Acrylic paint is a fast-drying paint made of pigment suspended in acrylic polymer emulsion and plasticizers, silicone oils, defoamers, stabilizers, or metal soaps. Most acrylic paints are water-based, but become water-resistant when dry. Depending on how much the paint is diluted with water, or modified with acrylic gels, mediums, or pastes, the finished acrylic painting can resemble a watercolor, a gouache, or an oil painting, or it may have its own unique characteristics not attainable with other media.

Paint is a material or mixture that, when applied to a solid material and allowed to dry, adds a film-like layer. As art, this is used to create an image or images known as a painting. Paint can be made in many colors and types. Most paints are either oil-based or water-based, and each has distinct characteristics.

Waxes are a diverse class of organic compounds that are lipophilic, malleable solids near ambient temperatures. They include higher alkanes and lipids, typically with melting points above about 40 °C (104 °F), melting to give low viscosity liquids. Waxes are insoluble in water but soluble in nonpolar organic solvents such as hexane, benzene and chloroform. Natural waxes of different types are produced by plants and animals and occur in petroleum.

Varnish is a clear transparent hard protective coating or film. It is not to be confused with wood stain. It usually has a yellowish shade due to the manufacturing process and materials used, but it may also be pigmented as desired. It is sold commercially in various shades.

Lacquer is a type of hard and usually shiny coating or finish applied to materials such as wood or metal. It is most often made from resin extracted from trees and waxes and has been in use since antiquity.

Linseed oil, also known as flaxseed oil or flax oil, is a colorless to yellowish oil obtained from the dried, ripened seeds of the flax plant. The oil is obtained by pressing, sometimes followed by solvent extraction.

Oil paint is a type of slow-drying paint that consists of particles of pigment suspended in a drying oil, commonly linseed oil. Oil paint also has practical advantages over other paints, mainly because it is waterproof.

Linoleum is a floor covering made from materials such as solidified linseed oil (linoxyn), pine resin, ground cork dust, sawdust, and mineral fillers such as calcium carbonate, most commonly on a burlap or canvas backing. Pigments are often added to the materials to create the desired color finish. Commercially, the material has been largely replaced by sheet vinyl flooring, although in the UK and Australia this is often still referred to as "lino".

A drying oil is an oil that hardens to a tough, solid film after a period of exposure to air, at room temperature. The oil hardens through a chemical reaction in which the components crosslink by the action of oxygen. Drying oils are a key component of oil paint and some varnishes. Some commonly used drying oils include linseed oil, tung oil, poppy seed oil, perilla oil, castor oil and walnut oil. The use of natural drying oils has declined over the past several decades, as they have been replaced by alkyd resins and other binders.

Water-miscible oil paint is oil paint either engineered or to which an emulsifier has been added, allowing it to be thinned and cleaned up with water. These paints make it possible to avoid using, or at least reduce volatile organic compounds such as turpentine that may be harmful if inhaled. Water-miscible oil paint can be mixed and applied using the same techniques as traditional oil-based paint, but while still wet it can be removed from brushes, palettes, and rags with ordinary soap and water. One of the ways its water solubility comes from is the use of an oil medium in which one end of the molecule has been engineered to be hydrophilic and thus bind loosely to water molecules, as in a solution. This type of paint is different to those that are engineered to enable cleaning of brushes and application equipment in water but are not in themselves water reducible.

Walnut oil is oil extracted from walnuts, Juglans regia. The oil contains polyunsaturated fatty acids, monounsaturated fatty acids, and saturated fats.

Japan black is a lacquer or varnish suitable for many substrates but known especially for its use on iron and steel. It can also be called japan lacquer and Brunswick black. Its name comes from the association between the finish and Japanese products in the West. Used as a verb, japan means "to finish in japan black". Thus japanning and japanned are terms describing the process and its products.

French polishing is a wood finishing technique that results in a very high gloss surface, with a deep colour and chatoyancy. French polishing consists of applying many thin coats of shellac dissolved in denatured alcohol using a rubbing pad lubricated with one of a variety of oils. The rubbing pad is made of absorbent cotton or wool cloth wadding inside of a piece of fabric and is commonly referred to as a fad, also called a rubber, tampon, or muñeca.

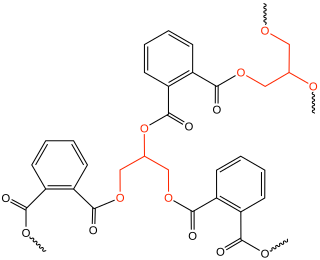

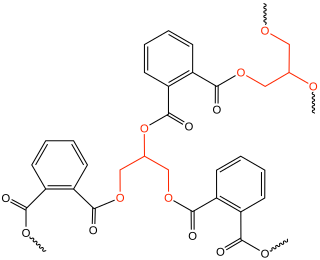

An alkyd is a polyester resin modified by the addition of fatty acids and other components. Alkyds are derived from polyols and organic acids including dicarboxylic acids or carboxylic acid anhydride and triglyceride oils. The term alkyd is a modification of the original name "alcid", reflecting the fact that they are derived from alcohol and organic acids. The inclusion of a fatty acid confers a tendency to form flexible coatings. Alkyds are used in paints, varnishes and in moulds for casting. They are the dominant resin or binder in most commercial oil-based coatings. Approximately 200,000 tons of alkyd resins are produced each year. The original alkyds were compounds of glycerol and phthalic acid sold under the name Glyptal. These were sold as substitutes for the darker-colored copal resins, thus creating alkyd varnishes that were much paler in colour. From these, the alkyds that are known today were developed.

Wood flooring is any product manufactured from timber that is designed for use as flooring, either structural or aesthetic. Wood is a common choice as a flooring material and can come in various styles, colors, cuts, and species. Bamboo flooring is often considered a form of wood flooring, although it is made from bamboo rather than timber.

Danish oil is a wood finishing oil, often made of tung oil or polymerized linseed oil. Because there is no defined formulation, its composition varies among manufacturers.

Waxed cotton is cotton impregnated with a paraffin or natural beeswax based wax, woven into or applied to the cloth. Popular from the 1920s to the mid-1950s, the product, which developed from the sailing industry in England and Scotland, became commonly used for waterproofing. It has been replaced by more modern materials but is still used by the country sports community. There are two main drawbacks: waxed fabric is not very breathable, and it tends to be heavier and bulkier than modern synthetic waterproof materials.

A finishing oil is a vegetable oil used for wood finishing.

Oilcloth, also known as enameled cloth or American cloth, is close-woven cotton duck or linen cloth with a coating of boiled linseed oil to make it waterproof.