Masonry is the craft of building a structure with brick, stone, or similar material, including mortar plastering which are often laid in, bound, and pasted together by mortar. The term masonry can also refer to the building units themselves.

Terrazzo is a composite material, poured in place or precast, which is used for floor and wall treatments. It consists of chips of marble, quartz, granite, glass, or other suitable material, poured with a cementitious binder, polymeric, or a combination of both. Metal strips often divide sections, or changes in color or material in a pattern. Additional chips may be sprinkled atop the mix before it sets. After it is cured it is ground and polished smooth or otherwise finished to produce a uniformly textured surface. "Terrazzo" is also often used to describe any pattern similar to the original terrazzo floors. Modern forms of terrazzo include polished concrete.

A road surface or pavement is the durable surface material laid down on an area intended to sustain vehicular or foot traffic, such as a road or walkway. In the past, gravel road surfaces, macadam, hoggin, cobblestone and granite setts were extensively used, but these have mostly been replaced by asphalt or concrete laid on a compacted base course. Asphalt mixtures have been used in pavement construction since the beginning of the 20th century and are of two types: metalled (hard-surfaced) and unmetalled roads. Metalled roadways are made to sustain vehicular load and so are usually made on frequently used roads. Unmetalled roads, also known as gravel roads or dirt roads, are rough and can sustain less weight. Road surfaces are frequently marked to guide traffic.

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials. An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material but might protrude somewhat on the reverse side.

Grout is a dense substance that flows like a liquid yet hardens upon application, and it gets used to fill gaps or to function as reinforcement in existing structures. Grout is generally a mixture of water, cement, and sand, and it frequently gets employed in efforts such as pressure grouting, embedding rebar in masonry walls, connecting sections of precast concrete, filling voids, and sealing joints such as those between tiles. Common uses for grout in the household include filling in tiles of shower floors and kitchen tiles. It is often color tinted when it has to be kept visible and sometimes includes fine gravel when being used to fill large spaces. Unlike other structural pastes such as plaster or joint compound, correctly mixed and applied grout forms a water-resistant seal.

Cobblestone is a natural building material based on cobble-sized stones, and is used for pavement roads, streets, and buildings. Setts, also called Belgian blocks, are often referred to as "cobbles", although a sett is distinct from a cobblestone by being quarried and shaped into a regular form, while cobblestones are naturally occurring forms less uniform in size.

Stucco or render is a construction material made of aggregates, a binder, and water. Stucco is applied wet and hardens to a very dense solid. It is used as a decorative coating for walls and ceilings, exterior walls, and as a sculptural and artistic material in architecture. Stucco can be applied on construction materials such as metal, expanded metal lath, concrete, cinder block, or clay brick and adobe for decorative and structural purposes.

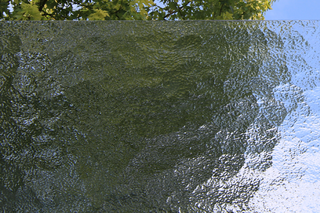

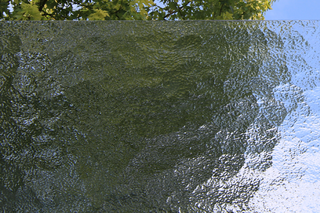

Glass brick, also known as glass block, is an architectural element made from glass. The appearance of glass blocks can vary in color, size, texture and form. Glass bricks provide visual obscuration while admitting light. The modern glass block was developed from pre-existing prism lighting principles in the early 1900s to provide natural light in manufacturing plants. Today glass blocks are used in walls, skylights, and sidewalk lights.

Photoengraving is a process that uses a light-sensitive photoresist applied to the surface to be engraved to create a mask that protects some areas during a subsequent operation which etches, dissolves, or otherwise removes some or all of the material from the unshielded areas of a substrate. Normally applied to metal, it can also be used on glass, plastic and other materials.

Flocking is the process of depositing many small fiber particles onto a surface. It can also refer to the texture produced by the process, or to any material used primarily for its flocked surface. Flocking of an article can be performed for the purpose of increasing its value. It can also be performed for functional reasons including insulation, slip-or-grip friction, retention of a liquid film, and low reflectivity.

Cathedral glass is the name given commercially to monochromatic sheet glass. It is thin by comparison with 'slab glass', may be coloured, and is textured on one side. The name draws from the fact that windows of stained glass were a feature of medieval European cathedrals from the 10th century onward.

Waterproofing is the process of making an object, person or structure waterproof or water-resistant so that it remains relatively unaffected by water or resisting the ingress of water under specified conditions. Such items may be used in wet environments or underwater to specified depths.

Dimension stone is natural stone or rock that has been selected and finished to specific sizes or shapes. Color, texture and pattern, and surface finish of the stone are also normal requirements. Another important selection criterion is durability: the time measure of the ability of dimension stone to endure and to maintain its essential and distinctive characteristics of strength, resistance to decay, and appearance.

A countertop, also counter top, counter, benchtop, worktop or kitchen bench, bunker is a raised, firm, flat, and horizontal surface. They are built for work in kitchens or other food preparation areas, bathrooms or lavatories, and workrooms in general. The surface is frequently installed upon and supported by cabinets, positioned at an ergonomic height for the user and the particular task for which it is designed. A countertop may be constructed of various materials with different attributes of functionality, durability and aesthetics, and may have built-in appliances, or accessory items relative to the intended application.

Béton brut is architectural concrete that is left unfinished after being cast, displaying the patterns and seams imprinted on it by the formwork. Béton brut is not a material itself, but rather a way of using concrete. The term comes from French and means "raw concrete".

Decorative concrete is the use of concrete as not simply a utilitarian medium for construction but as an aesthetic enhancement to a structure, while still serving its function as an integral part of the building itself such as floors, walls, driveways, and patios.

Polished plaster is a term for the finish of some plasters and for the description of new and updated forms of traditional Italian plaster finishes. The term covers a whole range of decorative plaster finishes, from the very highly polished Venetian plaster and Marmorino to the rugged look of textured polished plasters. Polished plaster itself tends to consist of slaked lime, marble dust, and/or marble chips, which give each plaster its distinctive look. A lime-based polished plaster may contain over 40% of marble powder.

Hardfacing is a metalworking process where harder or tougher material is applied to a base metal. It is welded to the base material, and generally takes the form of specialized electrodes for arc welding or filler rod for oxyacetylene and gas tungsten arc welding. Powder metal alloys are used in plasma-transferred arc (PTA), also called powder plasma welding, and thermal spray processes like high-velocity oxygen fuel coating, plasma spray, spray and fuse, etc. Submerged arc welding, flux core arc welding (FCAW) and metal inert gas (MIG) / metal active gas (MAG) use continuously fed wire varying in diameter depending on the process and current. The strip cladding process uses strips from 50 mm wide to 125 mm with a thickness of 0.5mm. Open arc welding uses a continuously fed tubular electrode which may or may not contain flux.

Postage stamp paper is the foundation or substrate of the postage stamp to which the ink for the stamp's design is applied to one side and the adhesive is applied to the other. The paper is not only the foundation of the stamp but it has also been incorporated into the stamp's design, has provided security against fraud and has aided in the automation of the postal delivery system.

Chalk paint is a water-based, decorative paint invented by Annie Sloan which may be applied over almost any surface. It requires very little preparation and needs a topcoat to avoid flaking. Chalk paints are also used by utility companies to mark road surfaces.