge is a bridge with abutments at each end shaped as a curved arch. Arch bridges work by transferring the weight of the bridge and its loads partially into a horizontal thrust restrained by the abutments at either side. A viaduct may be made from a series of arches, although other more economical structures are typically used today.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

Beam bridges are the simplest structural forms for bridge spans supported by an abutment or pier at each end. No moments are transferred throughout the support, hence their structural type is known as simply supported.

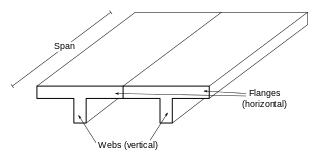

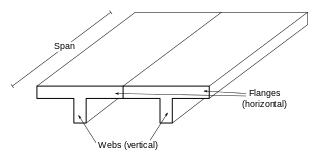

A plate girder bridge is a bridge supported by two or more plate girders.

An abutment is the substructure at the ends of a bridge span or dam supporting its superstructure. Single-span bridges have abutments at each end that provide vertical and lateral support for the span, as well as acting as retaining walls to resist lateral movement of the earthen fill of the bridge approach. Multi-span bridges require piers to support ends of spans unsupported by abutments. Dam abutments are generally the sides of a valley or gorge, but may be artificial in order to support arch dams such as Kurobe Dam in Japan.

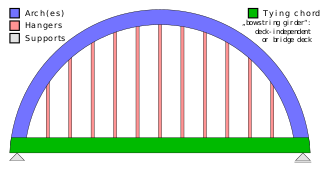

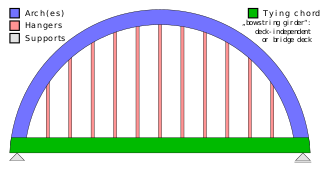

A tied-arch bridge is an arch bridge in which the outward horizontal forces of the arch(es) caused by tension at the arch ends to a foundation are countered by equal tension of its own gravity plus any element of the total deck structure such great arch(es) support. The arch(es) have strengthened chord(s) that run to a strong part of the deck structure or to independent tie-rods below the arch ends.

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridges are plate and box.

Hydrodemolition is a concrete removal technique which utilizes high-pressure water, often containing an abrasive material, to remove deteriorated and sound concrete as well as asphalt and grout. This process provides an excellent bonding surface for repair material and new coating applications. First developed in Europe in the 1980s, this technology has become widely accepted for concrete removal and surface preparation throughout Europe and North America.

The Hampden County Memorial Bridge is a reinforced-concrete arch bridge that spans the Connecticut River between Springfield, Massachusetts and West Springfield, Massachusetts, constructed in 1922. The bridge is owned by Massachusetts Highway Department and is located on Massachusetts Route 147. It spans 209 feet (64 m) and rises 29.71 feet (9.06 m) above the river.

La Vicaria Bridge is a through arch bridge that spans the Segura River, where it meets La Fuensanta Reservoir near Yeste, in the province of Albacete, Spain. It forms part of a future road that will join Yeste with Letur and the neighbouring area to the east. The bridge has 2 vehicle lanes and 2 sidewalks.

A T-beam, used in construction, is a load-bearing structure of reinforced concrete, wood or metal, with a T-shaped cross section. The top of the T-shaped cross section serves as a flange or compression member in resisting compressive stresses. The web of the beam below the compression flange serves to resist shear stress. When used for highway bridges the beam incorporates reinforcing bars in the bottom of the beam to resist the tensile stresses which occur during bending.

The Schierstein Bridge is 1,282-meter (4,206 ft) long, four-lane highway bridge in Germany. It carries Bundesautobahn 643 over the Rhine River between Mainz-Mombach, Rhineland-Palatinate and Wiesbaden-Schierstein, Hesse. Crossing two arms of the Rhine and the intervening island of Rettbergsaue, the bridge is made of six individual structures, including 100 m (330 ft) from prestressed concrete. It was built between 1959 and 1962.

The Mirna Bridge is located between the Nova Vas and Višnjan interchanges of the A9 motorway in Istria, Croatia, spanning the Mirna River and the wide Mirna River valley. It is 1,378 metres (4,521 ft) long and comprises two traffic lanes. The bridge has been open for traffic since June 2005. The bridge is one of the most significant structures on the motorway. The bridge was designed by Zlatko Šavor.

The Old Rhine Bridge at Konstanz spans the Seerhein. It is a combined road and railway bridge. In addition to one track of the High Rhine Railway at kilometer 413.5, it carries the Konzilstraße, the road that connects the borough of Petershausen with the city centre. The road bridge carries two lanes into the city center and three lanes in the other direction. Additionally, there is a bicycle lane in both directions on the left and a sidewalk on the right. In the 19th century, distance markers were placed along the Rhine; they start counting kilometers at this bridge.

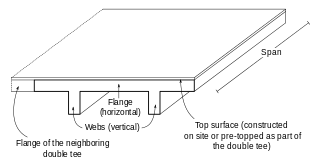

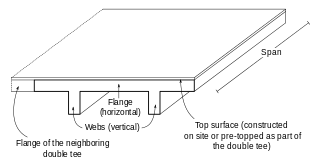

A double tee or double-T beam is a load-bearing structure that resembles two T-beams connected to each other side by side. The strong bond of the flange and the two webs creates a structure that is capable of withstanding high loads while having a long span. The typical sizes of double tees are up to 15 feet (4.6 m) for flange width, up to 5 feet (1.5 m) for web depth, and up to 80 feet (24 m) or more for span length. Double tees are pre-manufactured from prestressed concrete which allows construction time to be shortened.

The Worms Rhine Bridge is a two-track railway bridge that spans the Rhine river to the north of Worms, Germany, forming part of the Worms–Biblis railway.

The Burwell Bridge was a historic bridge on the northern edge of Burwell in Garfield County, Nebraska which was built in 1940–41. It was a steel girder bridge that brings Nebraska Highway 11 over the North Loup River. It is also known as the North Loup River Bridge and denoted as NEHBS Number GFOO-13. It was listed on the National Register of Historic Places in 1992, and was delisted in 2019.

The Gouritz River Bridge on the N2 route between Cape Town and Port Elizabeth is a rigid-frame bridge which crosses the Gouritz River 34 kilometres (21 mi) west of Mossel Bay in the Western Cape.