In electrical engineering, the power factor of an AC power system is defined as the ratio of the real power absorbed by the load to the apparent power flowing in the circuit. Real power is the average of the instantaneous product of voltage and current and represents the capacity of the electricity for performing work. Apparent power is the product of RMS current and voltage. Due to energy stored in the load and returned to the source, or due to a non-linear load that distorts the wave shape of the current drawn from the source, the apparent power may be greater than the real power, so more current flows in the circuit than would be required to transfer real power alone. A power factor magnitude of less than one indicates the voltage and current are not in phase, reducing the average product of the two. A negative power factor occurs when the device generates real power, which then flows back towards the source.

A high-voltage direct current (HVDC) electric power transmission system uses direct current (DC) for electric power transmission, in contrast with the more common alternating current (AC) transmission systems.

A rectifier is an electrical device that converts alternating current (AC), which periodically reverses direction, to direct current (DC), which flows in only one direction. The reverse operation is performed by an inverter.

A power inverter, inverter or invertor is a power electronic device or circuitry that changes direct current (DC) to alternating current (AC). The resulting AC frequency obtained depends on the particular device employed. Inverters do the opposite of rectifiers which were originally large electromechanical devices converting AC to DC.

A flexible alternating current transmission system (FACTS) is a system composed of static equipment used for the alternating current (AC) transmission of electrical energy. It is meant to enhance controllability and increase power transfer capability of the network. It is generally a power electronics-based system.

A static VAR compensator (SVC) is a set of electrical devices for providing fast-acting reactive power on high-voltage electricity transmission networks. SVCs are part of the flexible AC transmission system device family, regulating voltage, power factor, harmonics and stabilizing the system. A static VAR compensator has no significant moving parts. Prior to the invention of the SVC, power factor compensation was the preserve of large rotating machines such as synchronous condensers or switched capacitor banks.

An HVDC converter station is a specialised type of substation which forms the terminal equipment for a high-voltage direct current (HVDC) transmission line. It converts direct current to alternating current or the reverse. In addition to the converter, the station usually contains:

In an electric circuit, instantaneous power is the time rate of flow of energy past a given point of the circuit. In alternating current circuits, energy storage elements such as inductors and capacitors may result in periodic reversals of the direction of energy flow. Its SI unit is the watt.

A variable-frequency drive, variable-speed drives, AC drives, micro drives, inverter drives, or drives) is a type of AC motor drive that controls speed and torque by varying the frequency of the input electricity. Depending on its topology, it controls the associated voltage or current variation.

An induction generator or asynchronous generator is a type of alternating current (AC) electrical generator that uses the principles of induction motors to produce electric power. Induction generators operate by mechanically turning their rotors faster than synchronous speed. A regular AC induction motor usually can be used as a generator, without any internal modifications. Because they can recover energy with relatively simple controls, induction generators are useful in applications such as mini hydro power plants, wind turbines, or in reducing high-pressure gas streams to lower pressure.

A static synchronous compensator (STATCOM), originally known as a static synchronous condenser (STATCON), is a regulating device shunt-connected to alternating current electricity transmission network. It is based on a power electronics voltage-source converter and can act as either a source or sink of reactive AC power to an electricity network. If connected to a source of power it can also provide active AC power. It is a member of the FACTS family of devices, that became possible in 1990s due to availability of powerful gate turn-off thyristors (GTO). STATCOM is inherently modular and electable.

An electric power system is a network of electrical components deployed to supply, transfer, and use electric power. An example of a power system is the electrical grid that provides power to homes and industries within an extended area. The electrical grid can be broadly divided into the generators that supply the power, the transmission system that carries the power from the generating centers to the load centers, and the distribution system that feeds the power to nearby homes and industries.

The GK Dürnrohr was a high-voltage direct current back-to-back scheme west of Dürnrohr substation, which was used for the energy exchange between Austria and Czechoslovakia between 1983 and 1996. The installation is no longer in use.

The Sakuma Dam is a dam on the Tenryū River, located on the border of Toyone, Kitashitara District, Aichi Prefecture on the island of Honshū, Japan. It is one of the tallest dams in Japan and supports a 350 MW hydroelectric power station. Nearby a frequency converter station is installed, allowing interchange of power between Japan's 50 Hz and 60 Hz AC networks.

The Levis De-Icer is a High voltage direct current (HVDC) system, aimed at de-icing multiple AC power lines in Quebec, Canada. It is the only HVDC system not used for power transmission.

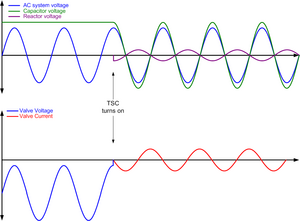

In an electric power transmission system, a thyristor-controlled reactor (TCR) is a reactance connected in series with a bidirectional thyristor valve. The thyristor valve is phase-controlled, which allows the value of delivered reactive power to be adjusted to meet varying system conditions. Thyristor-controlled reactors can be used for limiting voltage rises on lightly loaded transmission lines. Another device which used to be used for this purpose is a magnetically controlled reactor (MCR), a type of magnetic amplifier otherwise known as a transductor.

The Chandrapur back-to-back HVDC station is a back-to-back HVDC connection between the western and southern regions in India, located close to the city of Chandrapur. Its main purpose is to export power from the Chandrapur Super Thermal Power Station to the southern region of the Indian national power grid. It is owned by Power Grid Corporation of India.

An HVDC converter converts electric power from high voltage alternating current (AC) to high-voltage direct current (HVDC), or vice versa. HVDC is used as an alternative to AC for transmitting electrical energy over long distances or between AC power systems of different frequencies. HVDC converters capable of converting up to two gigawatts (GW) and with voltage ratings of up to 900 kilovolts (kV) have been built, and even higher ratings are technically feasible. A complete converter station may contain several such converters in series and/or parallel to achieve total system DC voltage ratings of up to 1,100 kV.

A line trap, also known as wave trap, or high-frequency stopper, is a maintenance-free parallel resonant circuit, mounted inline on high-voltage (HV) AC transmission power lines to prevent the transmission of high frequency carrier signals of power line communication to unwanted destinations. Line traps are cylinder-like structures connected in series with HV transmission lines. A line trap is also called a wave trap.

This glossary of power electronics is a list of definitions of terms and concepts related to power electronics in general and power electronic capacitors in particular. For more definitions in electric engineering, see Glossary of electrical and electronics engineering. For terms related to engineering in general, see Glossary of engineering.